We believe that extended time period partnership can be a result of high quality, worth added service, wealthy knowledge and personal contact for Factory Price Galvanized Ridge Roofing Sheet/cap Gutter Roll Forming Machine, To significantly improve our assistance quality, our company imports a large number of international advanced devices. Welcome clients from your home and abroad to simply call and inquire!

We believe that extended time period partnership can be a result of high quality, worth added service, wealthy knowledge and personal contact for Galvanized Ridge Roofing Sheet/cap Gutter Roll Forming Machine, Roof Panel Ridge Cap Cold Roll Forming Machine, Roof Panel Ridge Cap Tile Machine, Our company sticks to the principle of “high quality, reasonable price and timely delivery”. We sincerely hope to establish good cooperative relationships with our new and old business partners from all parts of the world. We hope to work with you and serve you with our excellent products and services. Welcome to join us!

Description:

Gutter Roll Forming Machine normally work with 0.4-0.6mm thickness raw material to make gutters and drains. Normal working speed is aroun 10-20m/min. We adopt torri stand structure, it’s more beautiful and more table when the machine working.

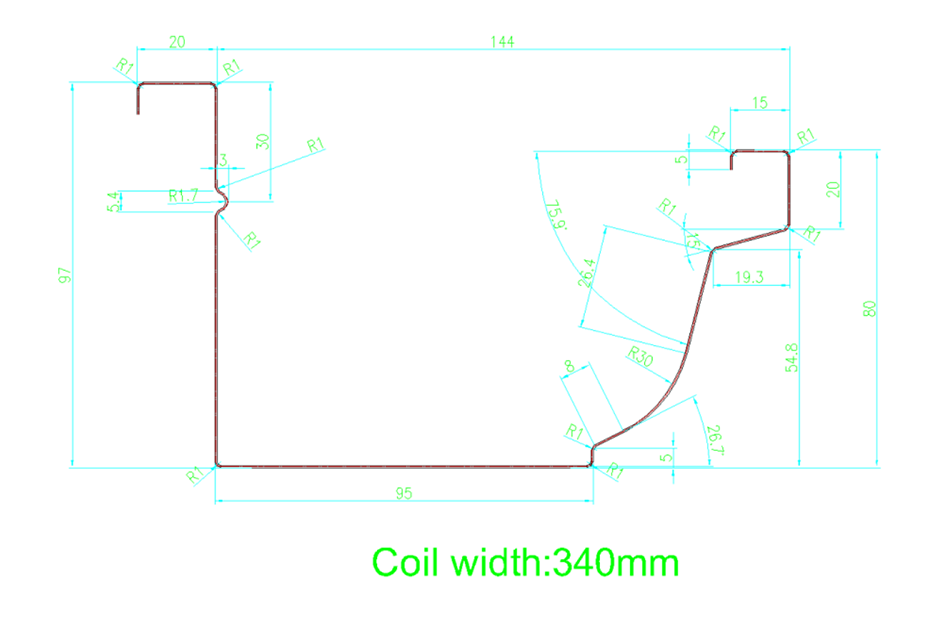

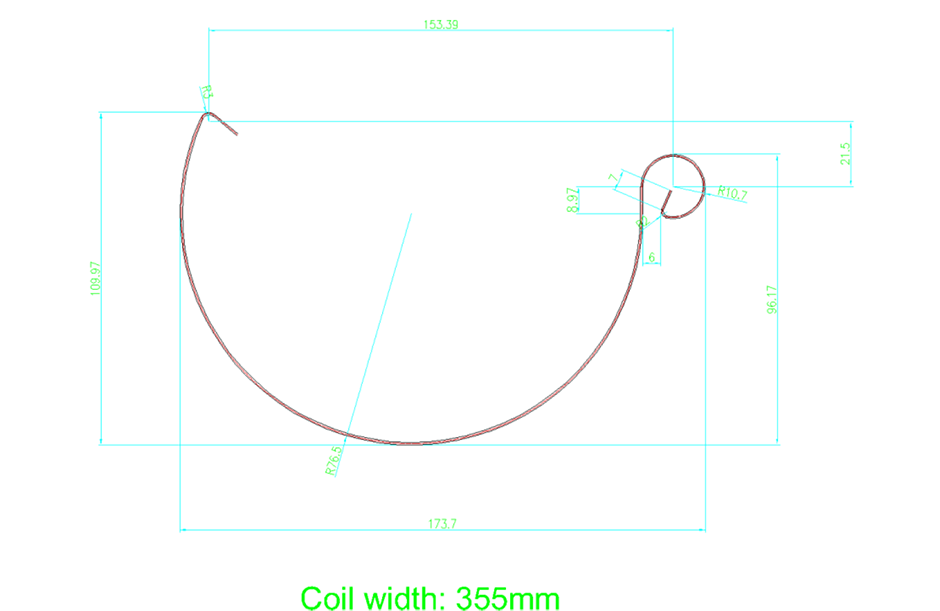

Profile:

Technical specification:

|

Gutter roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.4-0.6 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

19 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

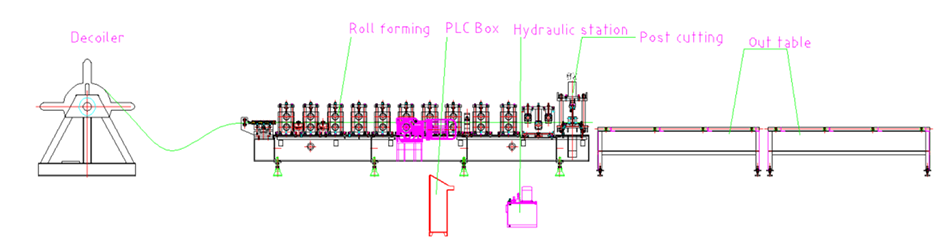

Flow Chart:

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Send your message to us:

-

Big discounting China Ladder Type Cable Tray Ro...

-

2019 Good Quality China Low Noise Economical Pr...

-

New Arrival China Decorative Rockwool Sandwich ...

-

Hot Selling for China Metal Steel Cable Tray Ma...

-

Wholesale OEM/ODM China High Precision C Solar ...

-

Massive Selection for China Tile Roof Panel Dou...