With this motto in mind, we have now grow to be one among quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for Rapid Delivery for China Glazed Tile/Roof Panel Double Layer Cold Roll Forming Machine, For additional queries or should you might have any question regarding our goods, make sure you do not hesitate to call us.

With this motto in mind, we have now grow to be one among quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for China Glazed Tile Roll Forming Machine, Corrugated Roll Forming Machine, Double Layer Roll Forming Machine, metal roof forming machine, metal roof panel machine, Metal Roof Roll Forming Machine, Metal Roofing Machine, Metal Roofing Machines, roll forming roofing machine, Roof Forming Machine, roof panel machine, Roof Panel Roll Forming Machine, Roofing Sheet Making Machine, roofing sheets manufacturing machine, wall panel roll former, We provide good quality but unbeatable low price and the best service. Welcome to post your samples and color ring to us .We are going to produce the items according to your request. If you are interested in any items we offer, please feel free to contact us directly by mail, fax, telephone or internet. We’ve been here to answer your questions from Monday to Saturday and looking forward to cooperating with you.

Description:

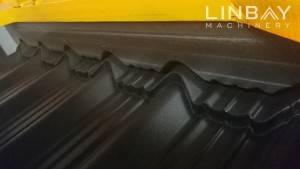

Double Layer Roll Forming Machine can produce two different profile drawings in one machine, it can save more room and of course more economy compared with two different machines.

You can choose two different kind of profile drawings as well as corrugated sheet drawing, but one time only can produce one layer profile . There is one clutch as one side of the machine, and we just need simply to move one handle wheel to make other layer profile.

Technical specification:

|

Double Layer Corrugated sheet roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.3-0.8 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

20-23 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron stationOr torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

Flow Chart:

Manual decoiler–feeding–roll forming–hydraulic cutting–out table

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Send your message to us:

-

Super Purchasing for China Cut to Length Machine

-

OEM Customized Used Roller Shutter C Purlin Ste...

-

Wholesale OEM/ODM China High Precision C Solar ...

-

100% Original Full Automatic Metal Steel Roofin...

-

Quality Inspection for China Two Shapes Strut C...

-

2019 New Style China PPGI Roof and Wall Panel S...