Assume full responsibility to meet all demands of our clients; achieve continuous advancements by promoting the growth of our clients; become the final permanent cooperative partner of clients and maximize the interests of clients for China Gold Supplier for China Water Gutter Roll Forming Machinery, We guaranteed high quality, if clients were not satisfied with the products’ quality, you can return inside 7days with their original states.

Assume full responsibility to meet all demands of our clients; achieve continuous advancements by promoting the growth of our clients; become the final permanent cooperative partner of clients and maximize the interests of clients for China Seamless Gutter Machine, corrugated roof panel, corrugated wall panel, double layer roof, downspout pipe roll forming machine, downspout pipe round, downspout pipe square, elbow forming machine, Gutter Machine, gutter roll former, Gutter Roll Forming Machine, K span, ridge cap, ridge cap production line, Roll Forming Machine, roof panel, roof tile, roof tile cold bending machine, standing seam, Standing Seam Roll Forming Machine, trapezoidal roof panel forming machiney, wall panel, Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

Description

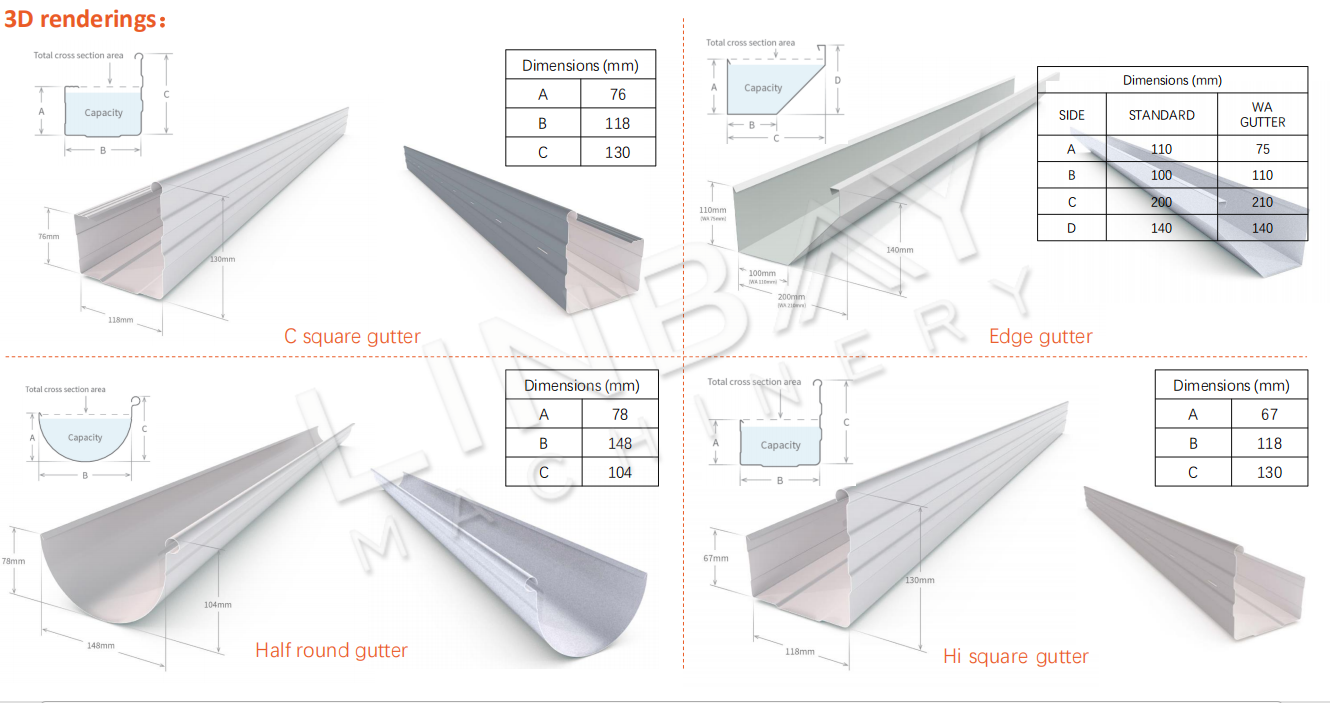

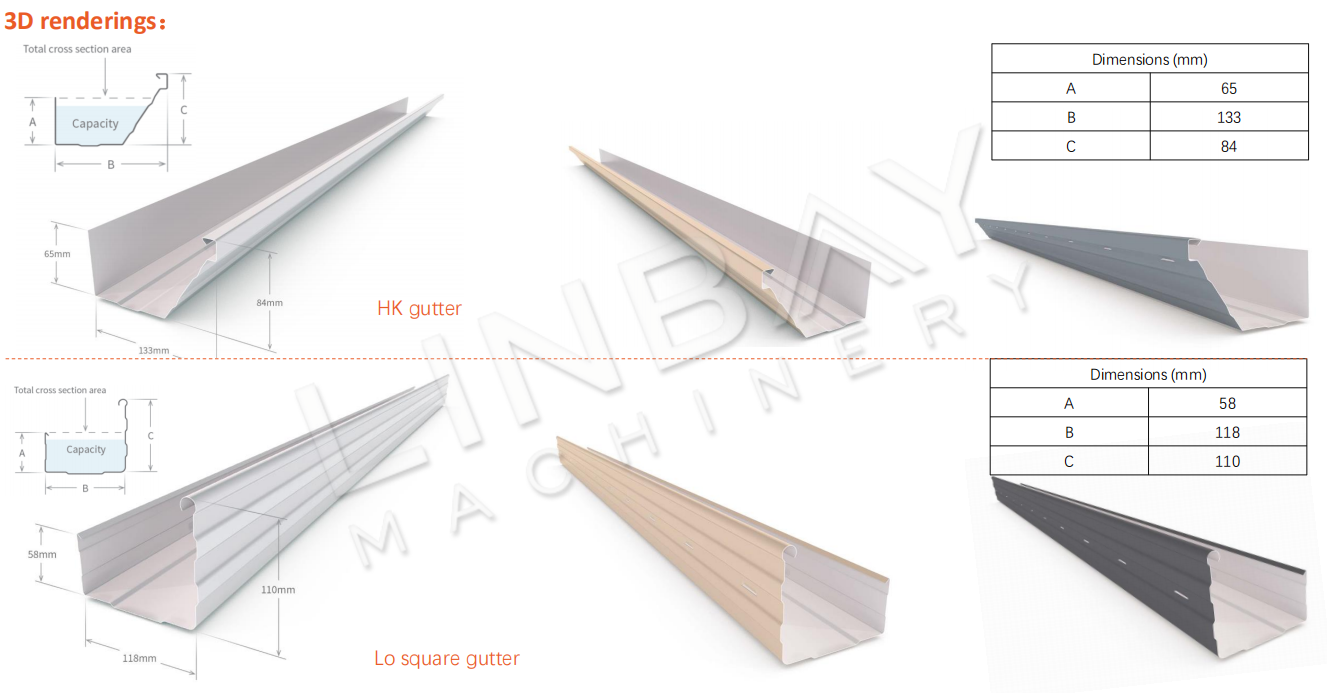

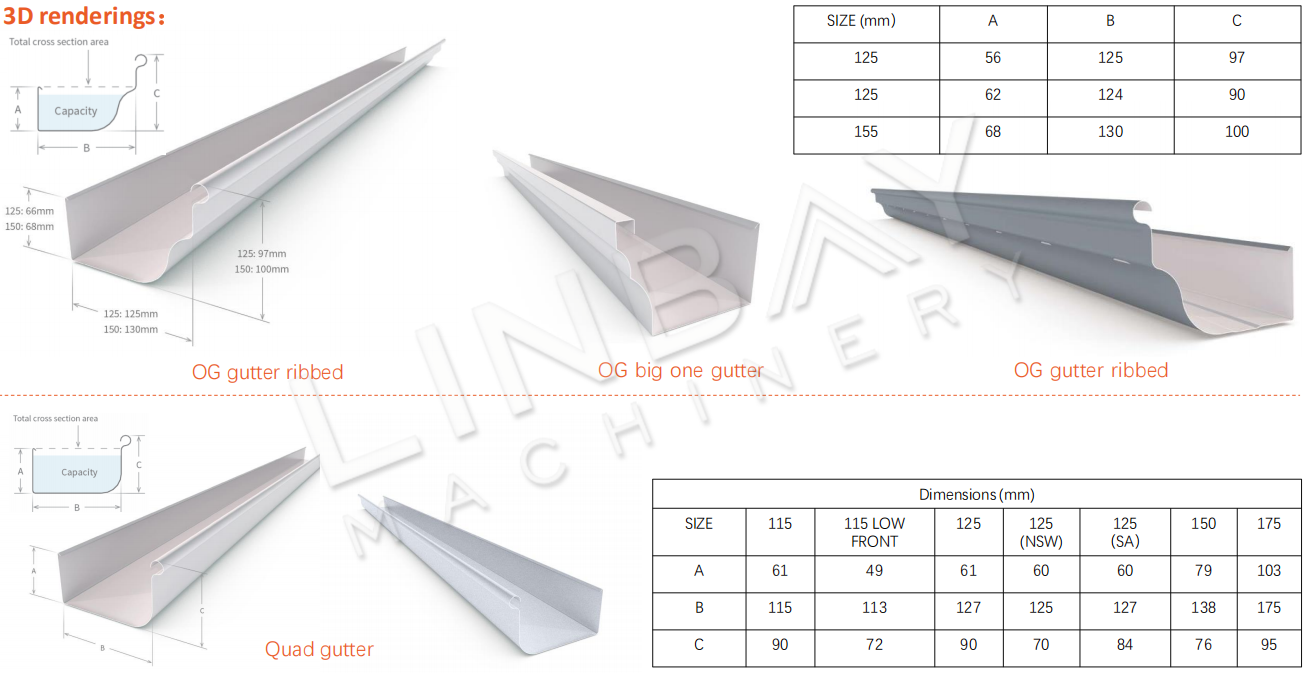

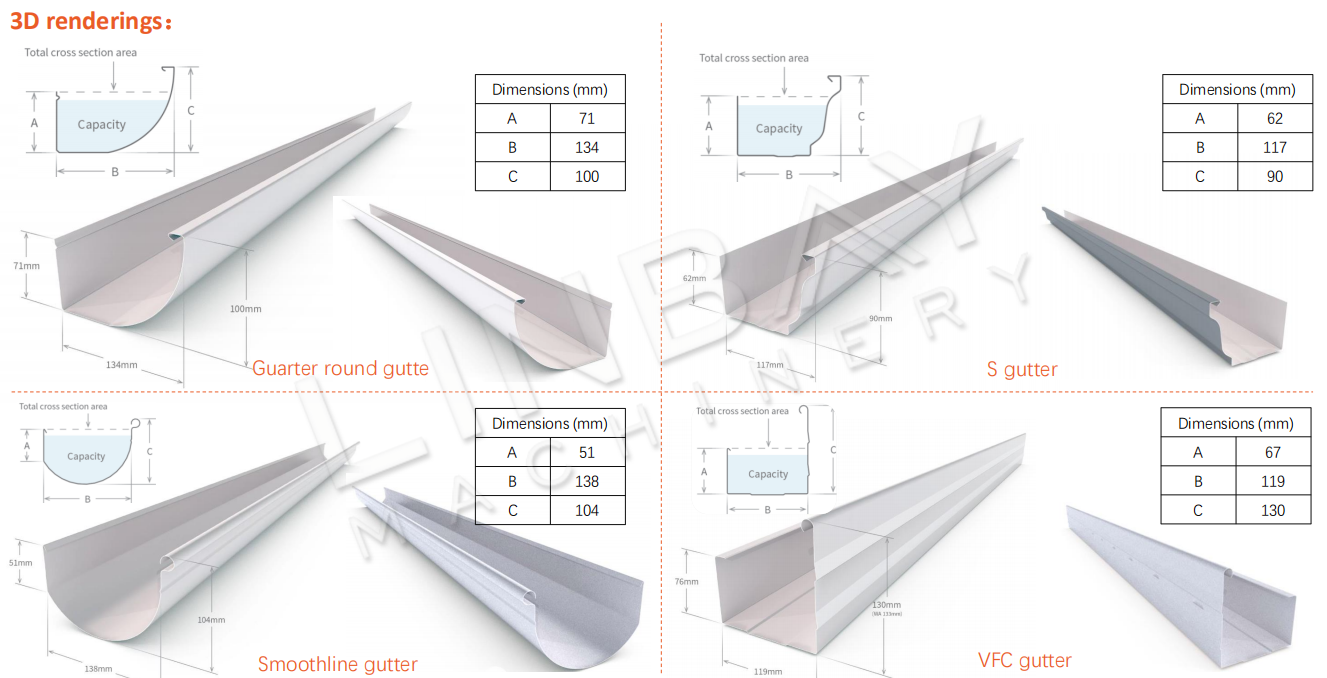

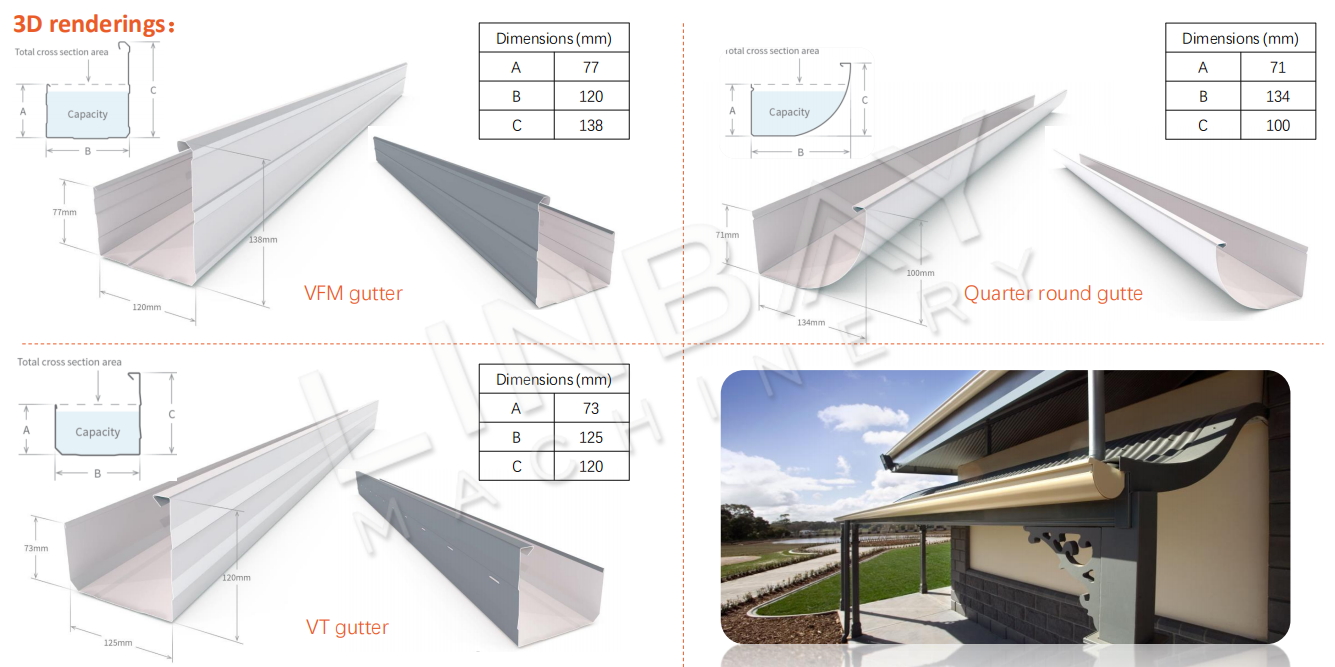

Linbay gutter roll forming machine is suitable for companies who work on rainwater goods system. Machinable thickness of gutter could be 0.4mm-0.6mm or as you request with raw material: Aluminum, Galvanized steel, Painted steel, Galvalume and Cooper etc. We could make machine solution for Quad Gutter, Quarter Round Gutter, C-Square Gutter, Hi-Square Gutter, Lo-Square Gutter, VC Gutter, VF Gutter, VFC Gutter, VFM Gutter, VT Gutter, OG Gutter, OG Big One Gutter, S Gutter, Half Round Gutter, Smoothline Gutter, Round Flo Gutter or according to your profile drawing.

Linbay gutter roll forming machine has been exported to Russia, Australia, Philippines, Vietnam and Mexico, specially to Australia.

In rainwater goods system, we are able to manufacture more machines like round downspout pipe roll forming machine, square downspout pipe roll forming machine, separate elbow machine etc.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of Linbay Machinery will ensure you obtain perfectly functional profiles.

Application

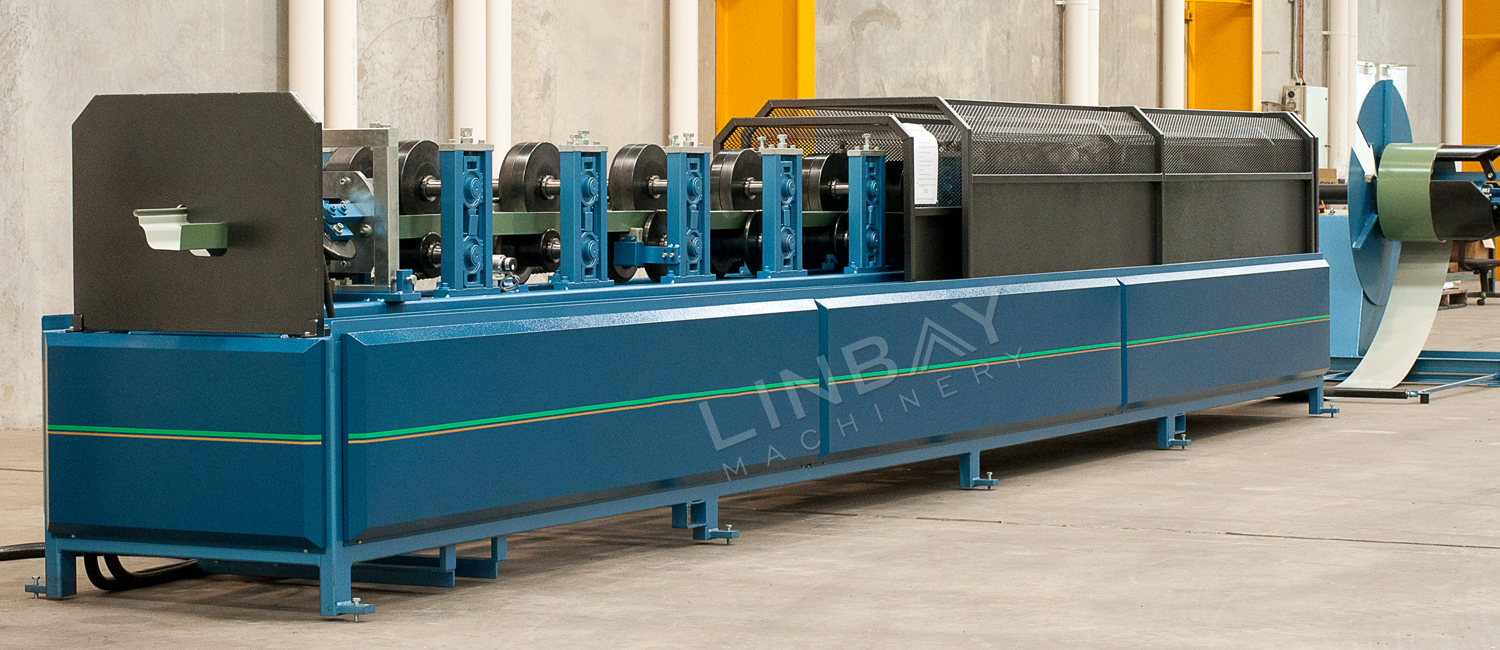

Machines’ pictures

Real Case A

Description:

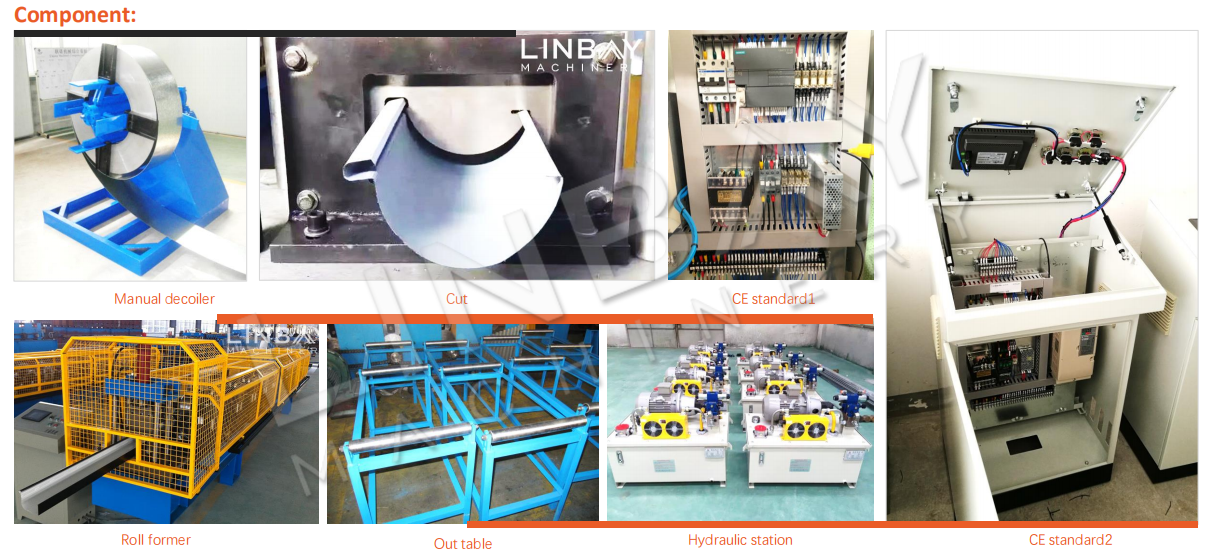

This edge gutter roll forming machine was exported to Australia on 2016. We used all components that meet Australian standards, specially we pay more attention to electric cabinet. We have exported slitting line, gutter roll forming machine, cable tray roll forming machine, roof/wall panel roll forming machine and door frame roll forming machine to Australia so far.

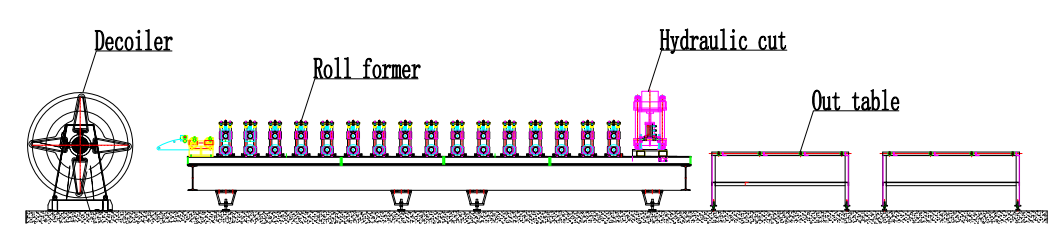

Whole Production Line of Gutter Roll Forming Machine

Technical Specifications

|

Gutter Roll Forming Machine |

||

| Machinable Material : | A) Aluminum | Thickness(MM): 0.4-0.6 |

| B) Copper | ||

| C) Galvanized steel | ||

| D) Galvalume | ||

| Yield strength : | 250 – 350 Mpa | |

| Tensil stress : | 300 Mpa-500 Mpa | |

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Forming station : | 16-20 | * According to your profile drawings |

| Main machine motor brand : | Shanghai Dedong (Sino-Germany Brand) | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Wall panel station | * Torri station (Optional) |

| Forming speed : | 10-15 (M/MIN) | * Or according to your profile drawings |

| Rollers’ material : | Steel #45 | * GCr 15 (Optional) |

| Cutting system : | Post-cutting | |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz 3ph | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

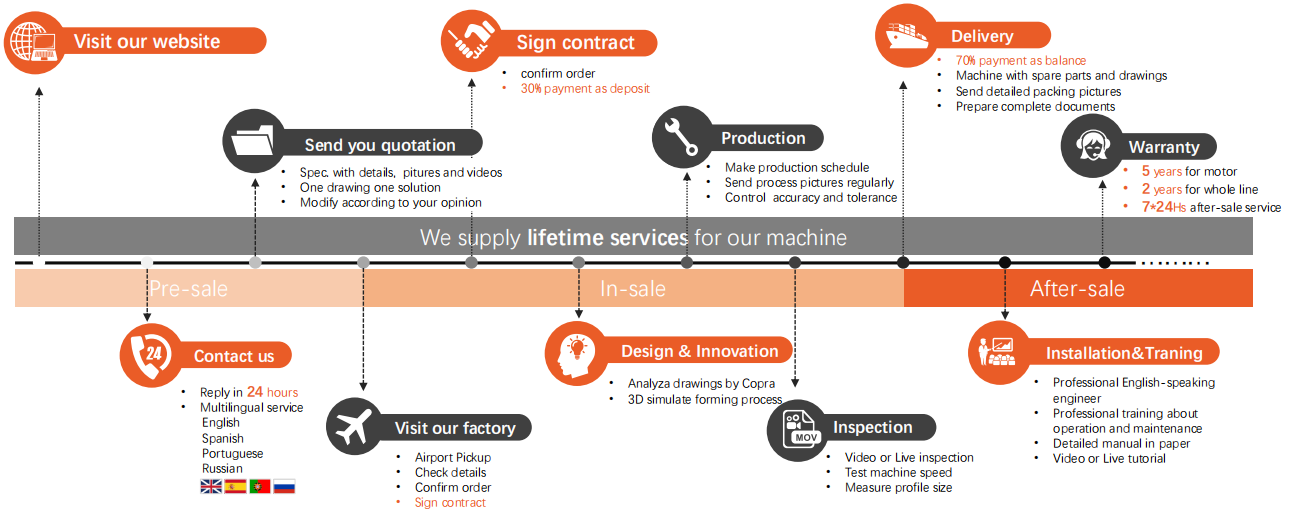

Purchase Service

Q&A

1.Q: What kinds of experience do you have in producing gutter roll forming machine?

A: We have experience of exporting our gutter roll formers to South Africa, Australia, Kyrghyzstan, Russia, Southeast Asia, Mexico and etc. We have produced OG big one gutter, half round gutter, edge gutter, HK gutter, VG gutter and C square gutter.

2.Q: What parts of rainwater system are included?

A: Rainwater system mainly consist of gutter roll forming machine and downspout pipe roll forming machine. And all product shapes can be customized according to your requirements, whether it is a square pipe, a round pipe or a heterogeneous pipe.

3.Q: What is delivery time of gutter roll forming machine?

A: 40 days to 50 days depends on your drawing.

4.Q: What is your machine speed?

A: Machine’s working speed depends on drawing. Normally line forming speed is around 12m/min.

5.Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6.Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

7. Q: How to visit our company when you arrived in China?

A: –Arrived at Beijing International Airport: Take the high-speed train from Beijing South Railway Station to Wuxi East Railway Station. It would take around 4 hours, we will wait for you at Wuxi East Railway Station and pick you up to our factory.

–Arrived at Shanghai Pudong International Airport or Shanghai Hongqiao International Airport: Take the high-speed train from Shanghai Hongqiao Station. It would take around 30 minutes, we will wait for you at Wuxi East Railway Station and pick you up to our factory.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Send your message to us:

-

China Cheap price China Safe Door Frame Roll Fo...

-

Discount wholesale China Strong Practicability ...

-

Factory wholesale China Steel Coil Automatic Sl...

-

Fixed Competitive Price China Color Steel Sheet...

-

Professional China High Speed Fully Automatic H...

-

Chinese wholesale China Steel Coil Rewinder Sli...