Perfil

Lihlahisoa tsena tsa marako a tšepe li sebelisoa lits'ebetsong tse fapaneng, joalo ka mabota a behang meroalo, mabota a likharetene, li-joists tsa fatše le lithapo tsa marulelo.

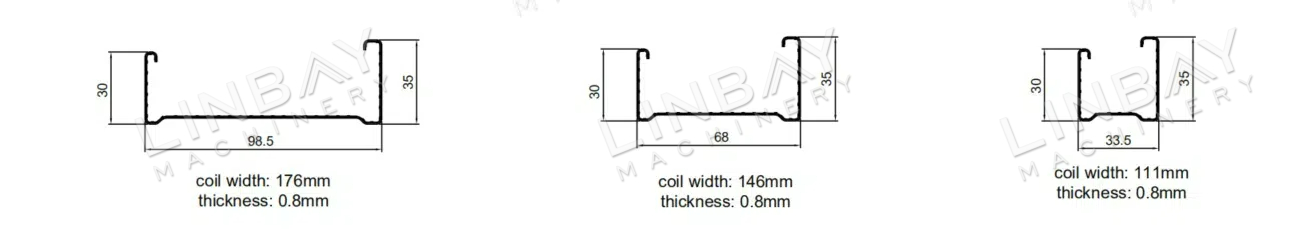

Li-stud, lipina, li-omega, le li-profiles tse ling tsa light gauge hangata li hlahisoa ke mela e batang ea roll. Litekanyo tsa profil le lipaterone tsa ho otla li ka etsoa ka mokhoa o ikhethileng.

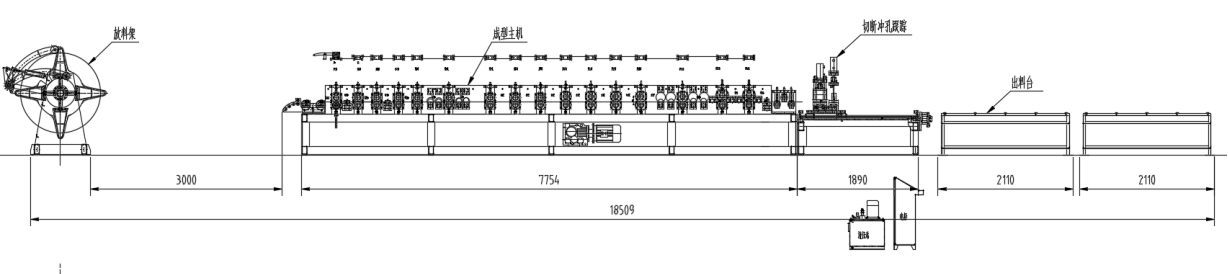

Chate ea 'nete ea Phallo

Decoiler--Guiding--Roll former--Flying hydraulic punch--Flying hydraulic cut--Out table

Taba ea 'nete-Mekhahlelo e ka Sehloohong ea Tekheniki

1.Lebelo la Line: 0-15m / min ka perforation, e fetohang

2.Ho theha lebelo: 0-40m / min

3.Lisebelisoa tse loketseng: Tšepe e entsoeng ka galvanized

4.Material botenya: 0.4-0.8mm

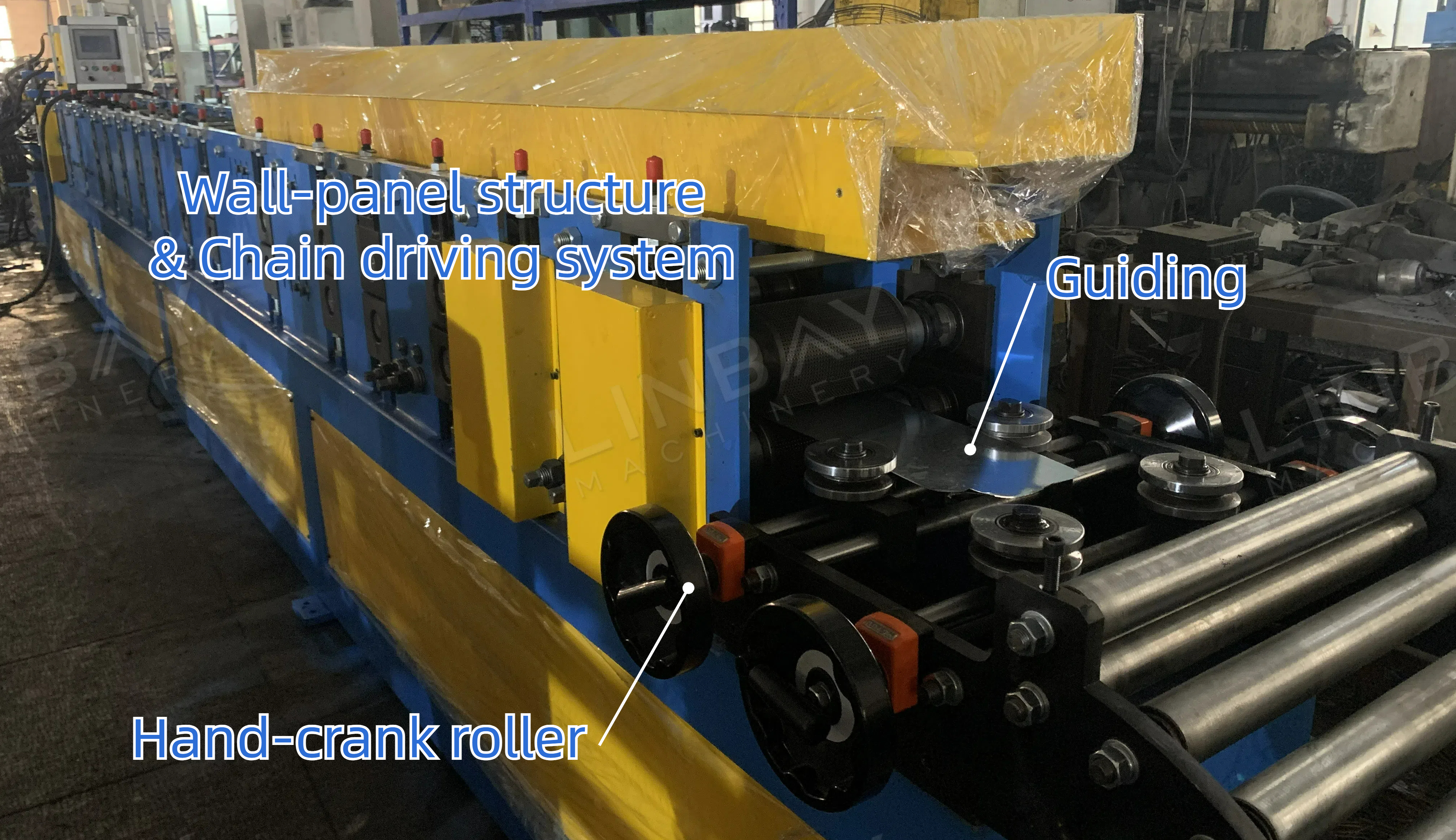

Mochine oa ho etsa 5.Roll: Sebopeho sa marako a marako

6.Sistimi ea ho khanna: Mokhoa oa ho khanna oa ketane

7.Ho phunya le tsamaiso ea ho itšeha: Matla a Hydraulic. Mofuta o fofang, moqolo oa pele ha o emise ha o seha.

8.PLC cabinet: Siemens tsamaiso. Mofuta o nkehang habonolo.

Mechini ea 'nete ea linyeoe

1.Decoiler*1

2.Roll forming machine*1

3.Mochini o fofang oa hydraulic punch*1

4.Mochini oa ho itšeha o fofang*1

5.Ka ntle ho tafole*2

6.PLC taolo ea khabinete*1

7.Seteishene sa Hydraulic*1

8.Lebokose la likarolo tsa polokelo (Mahala)*1

Boholo ba setshelo: 1x20GP

Taba ea 'nete-Tlhaloso

Manual Decoiler

●Ka lebaka la bosesane ba profil ea stud 0.4-0.8mm, decoiler ea letsoho e ka fihlela litlhoko tse sa phutholohang.

●E sa sebetseng hantle: Leha ho le joalo, ha e na matla a eona 'me e itšetlehile ka mochine o etsang roll ho hula khoele ea tšepe.

●E hloka thuso ea matsoho: Tensioning ea mandrel e boetse e etsoa ka letsoho, e bakang ts'ebetso e tlaase le ho phethahatsa litlhoko tsa motheo tsa ho koala feela.

Mofuta oa Boikhethelo oa Decoiler: Decoiler ea Motorized

● E tsamaisoa ke enjene, e eketsa bokhoni ba ho theola 'me e fokotsa tlhokahalo ea ho kenella ka letsoho le litšenyehelo tsa mosebetsi.

Decoiler ea boikhethelo: Hydraulic decoiler

● Foreimi e tsitsitseng le e tiileng:E sebelisetsoa ho kenya likhoele tsa tšepe. Decoiler e tsamaisoang ke hydraulic e etsa bonnete ba ts'ebetso e nepahetseng le e sireletsehileng ea ho fepa moleng oa tlhahiso.

● Sesebelisoa sa ho atolosa:Mandrel kapa arbor e khannoang ka li-hydraulic ea atoloha le likonteraka tsa ho kopanya likhoele tsa tšepe tse nang le bophara ba ka hare ba 490-510mm.(kapa e hlophisitsoeng), ho tiisa likhoele hore li theohe boreleli.

● Tobetsa-letsoho:Mochine oa hydraulic-letsoho le tšoara khoele sebakeng, ho thibela ho lokolloa ka tšohanyetso ha khatello ea maikutlo e ka 'nang ea ntša basebetsi kotsi.

● Coil retainer:E khomaretsoe ka thata ho li-blades tsa mandrel ka li-screws le linate, e thibela khoele hore e se ke ea thella ho tloha sefateng. E ka kenngoa habonolo le ho tlosoa.

● Sistimi ea ho laola:E na le PLC le phanele ea taolo, e nang le konopo ea ho emisa ts'ohanyetso bakeng sa polokeho e ntlafalitsoeng.

Tataiso

● Mosebetsi oa mantlha:Ho tataisa khoele ea tšepe haufi le setsi sa mochini, ho thibela ho se tsamaisane ho ka bakang ho sotha, ho kobeha, li-burrs le litaba tse fapaneng sehlahisoa se felileng.

● Lisebelisoa tse tataisang:Lirolara tse ngata tse tataisang li teng monyako le ka har'a mochini o etsang moqolo ho ntlafatsa phello ea tataiso.

● Tlhokomelo:Kamehla lekanya bohole ba lisebelisoa tse tataisang, haholo kamora lipalangoang le nakong ea ts'ebeliso ea nako e telele.

● Thomello esale pele:Rona, sehlopha sa Linbay re lekanya le ho rekota bophara bo tataisang bukeng ea mosebelisi bakeng sa teka-tekano ea bareki ha re e fumana.

● Bophara bo tataisang bo ka fetoloa hantle ka ho sebelisa rolara ea letsoho.

Foromo ea rollmochini o kenyang

● Litekanyo tse ngata li fumaneha: Mohala ona oa tlhahiso o ka fetola ka letsoho lintlha tsa ho etsa li-roller ho hlahisa mefuta e meraro e fapaneng ea li-studs. Re fana ka libuka, ho laela livideo, mehala ea video, le tataiso ea sebakeng sa marang-rang ho tsoa ho baenjiniere ho thusa basebetsi ba bareki ho ithuta ho fetola lirolara.

Tobetsa setšoantšo se ka tlase ho bona mokhoa oa ho fetola sebaka sa roller:

● Boemo ba Asymmetric:Ho fapana le li-profiles tse tloaelehileng, profil ena ea Montante construcción en seco e na le likarolo tse peli tse phahameng tsa asymmetric, tse hlokang moralo o nepahetseng haholoanyane oa lirolara tsa mochini.

● Tlhophiso ea moruo le e loketseng:E na le sebopeho sa marako-phanele le tsamaiso ea ho khanna ketane, e loketseng haholo ha khoele ea tšepe e le 0.4-0.8mm e teteaneng.

● Lirolara tse khabisang:Coil ea tšepe e feta har'a sete ea lirolara tse khabisang, e hatisa lipaterone tsa matheba sebakeng sa profil ho eketsa likhohlano le ho matlafatsa ho khomarela samente.

● Sekoahelo sa ketane:Liketane li koahetsoe ke lebokose la tšepe, ho netefatsa ts'ireletso ea basebetsi le ho sireletsa liketane ho tsoa tšenyo e bakoang ke likaroloana tse tsamaeang le moea.

● Lirolara:Chrome-plated le mocheso-pheko bakeng sa mafome le corrosion resistance, ho lelefatsa bophelo ba bona.

● Enjene e kholo:380V e tloaelehileng, 50Hz, 3Ph, e nang le mokhoa o ikhethileng o fumanehang.

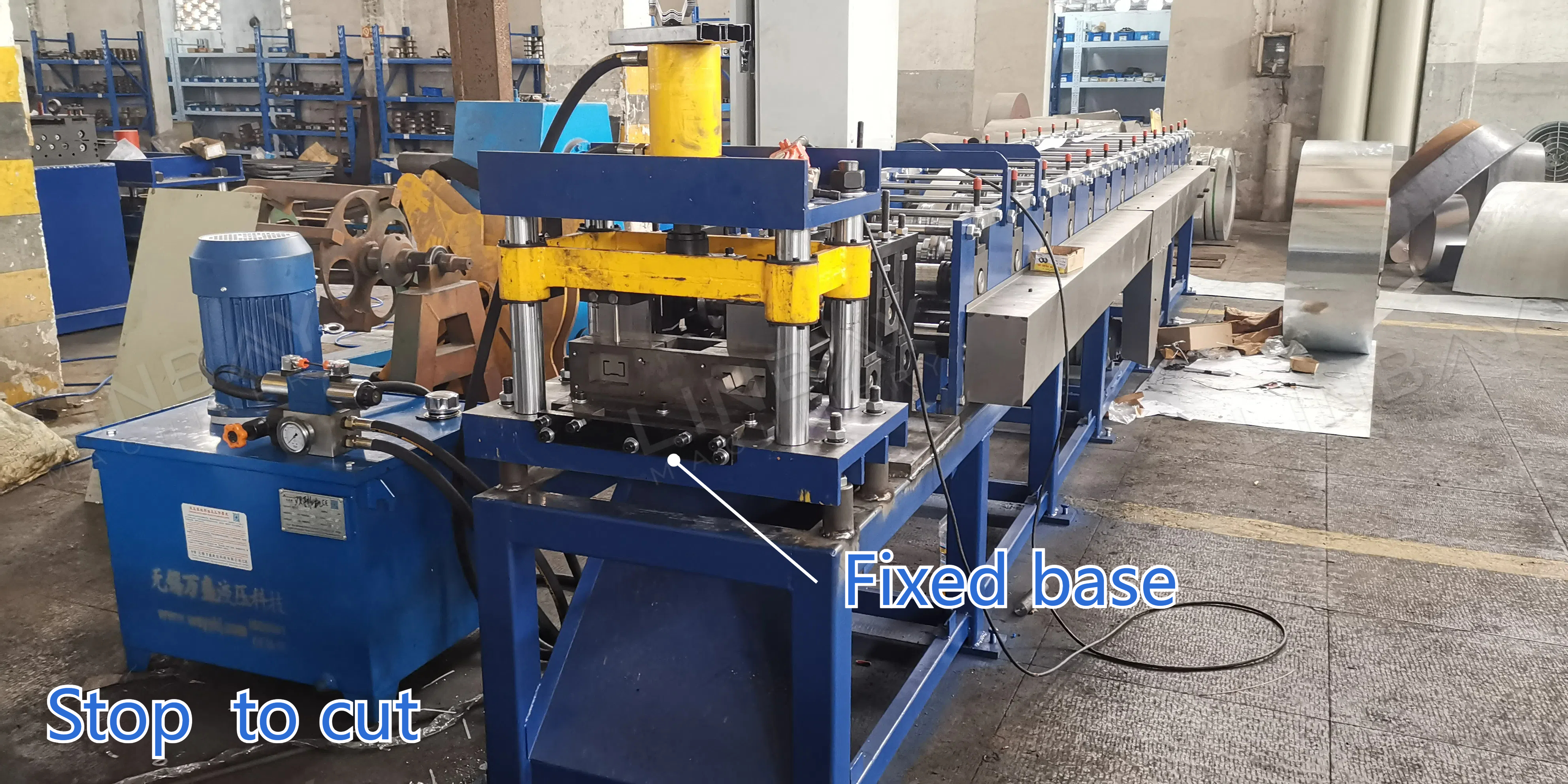

Flying hydraulic punch & Flying hydraulic cut

● Bokhoni bo phahameng:Mechine ea ho phunya le ea ho itšeha e arolelana motheo o le mong, e ba lumellang hore ba tsoele pele ka lebelo le tšoanang le la mochine oa ho etsa. Sena se boloka libaka tsa ho phunya le ho seha li batla li eme, ho nolofalletsa ts'ebetso e tsoelang pele ea mochini oa ho etsa 'me qetellong e ntlafatse katleho ea tlhahiso ka kakaretso.

● Moralo oa liteishene tse peli:Ho phunya le ho itšeha ho etsoa liteisheneng tse peli tse arohaneng tsa hydraulic, tse fanang ka maemo a fetohang haholoanyane. Ho phunya hlobo ho ka etsoa ho latela litšoantšo tsa bareki.

● Ho nepahala ha bolelele bo phahameng:Mamello ka har'a ± 1mm, e fihlelletsoeng ho sebelisoa encoder ho lekanya bolelele ba coil ea tšepe, ho e fetolela mats'oao a motlakase, le ho khutlisetsa data ena ho khabinete ea PLC. Basebetsi ba ka beha bolelele ba ho itšeha, bongata ba tlhahiso, le lebelo skrineng sa PLC.

Tharollo e Setlehileng ka Litšenyehelo ka Boikhethelo: Khaotsa ho Iphunya le ho Emisa ho Seha

Bakeng salitlhoko tse tlase tsa tlhahiso le likhakanyo tse fokolang tsa lichelete, litlhophiso tsa ho emisa le ho emisa ho seha li ka sebelisoa. Nakong ea ho phunya le ho itšeha, mochini oa ho etsa o tlameha ho ema hanyane ho amohela lits'ebetso tsena. Le hoja sena se fella ka katleho e tlaase, boleng ba ho phunya le ho itšeha bo lula bo le holimo.

1. Decoiler

2. Ho fepa

3.Ho phunya

4. Litomo tsa ho etsa roll

5. Mokhoa oa ho khanna

6. Mokhoa oa ho khaola

Ba bang

Tafole e kantle