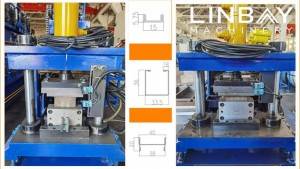

Perfil

Rolling shutter slats yog ib qho tseem ceeb ntawm cov dov shutters, nrog cov qauv tsim sib txawv nyiam nyob hauv ntau lub khw hauv cheeb tsam. Txias yob txoj kab sib sau yog ib qho kev xaiv zoo tshaj plaws rau kev tsim cov slats.

Pab pawg Linbay tuaj yeem muab cov kev daws teeb meem tsim nyog raws li peb cov kev paub dhau los, cov kev xav tau ntau lawm rau txhua qhov profile, thiab cov kev xav tau xuas nrig ntaus.

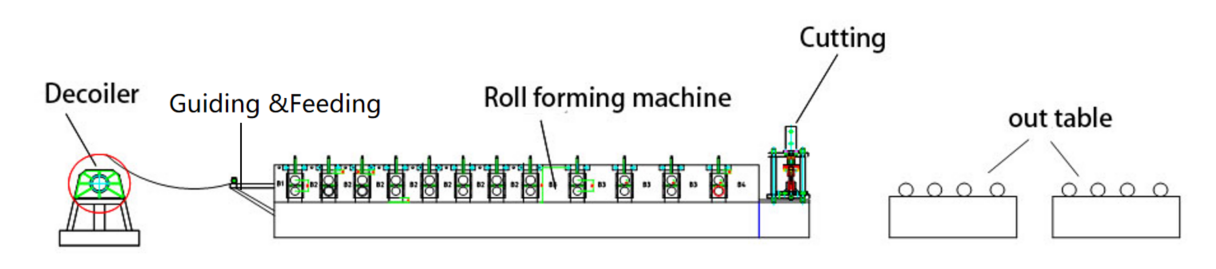

Cov ntaub ntawv tiag-Flow chart

Hydraulic decoiler--Kev taw qhia--Roll txoj kev tshuab--Hydraulic txiav tshuab--Out rooj

Cov ntaub ntawv tiag-Main Technical Parameters

1.Line ceev: 0-12m / min, adjustable

2. Cov khoom tsim nyog: Galvanized steel

3.Material thickness: 0.6-0.8mm

4.Roll forming tshuab: Cast-hlau qauv

5.Driving system: Chain tsav tsheb

6.Kev kaw lus: Hydraulic zog. Nres kom txiav, yob qub yuav tsum nres thaum txiav.

7.PLC txee: Siemens system.

Cov ntaub ntawv tiag-Machinery

1.Manual decoiler * 1

2. Roll forming tshuab * 1

3.Hydraulic tej tshuab * 1 (Txhua qhov dov shutter slat profile xav tau 1 cais cov hniav)

4.Out table*2

5.PLC tswj txee * 1

6.Hydraulic chaw nres tsheb * 1

7.Cov khoom seem lub thawv (Dawb) * 1

Cov ntaub ntawv tiag tiag-Kev piav qhia

Decoiler

● Cov menyuam shutter slats:Vim lawv me me thickness thiab dav,phau ntawv thiab motorizeddecoilers txaus kom ua tau raws li qhov yuav tsum tau ua.

● Phau ntawv version:Tsis-powered, cia siab rau lub zog ntawm txoj kev chais kom rub lub steel kauj rau pem hauv ntej. Nws muaj qis uncoiling efficiency thiab tsawg dua kev nyab xeeb. Mandrel expansion yog ua manually. Nws yog nqi-zoo tab sis tsis haum rau loj-scale nruam ntau lawm.

●Tsav version:Powered los ntawm lub cev muaj zog, nws ua rau kom uncoiling efficiency thiab txo qhov xav tau ntawm phau ntawv kev cuam tshuam, txuag nqi zog.

Yeem Decoiler Hom: Ob Lub Taub Hau Decoiler

● Ntau qhov dav:Ob lub taub hau decoiler tuaj yeem khaws cov hlau coils ntawm qhov dav sib txawv, haum rau ob kab sib sau tshuab.

● Kev ua haujlwm tsis tu ncua:Thaum ib lub taub hau uncoiling, lwm tus tuaj yeem thauj khoom thiab npaj lub kauj tshiab. Thaum siv ib lub kauj, lub decoiler tuaj yeem tig 180 degrees rau

Kev taw qhia

● Lub luag haujlwm tseem ceeb:Txhawm rau ua kom cov hlau kauj nrog lub tshuab qhov nruab nrab, tiv thaiv kev tsis sib haum xeeb uas tuaj yeem ua rau sib tw, khoov, burrs, thiab qhov loj me ntawm cov khoom tiav.

● Cov cuab yeej taw qhia:Ntau yam kev taw qhia ntawm cov khoom noj nkag thiab hauv lub tshuab yob txoj kev txhim kho cov kev taw qhia.

● Kev Kho Mob:Tsis tu ncua calibrate qhov kev ncua deb ntawm cov kev taw qhia, tshwj xeeb tshaj yog tom qab thauj thiab thaum lub sij hawm siv mus sij hawm ntev.

● Kev xa khoom ua ntej:Pab pawg Linbay ntsuas thiab sau cov lus qhia dav hauv phau ntawv siv rau cov neeg siv khoom ntsuas thaum tau txais.

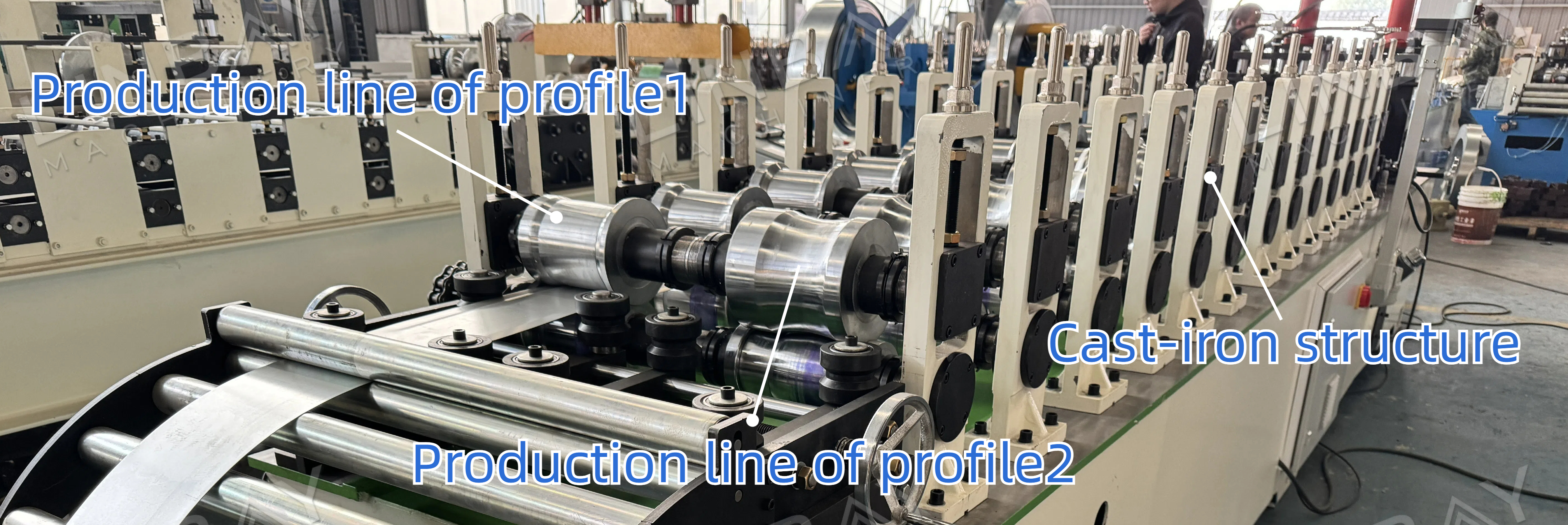

Roll forming tshuab

● Ntau yam duab:Cov txheej txheem ob kab tuaj yeem tuav cov dov shutter slats ntawm ob daim duab sib txawv, txo cov nqi tshuab thiab qhov chaw rau cov neeg siv khoom.

●Nco tseg:Ob txoj kab ntau lawm tsis tuaj yeem khiav ib txhij. Rau siab ntau lawm xav tau ntawm ob leeg profiles, nws yog pom zoo kom siv ob cais ntau lawm kab.

●Qauv:Features ib tug cam khwb cia hlau sawv ntsug thiab saw tsav system.

●Chain npog:Cov saw hlau muaj kev tiv thaiv los ntawm cov hlau mesh, ua kom cov neeg ua haujlwm muaj kev nyab xeeb thiab tiv thaiv cov khib nyiab los ntawm kev puas tsuaj rau cov saw hlau.

●Rollers:Chrome-plated thiab kub-kho rau xeb thiab corrosion kuj, ncua lawv lifespan.

●Main lub cev muaj zog:Standard 380V, 50Hz, 3-theem, nrog rau customization muaj.

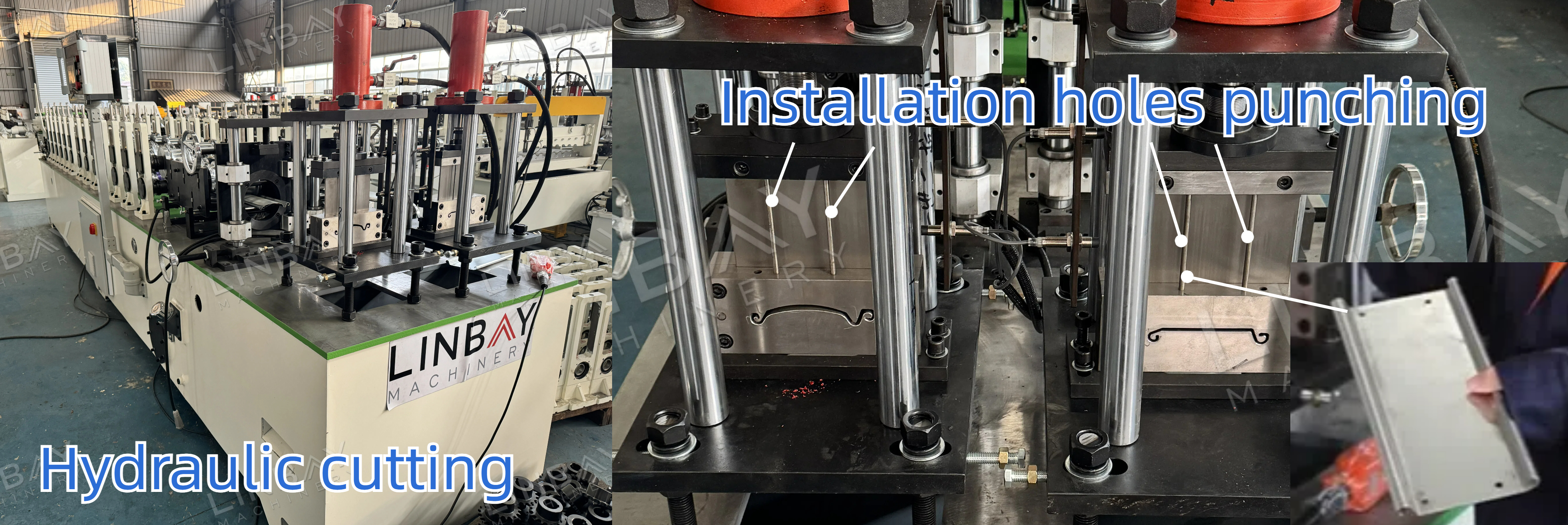

Hydraulic txiav tshuab

●Precision-engineered hniav:Tsim los ua kom haum rau cov dov shutter slat specifications, kom ntseeg tau tias du, deformation-dawb, thiab burr-dawb txiav npoo.

●High txiav ntev raug:Kev kam rau siab nyob rau hauv ± 1 hli, ua tiav siv lub encoder los ntsuas cov hlau kauj ua ntej ntev, hloov mus rau cov teeb liab hluav taws xob, thiab pub cov ntaub ntawv no rov qab rau PLC txee. Cov neeg ua haujlwm tuaj yeem teem sijhawm txiav ntev, ntau lawm, thiab nrawm ntawm PLC npo.

Cov cuab yeej xaiv tau: Installation qhov xuas nrig ntaus

●Qhov kawg qhov:Txhua qhov kawg ntawm dov shutter slats muaj ob lub qhov sib txuam nrog cov mounting fasteners. Cov qhov no kuj tuaj yeem ua rau ntawm txoj kab sib sau, txo cov sijhawm ntawm phau ntawv drilling thiab cov nqi.

●Punching thiab txiav:Ob lub punches nyob ua ntej thiab tom qab txiav cov hniav, sib koom ib qho chaw nres tsheb hydraulic kom ua rau tib lub sijhawm txiav thiab xuas nrig ntaus.

●Customizable xuas nrig ntaus:Qhov loj thiab qhov deb ntawm ntug tuaj yeem kho tau.

Cov cuab yeej xaiv tau: Standalone hydraulic punch tshuab

●Haum rau kev nruam los yog tuab xuas nrig ntaus:Zoo tagnrho rau high-frequency punching xav tau.

●Kev sib koom ua haujlwm zoo:Thaum qhov kev thov rau cov punched dov shutters qis dua rau cov uas tsis yog punched shutters, cais cov xuas nrig ntaus thiab tsim cov txheej txheem rau hauv ob txoj kab ntau lawm tuaj yeem txhim kho kev ua tau zoo tag nrho.

●Kev cai punching tuag:Yog tias tus neeg siv khoom muaj cov punching tuag tshiab tom qab tau txais, peb tuaj yeem hloov kho tshiab tuag nyob rau hauv thawj hydraulic punch tshuab pub dav dav.

Kev sim

● Peb cov engineers yuav calibrate txhua theem ntawm ob-kab tshuab ua ntej ua zaub mov xa tuaj kom ntseeg tau tias kev tsim khoom tuaj yeem pib sai thaum tau txais.

● Cov dov shutters uas tsim tawm yuav muab piv rau 1: 1 nrog cov duab kos.

● Peb kuj tseem yuav txiav kwv yees li 2 meters ntawm qhov profile thiab sib sau ua ke 3-4 daim los kuaj xyuas tias cov shutters haum nruj tsis loosening thiab dov nrog qhov sib txawv uas tsim nyog.

1. Decoiler

2. Pub noj

3. Punching

4. Roll forming stands

5. Tsav tsheb

6. Txiav qhov system

Lwm tus

Tawm rooj

1-300x168.jpg)