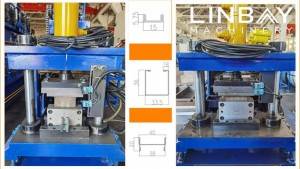

Perfil

Ii-rolling shutter slats yinxalenye ebalulekileyo yezivalo eziqengqelekayo, ezineprofayile zoyilo ezahlukeneyo ezikhethwa kwiimarike ezahlukeneyo zengingqi. Imigca yokwenza i-Cold roll yinto eqhelekileyo kunye neyobuchule yokukhetha ukuvelisa ezi slats.

IQela leLinbay linokubonelela ngezisombululo ezifanelekileyo zokuvelisa ngokusekelwe kumava ethu, iimfuno zokuvelisa kwiprofayili nganye, kunye neemfuno zokubetha.

Ityala lokwenyani-Ukuqukuqela itshati

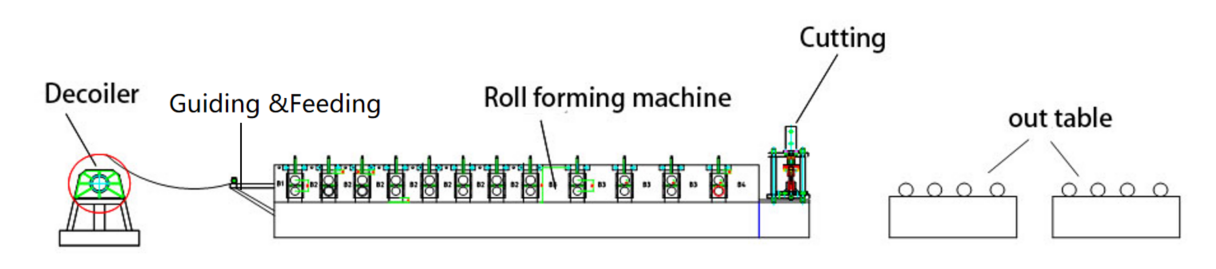

I-Hydraulic decoiler--Isikhokelo--Umatshini wokwenza i-Haydraulic-Umatshini wokusika we-Hydraulic--Itafile engaphandle

Imeko yokwenyani-Iiparamitha zobuGcisa eziPhambili

1.Isantya somgca: 0-12m / min, ukulungiswa

2.Izinto ezifanelekileyo:Intsimbi yegalvanized

3.Ubukhulu bezinto: 0.6-0.8mm

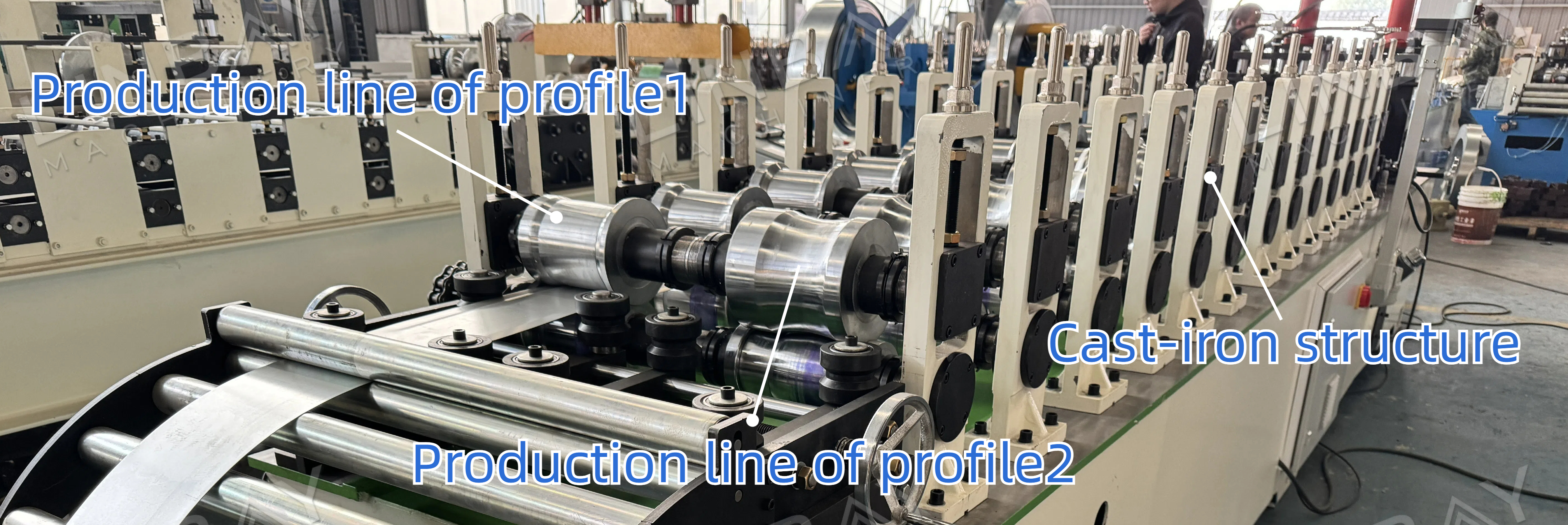

Umatshini wokwenza i-4.Roll: Isakhiwo se-Cast-iron

I-5.Inkqubo yokuqhuba: Inkqubo yokuqhuba ikhonkco

I-6.Inkqubo yokusika: Amandla e-hydraulic. Yeka ukusika, ukuqengqeleka kwangaphambili kufuna ukuyeka xa usika.

Ikhabhinethi ye-7.PLC: inkqubo ye-Siemens.

Ityala lokwenyani-oomatshini

1.I-decoiler yokwenziwa ngesandla*1

2.Umatshini wokwenza umqulu*1

3.Umatshini wokusika we-Hydraulic * 1 (Iprofayili nganye ye-rolling shutter slat ifuna i-1 i-blade yokusika eyahlukileyo)

4.Ngaphandle kwetafile*2

5.PLC iKhabhinethi yolawulo*1

6.Isikhululo samanzi*1

7.Ibhokisi yezahlulo ezisecaleni(Mahala)*1

Imeko yokwenyani-Inkcazo

I-Decoiler

● Izilayiti ezizirola:Ngenxa yobukhulu bayo obuncinci kunye nobubanzi,manual kunye nemotoii-decoilers zanele ukuhlangabezana neemfuno zokukhulula.

● Inguqulelo eyenziwe ngesandla:I-Non-powered, ixhomekeke kumandla okwenziwa kwee-rollers ukutsala i-coil yensimbi phambili. Inokusebenza okuphantsi kokukhulula kunye nokhuseleko olusezantsi kancinane. Ukwandiswa kweMandrel kwenziwa ngesandla. Ixabisa kakhulu kodwa ayifanelekanga kwimveliso enkulu eqhubekayo.

●Imoto inguqulelo:Inikwe amandla yimoto, inyusa ukusebenza kakuhle kokungaqhawukiyo kwaye inciphisa imfuno yokungenelela ngesandla, ukonga iindleko zabasebenzi.

Uhlobo lwe-Decoiler oluKhethekileyo: I-Decoiler enentloko ephindwe kabini

● Ububanzi obuguquguqukayo:I-decoiler enentloko ephindwe kabini inokugcina iikhoyili zetsimbi ezinobubanzi obuhlukeneyo, ezifanelekileyo kumatshini wokwenza imiqolo emibini.

● Umsebenzi oqhubekayo:Ngelixa intloko enye ikhulula, enye inokulayisha kwaye ilungiselela ikhoyili entsha. Xa ikhoyili enye isetyenziswe phezulu, i-decoiler inokujikeleza i-180 degrees ukuya

Ukukhokela

● Umsebenzi ophambili:Ukulungelelanisa i-coil yensimbi kunye ne-centerline yomatshini, ukuthintela ukungahambi kakuhle okunokubangela ukujija, ukugoba, i-burrs, kunye nemiba yobukhulu kwimveliso egqityiweyo.

● Izixhobo zokukhokela:Izixhobo ezininzi ezikhokelayo kwindawo yokungenisa ukutya kunye nangaphakathi kumatshini wokwenza umqulu wongeza isiphumo esikhokelayo.

● Ugcino:Ukulinganisa rhoqo umgama wezixhobo ezikhokelayo, ngakumbi emva kokuthutha kunye nexesha elide lokusetyenziswa.

● Ukuthunyelwa kwangaphambili:Iqela leLinbay lilinganisa kwaye lirekhoda ububanzi besikhokelo kwincwadana yomsebenzisi yokulinganisa umthengi xa efunyenwe.

Umatshini wokwenza umqulu

● Iimilo eziguquguqukayo:Ubume bemiqolo ephindwe kabini bunokusingatha i-rolling shutter slats yeemilo ezimbini ezahlukeneyo, ukunciphisa iindleko zomatshini kunye nendawo kubathengi.

●Phawula:Imigca emibini yemveliso ayikwazi ukusebenza ngaxeshanye. Kwiimfuno eziphezulu zemveliso yazo zombini iiprofayili, kucetyiswa ukuba kusetyenziswe imigca emibini eyahlukeneyo yokuvelisa.

●Ulwakhiwo:Ifaka i-cast-iron stand kunye ne-chain drive system.

●Ikhonkco lekhonkco:Amatyathanga akhuselwe nge-mesh yensimbi, eqinisekisa ukhuseleko lwabasebenzi kunye nokuthintela i-debris ekonakaliseni amatyathanga.

●IiRola:I-Chrome-plated kunye nokushisa-inyangelwe umhlwa kunye nokuxhathisa ukubola, ukwandisa ubomi babo.

●Injini engundoqo:Standard 380V, 50Hz, 3-isigaba, kunye ngokwezifiso ezikhoyo.

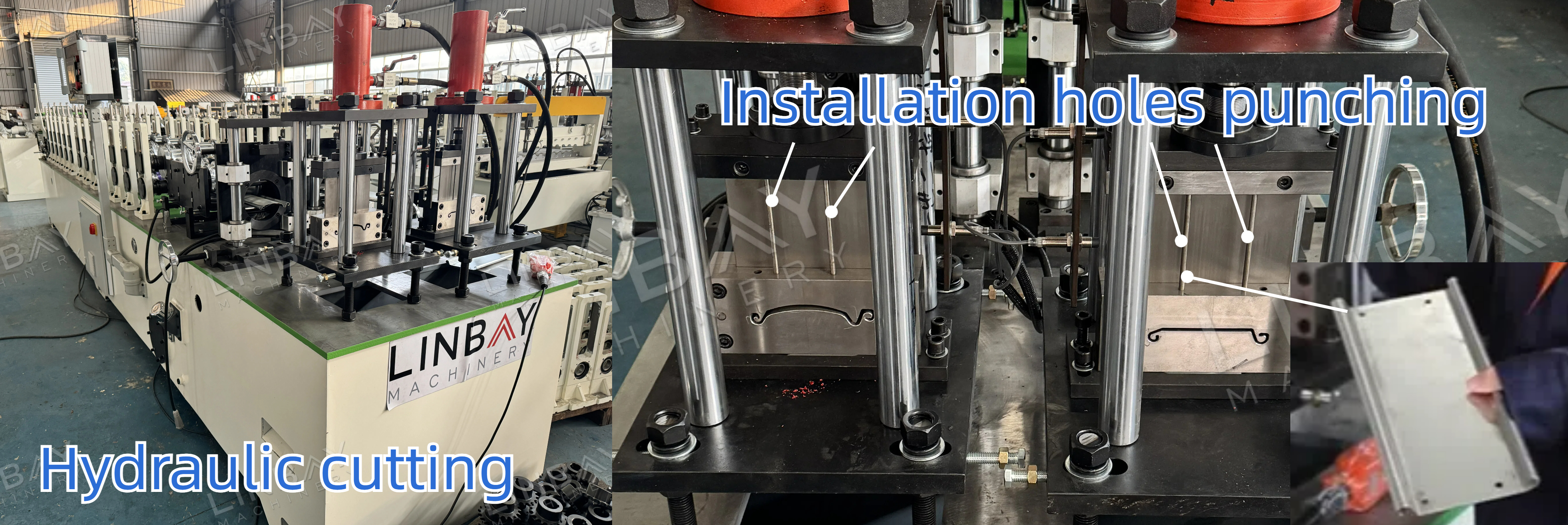

Umatshini wokusika we-hydraulic

●Iincakuba ezenziwe ngobunjineli ngokuchanekileyo:Idizayinelwe ukuhambelana neenkcukacha ze-slat yesivalo esiqengqelekayo, iqinisekisa ukuba igudile, ingenakuguqulwa, kunye nemiphetho yokusika engenaburr.

●Ukuchaneka kobude obuphezulu bokusika:Ukunyamezela ngaphakathi kwe-± 1mm, kuphunyezwe ngokusebenzisa i-encoder ukulinganisa ubude be-coil yentsimbi, ukuyiguqulela kwiimpawu zombane, kunye nokondla le datha kwikhabhinethi ye-PLC. Abasebenzi banokuseta ubude bokusika, ubungakanani bemveliso, kunye nesantya kwiscreen sePLC.

Isixhobo ozikhethelayo: Ufakelo imingxunya ngenqindi

●Ukuphelisa imingxunya:Isiphelo ngasinye se-rolling shutter slats sinemingxuma emibini ehambelana ne-fasteners yokunyuka. Le mingxuma ingenziwa kwakhona kumgca wokwenza, ukunciphisa ixesha lokugaya ngesandla kunye neendleko.

●Ukubetha kunye nokusika:Iipuntshi ezimbini zifumaneka ngaphambi nangemva kwee-blades zokusika, ukwabelana ngesikhululo esisodwa se-hydraulic ukuze sikwazi ukusika kunye nokubetha ngaxeshanye.

●Ukubetha okulungiselelweyo:Ubungakanani bomngxuma kunye nomgama ukusuka kumda unokwenziwa ngokwezifiso.

Isixhobo esinokuzikhethela: Umatshini we-Standalone hydraulic punch

●Ifanelekile ukubetha okuzingileyo okanye okuxineneyo:Ilungele iimfuno zokubethelwa rhoqo.

●Ulungelelwaniso lwemveliso olusebenzayo:Xa imfuno ye-punched rolling shutters ingaphantsi kune-non-punched shutters, ukwahlula ukubethelwa kunye nokwenza iinkqubo zibe yimigca emibini yemveliso ezimeleyo kunokwandisa ukusebenza kakuhle ngokubanzi.

●Ukubethelwa ngokwesiko kuyafa:Ukuba umthengi uneendlela ezintsha zokufa emva kokuba efunyenwe, sinokwenza ngokwezifiso ukufa okutsha ngaphakathi kobubanzi bokutya komatshini we-hydraulic punch.

Uvavanyo

● Iinjineli zethu ziya kulinganisa isigaba ngasinye somatshini we-double-row ngaphambi kokuthunyelwa ukuqinisekisa ukuba imveliso inokuqalisa ngokukhawuleza xa ifunyenwe.

● Ii-shutter eziveliswayo ziya kuthelekiswa ne-1: 1 kunye nemizobo.

● Kwakhona siya kusika malunga neemitha ezi-2 zeprofayili kwaye sihlanganise iziqwenga ezi-3-4 ukuvavanya ukuba izivalo zihambelana ngokuqinileyo ngaphandle kokukhulula kunye nokuqengqeleka kunye nesithuba esifanelekileyo.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile

1-300x168.jpg)