I-Perfil

Le mikhiqizo yodonga lwensimbi isetshenziswa ezinhlelweni ezahlukahlukene, njengezindonga ezithwala umthwalo, izindonga zamakhethini, izixhumi zaphansi, nezinsimbi zophahla.

Izikhonkwane, amathrekhi, ama-omega, namanye amaphrofayli wegeji yokukhanya ngokuvamile akhiqizwa imigqa eyakha imigqa ebandayo. Ubukhulu bephrofayili namaphethini wokubhoboza kungenziwa ngezifiso.

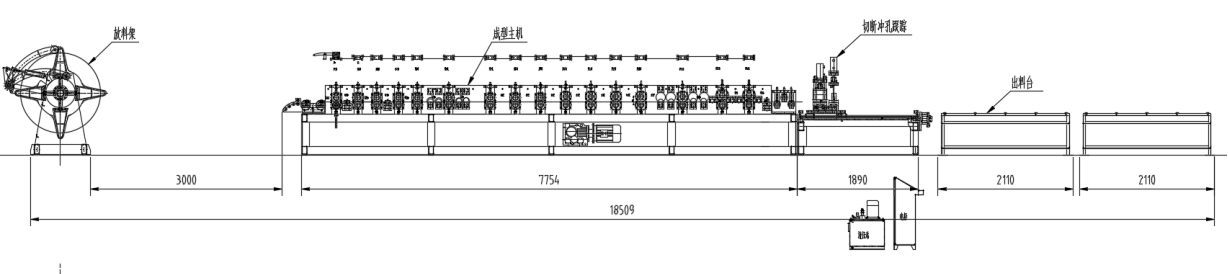

Ishadi lokugeleza kwekesi langempela

I-Decoiler--Guiding--Roll former--Flying hydraulic punch--Flying hydraulic cut--Out table

Ikesi langempela-Amapharamitha Obuchwepheshe Abalulekile

1.Ijubane lomugqa: 0-15m/min ngokubhoboza, kulungiswa

2.Isivinini sokwenza: 0-40m/min

3.Impahla efanelekile:Insimbi enama-galvanized

4.Material ukujiya: 0.4-0.8mm

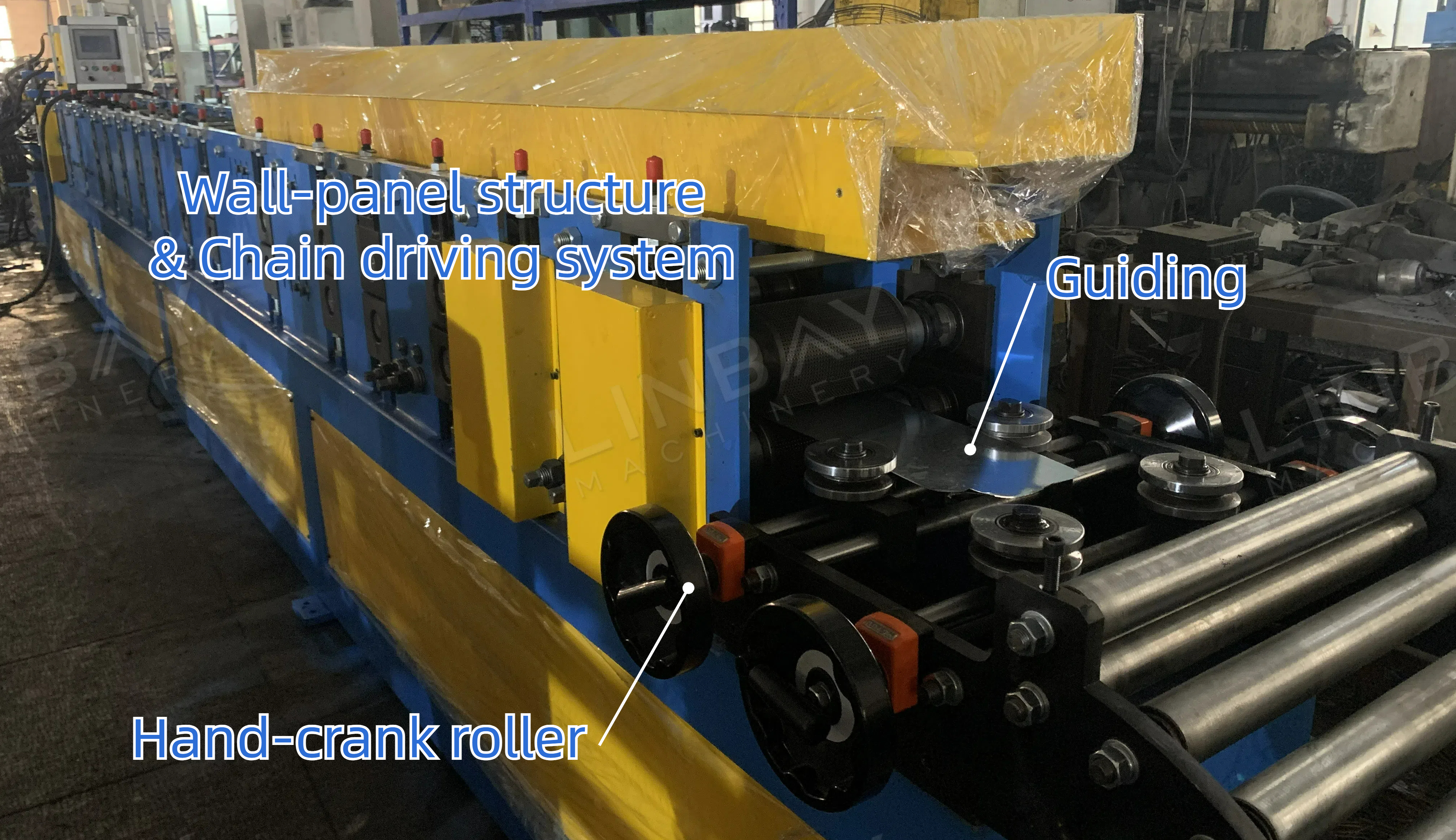

5.Umshini wokwenza umqulu: Isakhiwo sephaneli yodonga

I-6.Isistimu yokushayela: Uhlelo lokushayela lwe-chain

I-7.Punching kanye nohlelo lokusika: Amandla we-hydraulic. Uhlobo olundizayo, umqulu wangaphambili awumi lapho usikwa.

Ikhabhinethi ye-8.PLC: Uhlelo lwe-Siemens. Uhlobo oluphathekayo.

Ikesi langempela-Imishini

1.I-Decoiler*1

2.Umshini wokwenza umqulu*1

3.Umshini wokubhoboza we-hydraulic ondizayo*1

4.Umshini wokusika ondizayo*1

5.Ithebula elingaphandle*2

6.PLC control cabinet*1

7.Isiteshi samanzi*1

8.Ibhokisi lezingxenye eziyisipele(Mahhala)*1

Usayizi wesiqukathi: 1x20GP

Ikesi langempela-Incazelo

I-Decoiler Manual

●Ngenxa yobuncane bephrofayela ye-stud engu-0.4-0.8mm, i-decoiler eyenziwa ngesandla ingahlangabezana nezidingo zokuqaqa.

●Ayisebenzi kahle: Nokho, ayinawo amandla ayo futhi incike emshinini wokwenza umqulu ukudonsa ikhoyili yensimbi.

●Idinga usizo lwezandla: I-mandrel tensioning nayo yenziwa ngesandla, okuholela ekusebenzeni kahle okuphansi nokugcwalisa kuphela izidingo eziyisisekelo zokuqaqa.

Uhlobo lwe-Decoiler olungakhethwa: I-Motorized Decoiler

● Inikwe amandla yinjini, inyusa ukusebenza kahle kokuqaqa futhi inciphisa isidingo sokungenelela okwenziwa ngesandla kanye nezindleko zomsebenzi.

I-decoiler yokuzikhethela: I-Hydraulic decoiler

● Uzimele ozinzile noqinile:Isetshenziselwa ukulayisha amakhoyili ensimbi. I-decoiler ene-hydraulic powered iqinisekisa inqubo yokudla esebenza kahle futhi ephephile emgqeni wokukhiqiza.

● Idivayisi yokunweba eyinhloko:I-mandrel eqhutshwa nge-hydraulic noma i-arbor iyanwebeka futhi ivumelane ukuze ilingane namakhoyili ensimbi anobubanzi bangaphakathi obungu-490-510mm.(noma ngokwezifiso), ukuvikela amakhoyili ukuze aqaqeke bushelelezi.

● Cindezela-ingalo:I-hydraulic press-ingalo ibamba ikhoyili endaweni, ukuvimbela ukukhululwa kungazelelwe kokucindezeleka kwangaphakathi okungalimaza izisebenzi.

● Ikhoyili egcina ikhoyili:Inamathele ngokuqinile kuma-mandrel blades ngezikulufo namantongomane, ivimbela ikhoyili ukuthi ingasheleli ku-shaft. Ingafakwa kalula futhi isuswe.

● Isistimu yokulawula:Ifakwe i-PLC kanye nephaneli yokulawula, enenkinobho yokumisa izimo eziphuthumayo ukuze kuthuthukiswe ukuphepha.

Ukuqondisa

● Umsebenzi oyinhloko:Ukuze uqondise ikhoyili yensimbi phakathi nendawo emaphakathi yomshini, ukuvimbela ukungahambi kahle okungase kubangele ukusonteka, ukugoba, ama-burrs, nezinkinga zobukhulu kumkhiqizo oqediwe.

● Amadivayisi aqondisayo:Amarola amaningi aqondisayo atholakala emnyango nangaphakathi komshini wokwenza umqulu ukuze kuthuthukiswe umphumela oqondisayo.

● Ukunakekela:Linganisa njalo ibanga lemishini eqondisayo, ikakhulukazi ngemva kokuthutha kanye naphakathi kokusetshenziswa kwesikhathi eside.

● Ukuthunyelwa ngaphambilini:Thina, ithimba lase-Linbay silinganisa futhi sirekhoda ububanzi obuyisiqondiso kumanuwali yomsebenzisi ukuze kulinganiswe iklayenti lapho sithola.

● Ububanzi besiqondiso bungalungiswa kahle kusetshenziswa irola ye-hand-crank.

Roll ifomuumshini

● Ubukhulu obuningi buyatholakala: Lo mugqa wokukhiqiza ungalungisa mathupha amaphoyinti okwakheka kumarola ukuze ukhiqize osayizi abathathu abahlukene beziko. Sihlinzeka ngamamanyuwali, ukugunyaza amavidiyo, amakholi wevidiyo, neziqondiso ezikusayithi ezivela konjiniyela ukuze sisize abasebenzi bamakhasimende bafunde ukushintsha amarola.

Chofoza isithombe esingezansi ukuze ubone ukuthi ungasishintsha kanjani isikhala serola:

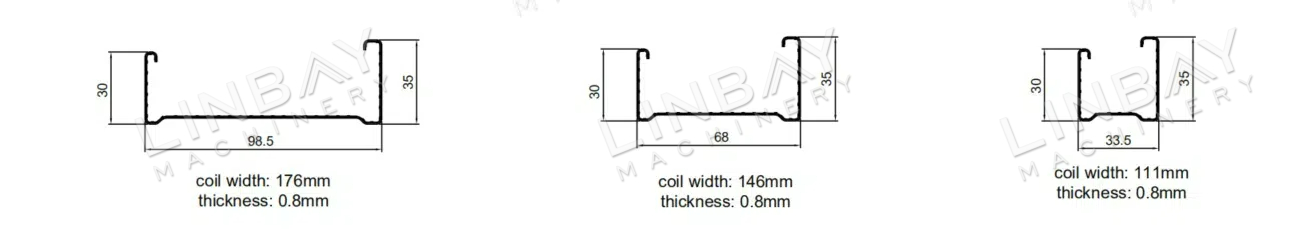

● Iphrofayela ye-Asymmetrical:Ngokungafani namaphrofayili e-stud avamile, le phrofayela ye-Montante construcción en seco ineziphetho ezimbili eziphakeme ezi-asymmetrical, ezidinga ukuklanywa okunembe kakhudlwana kwamarola omshini okwenza.

● Ukucushwa kwezomnotho nokufanelekile:Ifaka isakhiwo sephaneli yodonga kanye nesistimu yokushayela ngamaketango, efanelekile uma ikhoyili yensimbi ingu-0.4-0.8mm ubukhulu.

● Amarola agqamile:Ikhoyili yensimbi idlula kusethi yamarola agqamile, igxilisa amaphethini wamachashazi endaweni yephrofayili ukuze kwandiswe ukungqubuzana nokuthuthukisa ukunamathela kukasimende.

● Ikhava yochungechunge:Amaketanga ambozwe ibhokisi lensimbi, eliqinisekisa ukuphepha kwezisebenzi nokuvikela amaketanga emonakalweni obangelwa izinhlayiya ezihamba emoyeni.

● Amarola:Kufakwe i-Chrome-plated futhi kufakwe ukushisa ukuze kuvikeleke ukugqwala nokugqwala, kunwebe ubude bazo bempilo.

● Injini eyinhloko:I-380V ejwayelekile, i-50Hz, i-3Ph, nokwenza ngokwezifiso kuyatholakala.

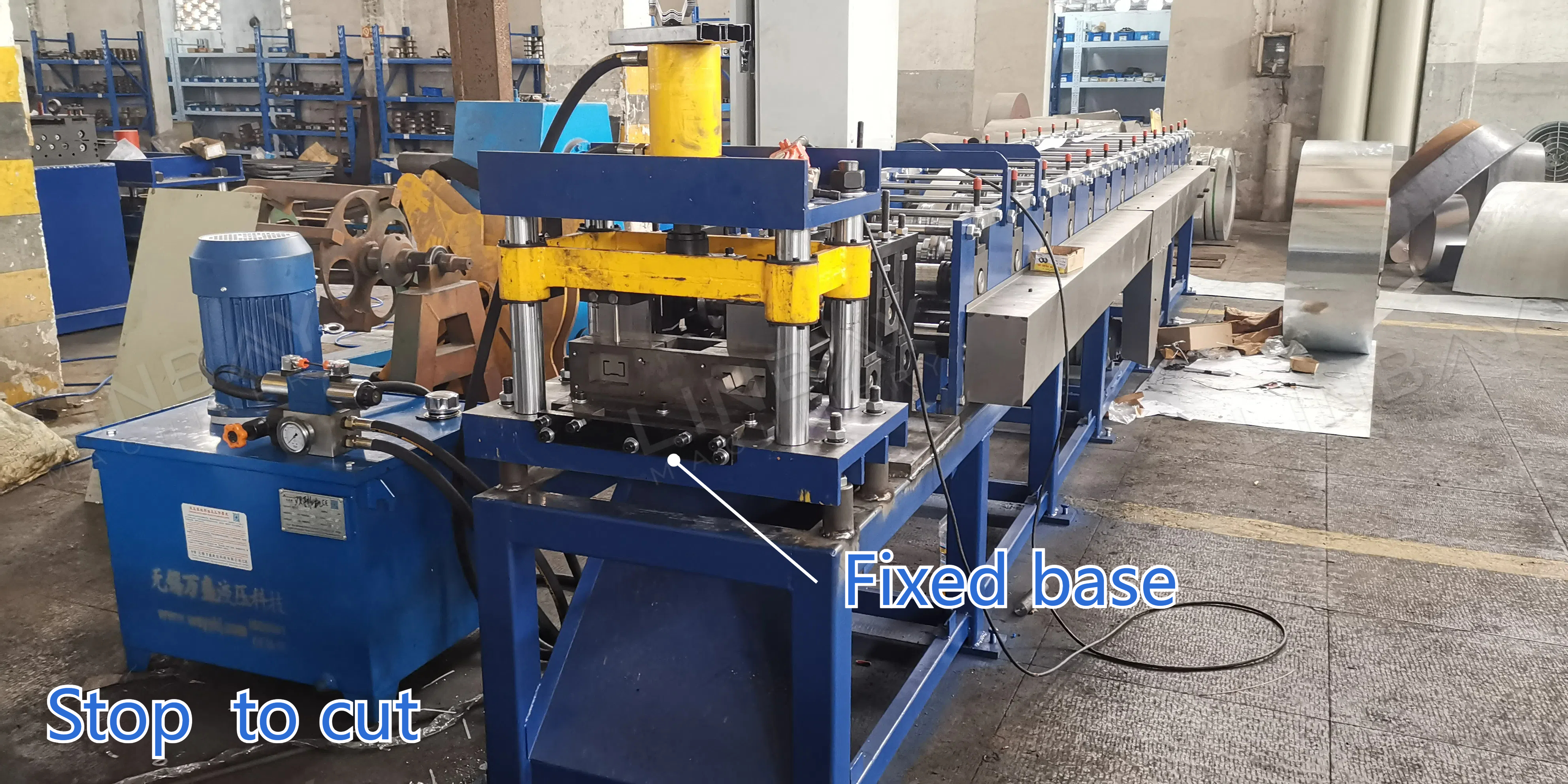

Flying hydraulic punch & Flying hydraulic cut

● Ukusebenza okuphezulu:Imishini yokubhoboza nokusika ihlanganyela isisekelo esisodwa, esibavumela ukuba baqhubekele phambili ngesivinini esifanayo nomshini wokwenza. Lokhu kugcina izindawo zokubhoboza nokusika zimile, kuvumela ukusebenza okuqhubekayo komshini wokwakha futhi ekugcineni kuthuthukisa ukusebenza kahle kokukhiqiza kukonke.

● Idizayini yeziteshi ezimbili:Ukubhoboza nokusika kwenziwa eziteshini ezimbili ezihlukene zama-hydraulic, okunikeza ukuguquguquka okukhulu. Ukubhoboza isikhunta kungenziwa ngokwezifiso ngokusho kwemidwebo yamakhasimende.

● Ukunemba kobude bokusika okuphezulu:Ukubekezelela phakathi kuka-±1mm, kufinyelelwe kusetshenziswa isifaki khodi ukulinganisa ubude bekhoyili yensimbi, ukuyiguqulela kumasignali kagesi, kanye nokubuyisela le datha kukhabhinethi ye-PLC. Izisebenzi zingasetha ubude bokusika, inani lokukhiqiza, nesivinini esikrinini se-PLC.

Isixazululo Esisebenzayo Esingabizi Ngokuzithandela: Yeka Ukubhoboza kanye Nokumisa Ukusika

Ngobaizidingo zokukhiqiza eziphansi kanye nesabelomali esilinganiselwe, ukumiswa kokumisa nokuyeka ukusika kungasetshenziswa. Ngesikhathi sokubhoboza nokusika, umshini wokwakha kufanele ume kancane ukuze uvumelane nalezi zinqubo. Nakuba lokhu kubangela ukusebenza kahle okuphansi, izinga lokubhoboza nokusika lihlala liphezulu.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle