Keterangan

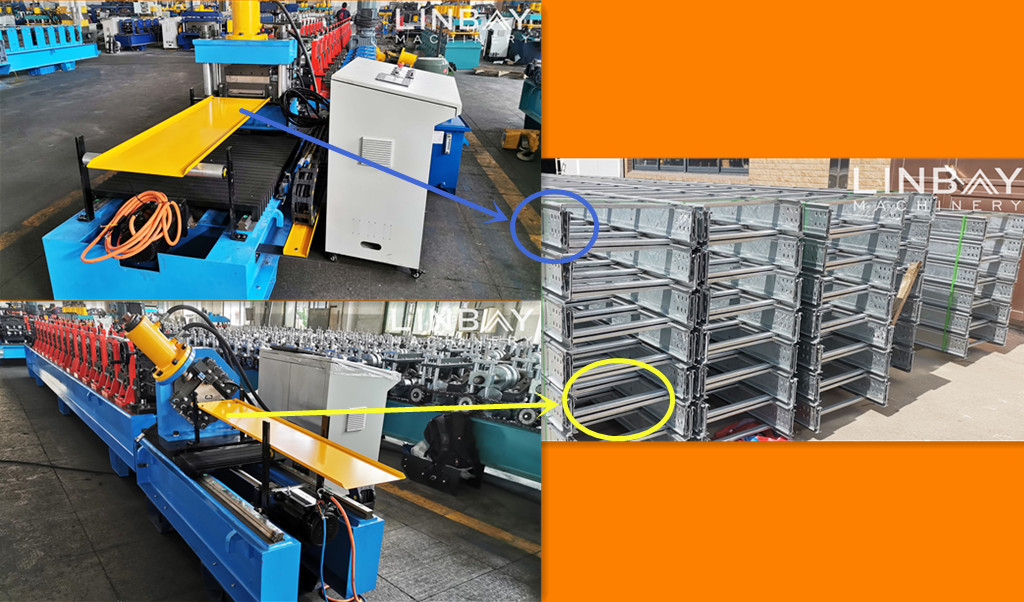

Linbay Machinery adalah ahli dalamcmesin pembuat gulungan baki yang mampuDanmesin pembentuk gulungan tangga kabelprodusen. Kami telah memproduksi berbagai macammesin pembentuk gulungan baki kabel dan tangga kabelDi sini Anda akan mengetahui detail mesin roll forming tangga kabel.

Tangga kabel normal memiliki dua bagian: dinding samping dan anak tangga, ketika Anda memiliki dua bagian ini dibuat dengan mesin roll forming, Anda memerlukan mesin las untuk membuat keduanya bersama-sama. Lebar tangga kabel adalah panjang anak tangga dan panjang tangga adalah panjang dinding samping. Jadi tangga kabel tidak memerlukan banyak investasi, hanya dua mesin roll forming, satu untuk tangga kabel dan satu untuk anak tangga, kemudian tukang las otomatis atau manual. Ini jauh lebih murah daripada mesin roll forming baki kabel. Dan selain itu, kami juga membuat mesin baris ganda, yang satu baris untuk memproduksi anak tangga dan dinding samping dua profil, tetapi satu kali hanya memproduksi satu profil, tetapi biaya mesin lebih rendah dari dua mesin roll forming. Tetapi Anda dapat melihat, itu membutuhkan banyak proses manual selama produksi, memiliki kapasitas produksi yang rendah.

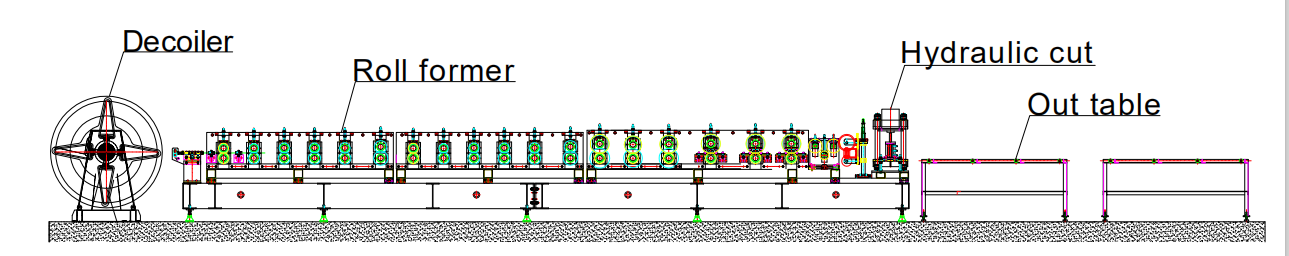

Flow chart:

Decoiler--Pembentuk rol--Pemotongan terbang--Meja keluar

Untuk mengatasi masalah ini, Linbay Machinery bekerja sama dengan pelanggan kami di Tiongkok untuk merancangmesin roll forming tangga kabel tipe baruProfil ini memiliki kapasitas beban yang baik, bentuk yang indah, dan pada saat yang sama memungkinkan produksi dalam jalur produksi yang berkelanjutan dan tanpa gangguan. Ketebalan tipe baru ini adalah 1,8 mm. Dapat menahan gempa bumi kelas 8 dan cocok untuk negara-negara zona gempa bumi dan proyek nuklir, versi ini telah disertifikasi oleh lembaga pengujian profesional. Linbay adalah produsen pertama dan unik dari mesin pembentuk rol tangga kabel ini. Tangga kabel tipe baru yang diproduksi oleh LINBAY ini hanya perlu membeli satu mesin pembentuk rol untuk mewujudkan produksi otomatis. Perforasi tangga kabel ini lebih rumit, anak tangga juga disertai dengan embossment horizontal sehingga setiap dimensi lebar memerlukan cetakan pelubang terpisah, sehingga harga cetakan relatif tinggi. Jika diproduksi oleh mesin pelubang, kita perlu menggunakan mesin pelubang tipe gantry 500 ton. Mempertimbangkan biaya, kita menggunakan stasiun pelubang hidrolik, yang lebih ekonomis, tetapi kecepatan produksi akan jauh lebih lambat. Kecepatan jalur ini sekitar 3-4 meter per menit. Jika kita menggunakan mesin press punch tipe gantry 500 ton, ia melakukan punch 30 kali per menit dengan jarak langkah 300 mm, dan kecepatan produksinya dapat mencapai 9 meter per menit.

Gambar profil ini lebih rumit, dan membutuhkan 25 kali proses pembentukan setelah pelubangan. Karena lembarannya lebih tebal, kami menggunakan dudukan besi cor dengan gerakan horizontal otomatis. Lini produksi ini menggunakan guillotine pasca-pemotongan dan tanpa sisa untuk menghemat bahan baku. Setiap ukuran memiliki bilahnya sendiri. Keuntungan pasca-pemotongan adalah bentuknya lebih indah. Saat ini, tangga kabel jenis baru ini relatif jarang di pasaran, dan memiliki keunggulan harga. Selain tangga kabel, lini produksi ini juga dapat memproduksi baki kabel dengan profil yang sama dengan mengganti cetakan pelubangan, sehingga merupakan lini produksi yang praktis dan merupakan pilihan investasi yang baik.

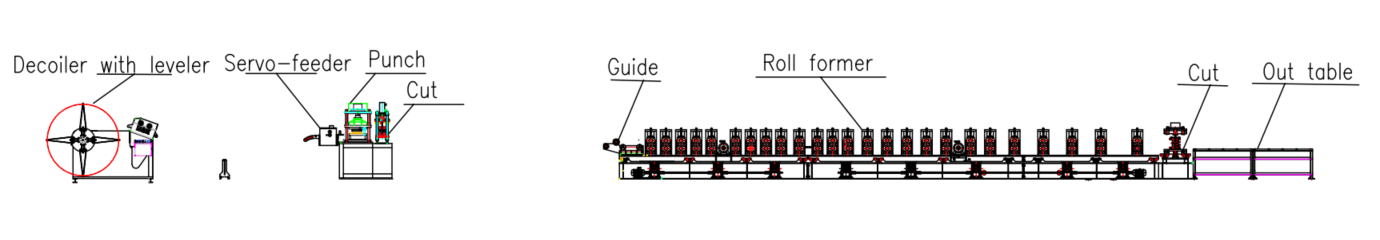

Flow chart:

Decoiler dengan leveler--Pengumpan servo--Pukulan hidrolik--Pemotongan hidrolik awal--Pembentuk rol--Pemotongan hidrolik--Meja luar

Seluruh Proses Mesin Pembentuk Gulungan Tangga Kabel

Spesifikasi Teknis

| Mesin Pembentuk Gulungan Baki Kabel Otomatis | ||

| Bahan yang Dapat Dimesin : | A) Baja Galvanis | Ketebalan (MM): 0,6-1,2, 1-2 |

| B) PPGI | ||

| C) Baja karbon | ||

| Kekuatan luluh : | Tekanan 250 - 550 MPa | |

| Tegangan tarik : | G250 Mpa-G550 Mpa | |

| Decoiler : | Dekoiler manual | * Decoiler hidrolik (Opsional) |

| Sistem pelubangan : | Stasiun pelubangan hidrolik | * Mesin press punching (Opsional) |

| Stasiun pembentukan : | Sesuai dengan gambar profil Anda | |

| Merek motor mesin utama: | Shanghai Dedong (Merek Tiongkok-Jerman) | * Siemens (Opsional) |

| Sistem penggerak : | Penggerak rantai | * Penggerak gearbox (Opsional) |

| Struktur mesin: | Tipe kantilever | * Stasiun Besi Tempa (Opsional) |

| Kecepatan pembentukan : | 10-20 (M/MENIT) | * Atau sesuai dengan gambar profil Anda |

| Bahan rol : | GKR 15 | * SKD-11 (Opsional) |

| Sistem pemotongan : | Pasca pemotongan | * Pra-pemotongan (Opsional) |

| Merek pengubah frekuensi: | Yaskawa | * Siemens (Opsional) |

| Merek PLC: | Panasonic | * Siemens (Opsional) |

| Catu daya : | Tegangan 380V 50Hz 3ph | * Atau sesuai kebutuhan Anda |

| Warna mesin : | Biru industri | * Atau sesuai kebutuhan Anda |

Bagaimana LINBAY MACHINERY melakukan instalasi selama COVID-19?

Pemasangan mesin roll forming selama COVID-19 gratis!

Dengan ini LINBAY akan menjelaskan bagaimana kami melakukan pemasangan mesin roll forming kami.

Pertama, kami menyesuaikan mesin di pabrik kami, kami akan menanyakan ukuran mana yang akan Anda produksi terlebih dahulu, kami menempatkan mesin dalam ukuran yang akan diproduksi dan menyesuaikan semua parameter yang benar sebelum pengiriman, sehingga Anda tidak perlu mengubah apa pun saat Anda mendapatkan mesin ini.

Kedua, saat kami membongkar mesin untuk debugging, kami merekam video agar Anda tahu cara menghubungkannya. Setiap mesin memiliki videonya masing-masing. Dalam video tersebut, akan ditunjukkan cara menghubungkan kabel dan tabung, memasukkan oli, menyusun struktur fisik, dll.

Berikut adalah contoh video tersebut: https://youtu.be/p4EdBkqgPVo

Ketiga, saat Anda menerima peralatannya, Anda akan memiliki grup WhatsApp atau WeChat, teknisi kami (dia berbicara bahasa Inggris dan Rusia) dan saya (saya berbicara bahasa Inggris dan Spanyol) akan berada di grup tersebut untuk membantu Anda jika ada keraguan.

Keempat, kami mengirimi Anda manual dalam bahasa Inggris atau Spanyol sehingga Anda memahami semua arti tombol dan cara menyalakan mesin.

Kami memiliki kasus di mana klien saya dari Vietnam menerima mesinnya pada tanggal 25 November, dan memasangnya di merek pada malam hari, dan mulai berproduksi pada tanggal 26 November. Selain itu, kami telah mencapai banyak keberhasilan dalam memasang mesin yang lebih rumit. Tidak ada masalah dengan pemasangan mesin Anda. LINBAY menawarkan kualitas dan layanan terbaik untuk klien kami, terutama dalam situasi ini. Anda tidak perlu menunggu hingga COVID berlalu. Anda dapat langsung memproduksi profil dengan mesin kami.

Tanya Jawab

1. Q: Pengalaman apa saja yang Anda miliki dalam memproduksimesin pembentuk gulungan tangga kabel?

A: Kami telah mengekspor lini produksi baki kabel ke Rusia, Australia, Argentina, Malaysia, dan Indonesia. Kami telah memproduksibaki kabel berlubang, baki kabel CT, baki kabel tanggadan lain-lain. Kami yakin dapat memecahkan masalah baki kabel Anda.

2. Q: Bisakah saya hanya menggunakan satu baris untuk memproduksibaki kabel tangga dan penutup baki?

A: Ya, Anda tentu saja dapat menggunakan satu lini produksi untuk memproduksi baki kabel dan penutup baki. Proses penggantiannya sederhana, Anda dapat menyelesaikannya dalam waktu setengah jam. Dengan cara ini, biaya dan waktu Anda akan sangat berkurang.

3. Q: Berapa lama waktu pengirimannya?mesin baki kabel tangga?

A: 120 hari hingga 150 hari tergantung pada gambar Anda.

4. T: Berapa kecepatan mesin Anda?

A: Kecepatan kerja mesin bergantung pada proses drawing, terutama punch drawing. Kecepatan normalnya sekitar 20 m/menit. Silakan kirimkan gambar Anda dan beri tahu kami kecepatan yang Anda butuhkan, kami akan menyesuaikannya untuk Anda.

5. T: Bagaimana Anda mengendalikan presisi dan kualitas mesin Anda?

A: Rahasia kami untuk menghasilkan presisi seperti itu adalah pabrik kami memiliki lini produksi sendiri, mulai dari pelubangan cetakan hingga rol pembentuk. Setiap komponen mekanis diselesaikan secara independen oleh pabrik kami sendiri. Kami secara ketat mengontrol akurasi di setiap langkah, mulai dari desain, pemrosesan, perakitan, hingga kontrol kualitas. Kami tidak mau mengambil jalan pintas.

6. T: Apa sistem layanan purna jual Anda?

A: Kami tidak ragu memberikan masa garansi dua tahun untuk seluruh lini, dan lima tahun untuk motor. Jika terjadi masalah kualitas yang disebabkan oleh faktor non-manusia, kami akan segera menanganinya dan siap melayani Anda 7x24 jam. Satu pembelian, perawatan seumur hidup untuk Anda.

1. Dekoiler

2. Memberi makan

3.Meninju

4. Dudukan pembentuk gulungan

5. Sistem penggerak

6. Sistem pemotongan

Yang lain

Meja luar