100% Original Iron Rolling Machine - Strut and Rail roll forming machine – Linbay Machinery Detail:

Description:

Steel Strut&Rail Roll Fomring Machine includ Door Rail Roll Fomring Machine, Steel C Channel Roll Forming Machine, Solar Rack Roll Forming Machine etc. The working thickness can be 1.5-2.5mm. The Max. working speed can be 25m/min. We adopt gearbox driving system to keep our machine work with high speed and prolong the service life.

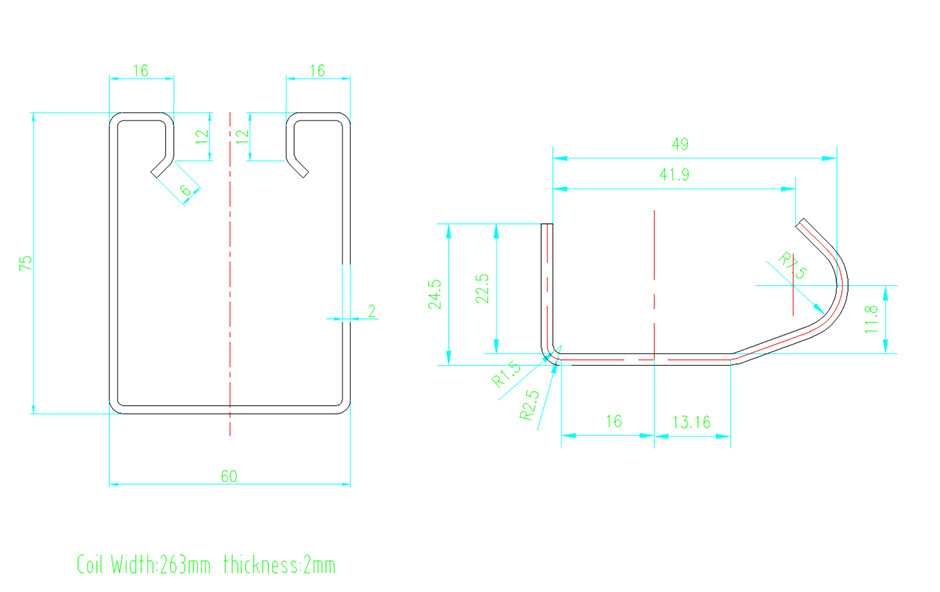

Profile:

Technical specification:

|

Steel Strut& Rail roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-2.5 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

17 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Gearbox drive | Chain drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

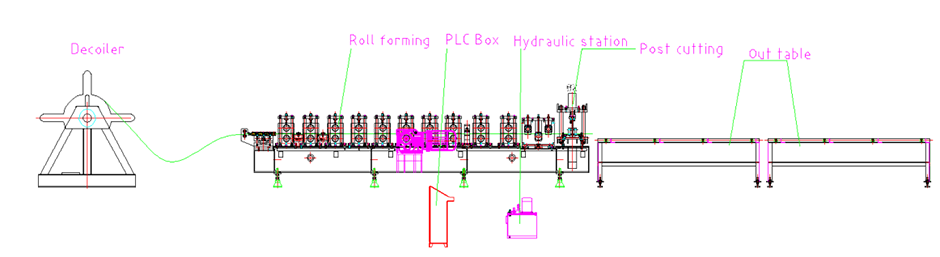

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Roll Forming Machine Design Technology Introduction

Sticking to the principle of "Super High-quality, Satisfactory service" ,We are striving to generally be a very good business partner of you for 100% Original Iron Rolling Machine - Strut and Rail roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Libya, Luxembourg, South Africa, We attained ISO9001 which provides solid foundation for our further development. Persisting in "High quality, Prompt Delivery, Competitive Price", we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments. It is our great honor to meet your demands. We are sincerely expecting your attention.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.

Send your message to us:

-

Well-designed Cold Tile Steel Sheet Roll Formin...

-

Manufacturing Companies for Roof T Forming Mach...

-

Personlized Products Steel Tile Roll Forming Ma...

-

2018 China New Design Hoist Suspended Platform ...

-

Price Sheet for High Precision Roll Forming Mac...

-

Reliable Supplier C And Z Purlin Forming Machin...