Description

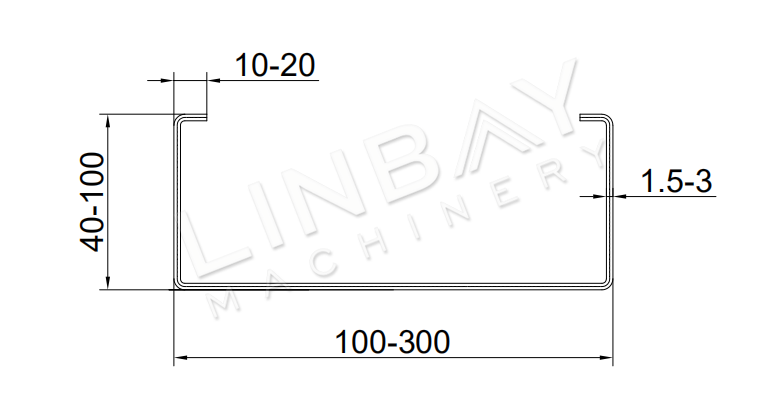

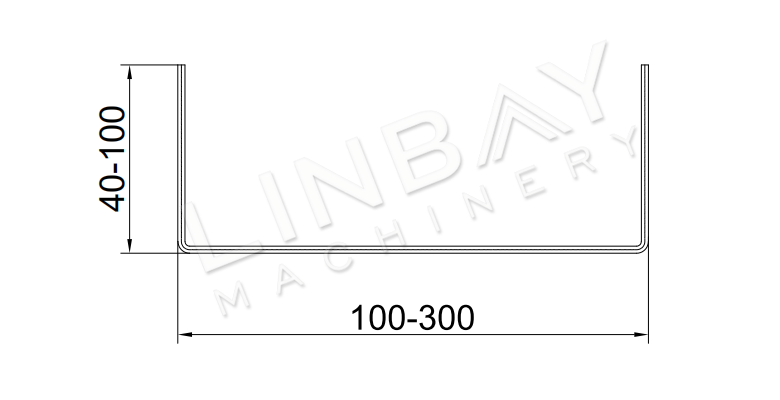

Purlin roll forming machine is the most popular and has an extensive use in Metal Building Systems, Huge RoofingSolutions, Construction and Renovation Projects etc. Our Purlin roll forming machine could produce C purlin, U purlin, Z purlin, machineable size range as follow: Width:0-300mm, Height: 50-100mm, Thickness:1.5-3mm. Raw material could be: cold-rolled steel, Galvanized steel, PPGI, high-tensil steel. The finished purlins meet JIS G standard, ASTM International Standard, AS/NZS International Standard etc. Simply the best purlin machine for your project.

According to your section profile, size range, thickness range we could provide you different solutions of purlin roll forming machine to manufacturer a complete range of structual purlins(height and width change using automatic system by motors):

Only to produce C/U section, change time: few seconds

C/U/Z section-manual change whole line from C to Z, change time: 10 minutes

C/U/Z/M section-manual change 4 stations from C to Z, change time: 2 minutes

C/U/Z/M section-automatically change from C to Z, change time: few seconds

Regarding the cutting unit ,you can choose the pre-cut, post cut or both. Gearbox driving system with cast iron stands are more durable and recommendable.

If you only need to produce few sizes, we also suggest manually change sleeves, it’s more affordable.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of Linbay Machinery will ensure you obtain perfectly functional profiles.

Application

Real Case A

Description:

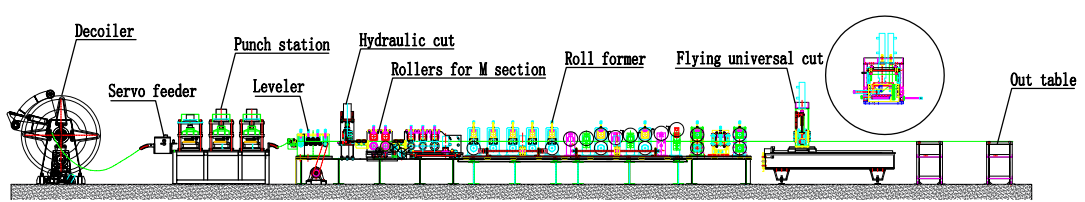

This C/Z/U/M purlin roll forming machine is our new innovation in 2018. This machine has been exported to Mumbai, India. This excellent machine could make C section, U section, M section and Z section purlins with thickness 1.5-4mm. The purlin line is equipped with servo feeder, leveler and automatic width-change and height-change system, also from C to Z only need to change 4 stations manually with change wheel. It could be operated whole line with one operator easily in 2 minutes. Linbay Machinery is your best choice for purlin roll forming solution.

Real Case B

Description:

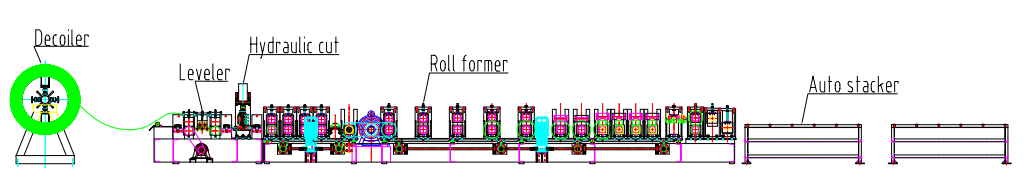

This CZ purlin quick changeable roll forming machine is a mature production line. We have 10 years of experience in this machine. It’s more affordable, economic and it’s our best-seller. It adopts pre-cut system to avoid changing too many blades, which saves time for you. Sizes can be changed by motor automatically. Changing time from C to Z need 10 minutes. Linbay Machinery is your best choice for purlin roll forming solution.

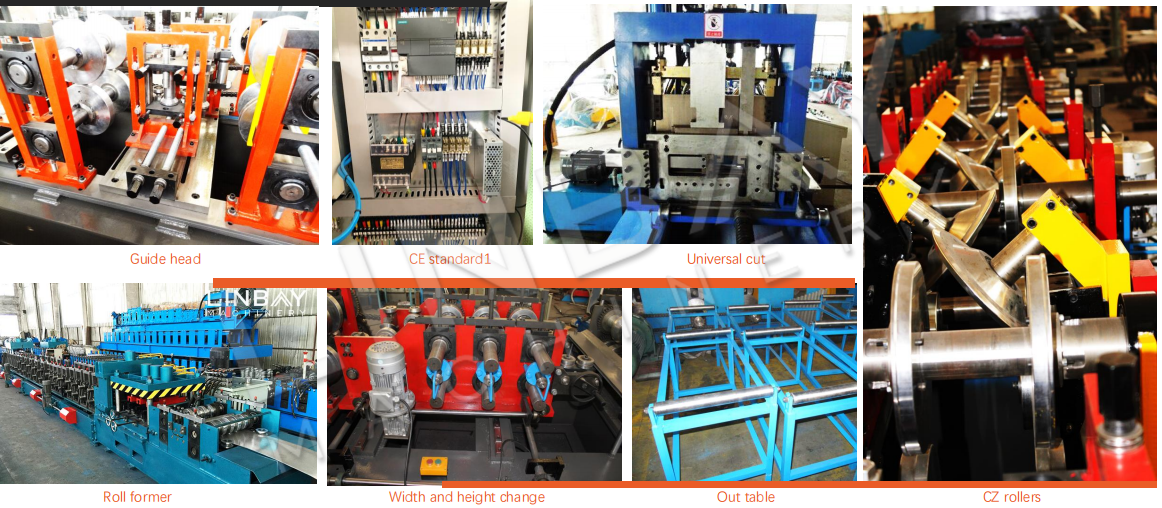

Whole production line of Purlin roll forming machine

Technical Specifications

| Purlin Roll Forming Machine | ||

| Machinable Material : | A) Galvanized Coil | Thickness(MM): 1.5-3 |

| B) PPGI | ||

| C) Carbon steel Coil | ||

| Yield strength : | 250 - 550 Mpa | |

| Tensil stress : | G350 Mpa-G550 Mpa | |

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Punching system : | Hydraulic punching station | * Punching press (Optional) |

| Forming station : | 18-20 stations | |

| Main machine motor brand : | Shanghai Dedong (Sino-Germany Brand) | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Wall panel station | * Forged Iron station (Optional) |

| Forming speed : | 10-20 (M/MIN) | * Or according to your profile drawings |

| Rollers’ material : | Steel #45 | * GCr 15(Optional) |

| Cutting system : | Pre-cutting | * Post- universal cutting (Optional) |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

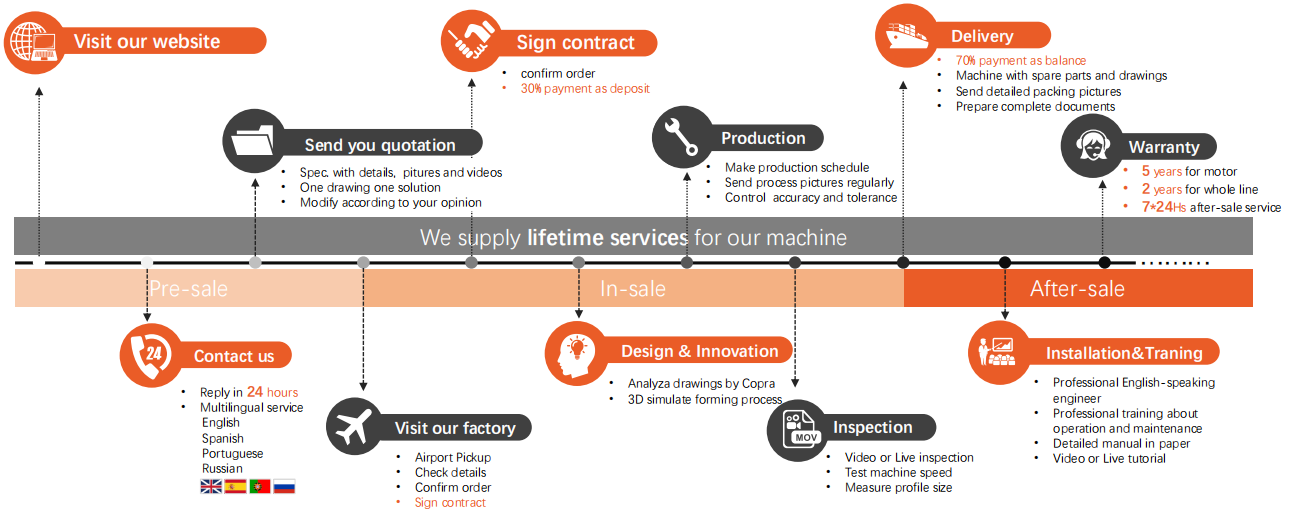

Purchase Service

Q&A

1. Q: What kinds of experience do you have in producing purlin roll forming machine?

A: We have exported C/Z purlin roll forming machine to to India, Serbia, UK, Peru, Argentina, Chile, Hondulas, Bolivia, Egypt, Poland, Russia, Spain, Romania etc. It’s the most popular roll forming machine of all.

In Construction Industries, we are able to manufacture more machines like main channel roll forming machine, furring channel roll forming machine, ceiling roll forming machine, wall angle roll formign machine, light gauge steel roll forming machine, drywall roll forming machine, stud roll forming machine, track roll forming machine, metal deck(floor deck) roll forming machine, vigacero roll forming machine, roof/wall panel roll forming machine, roof tile roll forming machine etc.

Simply the best steel frame machine for your project.

2. Q: How many sizes can produce this machine?

A: This machine can produce C purlin, Z purlin, U purlin, Sigma purlin, and each section could produce many sizes, width range is 80-300mm, height range is 50-100mm, recommendable thickness range is 1.5-3mm. It’s your best and affordable choice for steel frame.

3. Q: What is delivery time of cable tray machine?

A: 60 days to 70 days depends on your drawing.

4. Q: What is your machine speed?

A: Normally forming speed is around 20m/min (adjustable) with flying cutting for thickness 1.5mm. For 3mm, forming speed is lower, around 15m/min.

5. Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6. Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table