2018 China New Design Rainwater Gutter Machine - PU Sandwich Panel Production Line – Linbay Machinery Detail:

Description:

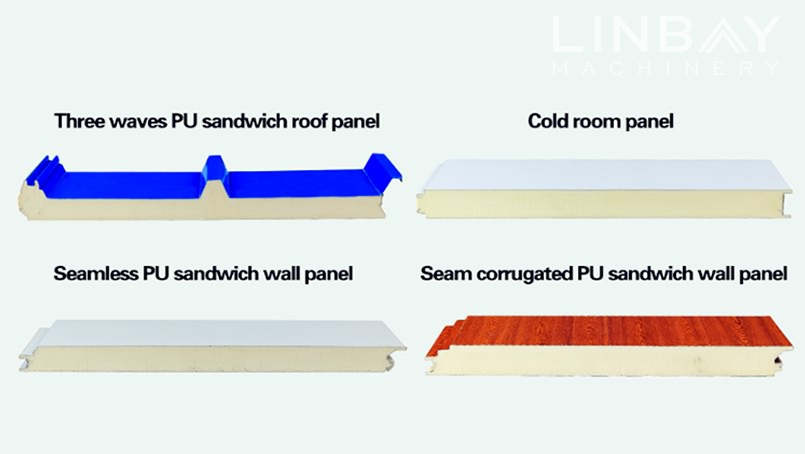

This PU Sandwich Panel Production Line is to manufacture polyurethane or phenol laminated sandwich panel with color steel facings.

The continuous production line for rigid polyfoam laminated panel with color steel facings is a kind of specialized equipment used for producing color-steel sided sandwich panels with the middle layer of anti-combustion polyurethane, polyisocyanurate or phenolic foam plastic. The thickness of the produced sandwich panel ranges from 0 to 10 mm, the width between 750 to 1000 mm and the length on request. Also we offer Rock Wool Panel Production Line, Glass Wool Panel Production Line.

Profile:

Technical specification:

|

PU Sandwich Panel Production Line |

||

|

NO. |

Composing of product line: |

Amount |

|

1 |

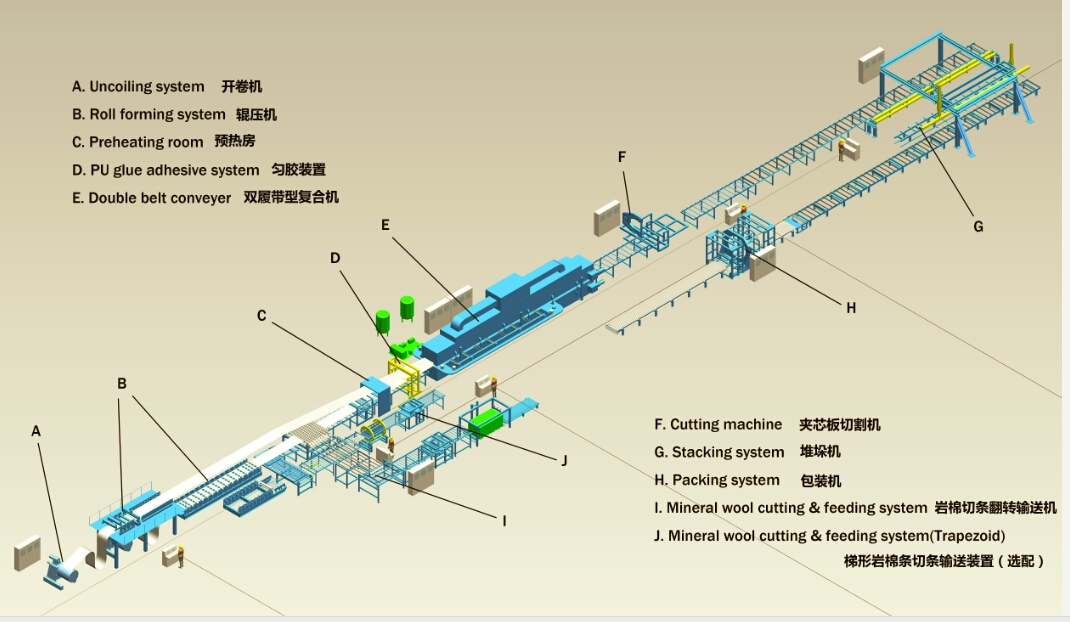

Hydraulic Uncoilers with transporter car |

2 |

|

2 |

Steel sheet transverse cutting device, steel sheet |

2 |

| surface PVC film covering device | ||

|

3 |

Roll forming machine |

4 |

|

4 |

Conveyer |

1 |

|

5 |

Pre-heating room |

1 |

|

6 |

PUR/PIR two components Liquid mixing and |

1 |

| injecting section for foaming (high pressure pump, | ||

| made in China) | ||

|

7 |

Foaming and the PUR/PIR foam maturing |

1 |

| machine /double belt structure 18m length include | ||

| side nylon seal blocks to make 6 kinds thickness | ||

| panel, one set of blocks for supporting roof panel . | ||

|

8 |

Heating and heat insulation system |

1 |

|

9 |

Panel automatically cutting system |

1 |

|

10 |

Electric control system |

1 |

Flow Chart:

Product detail pictures:

Related Product Guide:

Understanding Roll Forming Machines

Starting and Growing Business With CNC Roll Forming Machine Financing and Leasing

Our firm aims to operating faithfully, serving to all of our shoppers , and working in new technology and new machine consistently for 2018 China New Design Rainwater Gutter Machine - PU Sandwich Panel Production Line – Linbay Machinery, The product will supply to all over the world, such as: Cannes, Saudi Arabia, Karachi, We follow superior mechanism to process these products that ensure optimum durability and reliability of the products. We follow latest effective washing and straightening processes that allow us to offer unmatched quality of products for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.

Send your message to us:

-

OEM/ODM Factory Power Scaffolding Platforms - ...

-

New Arrival China Electric Scaffolding - Corru...

-

OEM Factory for Rolling Shutter Machine - C Z ...

-

Fast delivery Corrugated Roofing Machine - Ste...

-

Factory Cheap Downspout Roll Forming Machine Ch...

-

Manufacturer for Wall/Roof Panel Roll Forming M...