2018 High quality Lightweight Wall Panel Production Line - Step Beam roll forming machine – Linbay Machinery Detail:

Description:

Square Pipe Roll Forming Machine include Step Beam Roll Formng Machine. Beam rack can both store multi-veriety goods with small quantity and also unified goods with big quantity. And square pipe can be used as down pipe also. Normally thickness can be formed at 1.5-3mm and the speed is about 10-20m/min.This machine is widely used in high warehouses.

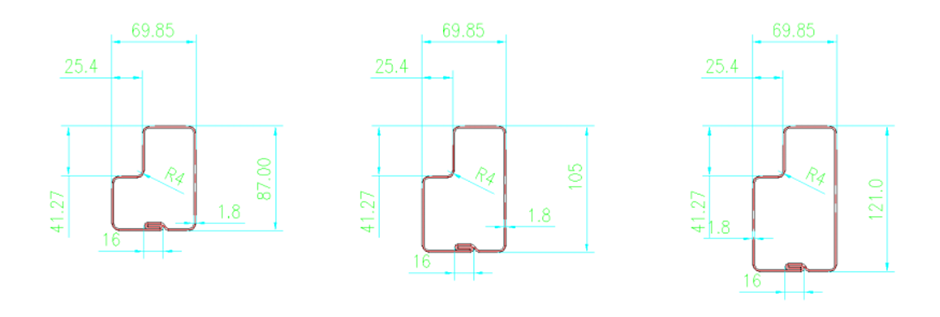

Profile:

Technical specification:

|

Warehouse Step Beam/Square Pipe Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-1.8,1.5-3 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

31 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel station |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

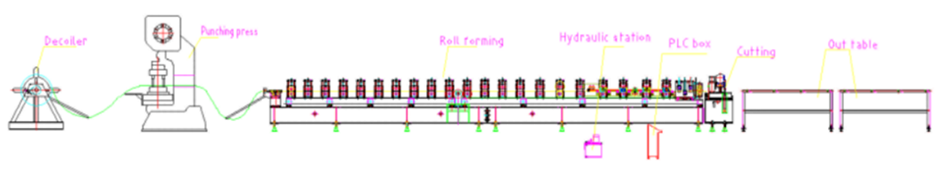

Flow Chart:

Product detail pictures:

Related Product Guide:

Starting and Growing Business With CNC Roll Forming Machine Financing and Leasing

Understanding Roll Forming Machines

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for 2018 High quality Lightweight Wall Panel Production Line - Step Beam roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Victoria, Jamaica, Indonesia, Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality products and perfect pre-sales /after-sales service is our idea, some clients had cooperated with us for more than 5 years.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!

Send your message to us:

-

2018 wholesale price C Channel Roll Forming Mac...

-

Professional Design Single Layer Roof Sheet Mac...

-

Well-designed Cold Tile Steel Sheet Roll Formin...

-

Factory Outlets C Channel Purline Roll Forming ...

-

Quoted price for Pu Panel Production Line - C ...

-

Professional China Price Matel Roofing Sheet Ar...