2018 Latest Design Standing Seam Roof Sheet Roll Forming Machine - Gutter roll forming machine – Linbay Machinery Detail:

Description:

Gutter Roll Forming Machine normally work with 0.4-0.6mm thickness raw material to make gutters and drains. Normal working speed is aroun 10-20m/min. We adopt torri stand structure, it’s more beautiful and more table when the machine working.

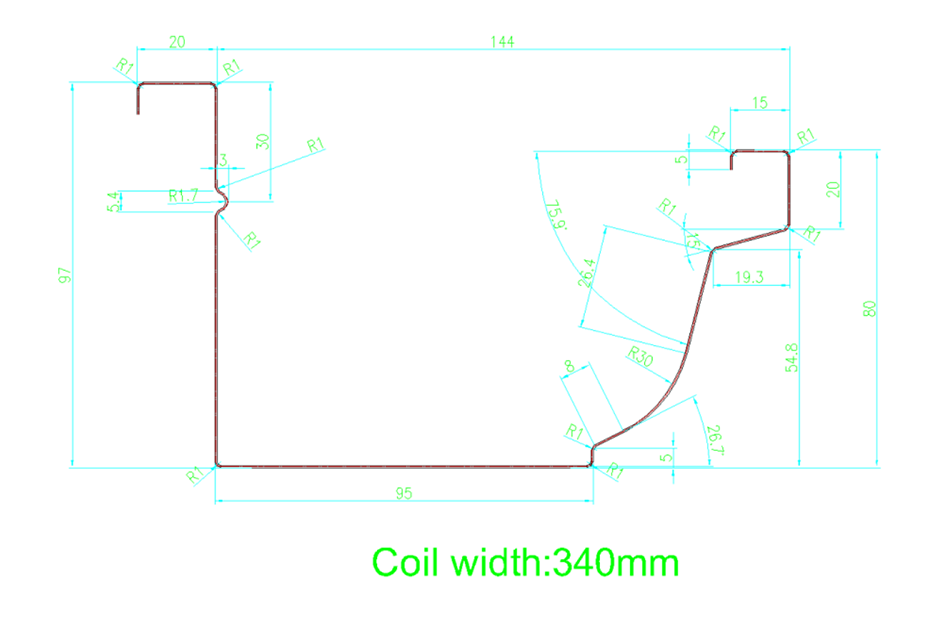

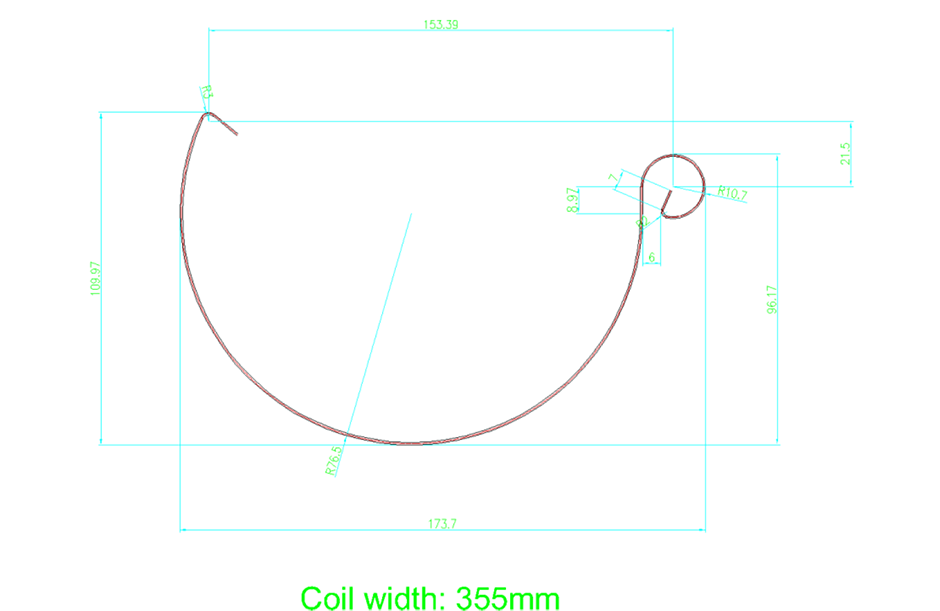

Profile:

Technical specification:

|

Gutter roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.4-0.6 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

19 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

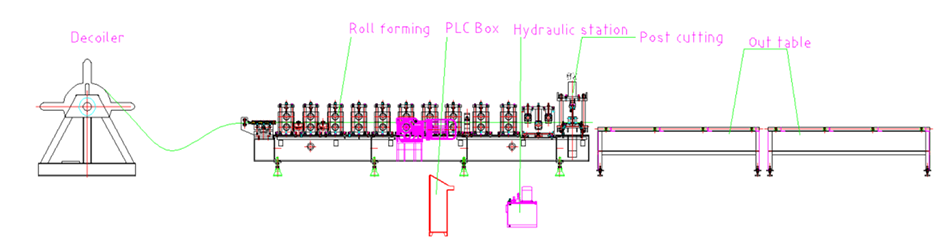

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Cold Roll Forming Machines – New Army in Steel Construction Industry

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for 2018 Latest Design Standing Seam Roof Sheet Roll Forming Machine - Gutter roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Namibia, Oman, Denmark, We provide OEM services and replacement parts to meet the varying needs of our customers. We give competitive price for quality solutions and we are going to make certain your shipment is handled quickly by our logistics department. We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.

Send your message to us:

Write your message here and send it to us

-

OEM Customized Door Rail Roll Fomring Machine -...

-

Fast delivery Two Layers Roll Forming Machine -...

-

2018 New Style Door Frame Section Rmanufacturin...

-

Excellent quality High Quality Frp Corrugated S...

-

High reputation Roof Sheet Machine - Door fram...

-

Low MOQ for Metal Roof Sheet Roll Forming Machi...