8 Years Exporter Double Roofing Sheet Machine - PU Sandwich Panel Production Line – Linbay Machinery Detail:

Description:

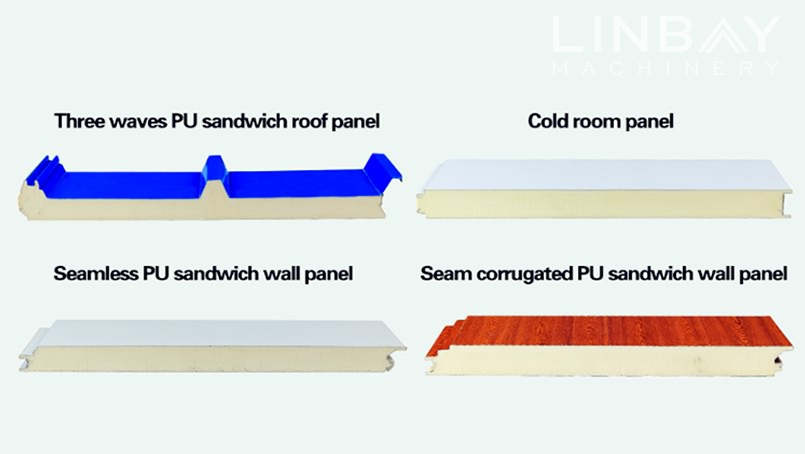

This PU Sandwich Panel Production Line is to manufacture polyurethane or phenol laminated sandwich panel with color steel facings.

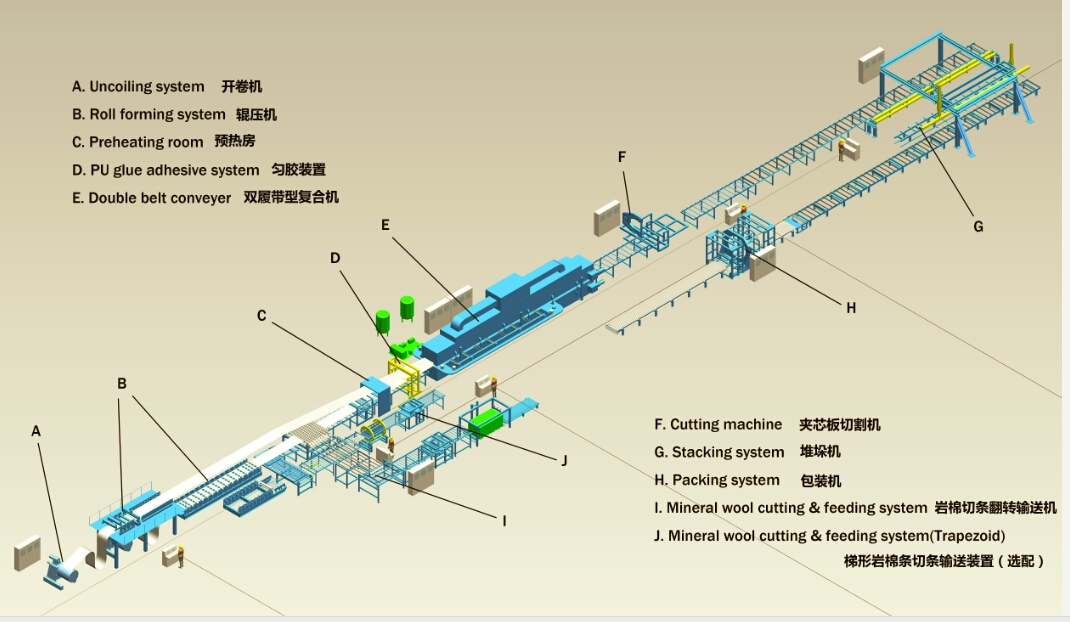

The continuous production line for rigid polyfoam laminated panel with color steel facings is a kind of specialized equipment used for producing color-steel sided sandwich panels with the middle layer of anti-combustion polyurethane, polyisocyanurate or phenolic foam plastic. The thickness of the produced sandwich panel ranges from 0 to 10 mm, the width between 750 to 1000 mm and the length on request. Also we offer Rock Wool Panel Production Line, Glass Wool Panel Production Line.

Profile:

Technical specification:

|

PU Sandwich Panel Production Line |

||

|

NO. |

Composing of product line: |

Amount |

|

1 |

Hydraulic Uncoilers with transporter car |

2 |

|

2 |

Steel sheet transverse cutting device, steel sheet |

2 |

| surface PVC film covering device | ||

|

3 |

Roll forming machine |

4 |

|

4 |

Conveyer |

1 |

|

5 |

Pre-heating room |

1 |

|

6 |

PUR/PIR two components Liquid mixing and |

1 |

| injecting section for foaming (high pressure pump, | ||

| made in China) | ||

|

7 |

Foaming and the PUR/PIR foam maturing |

1 |

| machine /double belt structure 18m length include | ||

| side nylon seal blocks to make 6 kinds thickness | ||

| panel, one set of blocks for supporting roof panel . | ||

|

8 |

Heating and heat insulation system |

1 |

|

9 |

Panel automatically cutting system |

1 |

|

10 |

Electric control system |

1 |

Flow Chart:

Product detail pictures:

Related Product Guide:

Understanding Roll Forming Machines

Guide On How To Use a Roll Forming Machine

We have been ready to share our knowledge of advertising worldwide and recommend you suitable products at most aggressive costs. So Profi Tools present you ideal price of money and we've been ready to create with each other with 8 Years Exporter Double Roofing Sheet Machine - PU Sandwich Panel Production Line – Linbay Machinery, The product will supply to all over the world, such as: Juventus, Borussia Dortmund, Italy, Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We'll work whole-heartedly to improve our solutions and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.

Send your message to us:

-

Factory Price For China Manufaturer - Ridge Ca...

-

OEM/ODM Supplier Steel Roof Forming Machine - ...

-

OEM/ODM Factory Power Scaffolding Platforms - ...

-

China Cheap price R Panel Roll Forming Machine ...

-

Lowest Price for Iron Roll Forming Machine - D...

-

Wholesale OEM/ODM Steel Sheet Roll Forming Mach...