Best Price for C Shape Roll Forming Machine - Shelf Rack roll forming machine – Linbay Machinery Detail:

Description:

Goods Shelf Roll Forming Machine including Shelf Roll Forming Machine, Pallet Rack Roll Forming Machine.Pallet rack can both store multi-veriety goods with small quantity and also unified goods with big quantity. Normally thickness can be formed at 2.5mm and the speed is about 20-30m/min.This machine is widely used in high warehouses.

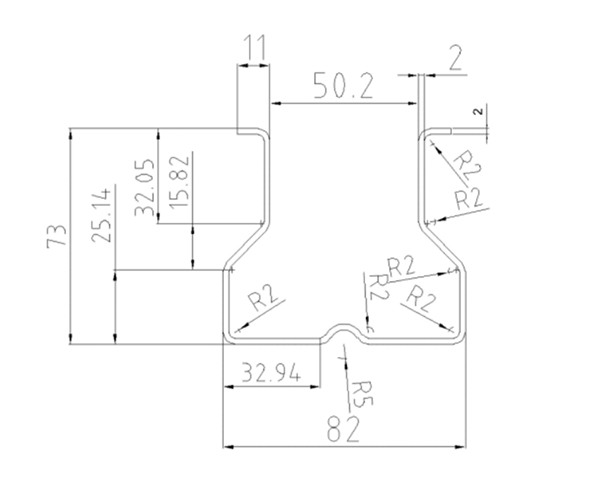

Profile:

Technical specification:

|

Warehouse Pallet Rack/Goods Shelf Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-2.5 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

20 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel station |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

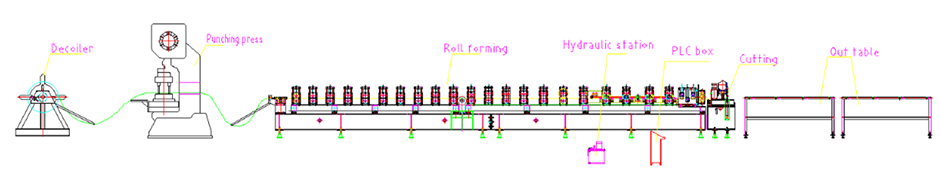

Flow Chart:

Product detail pictures:

Related Product Guide:

Understanding Roll Forming Machines

Roll Forming Machine Design Technology Introduction

Innovation, excellent and reliability are the core values of our company. These principles today much more than ever form the basis of our success as an internationally active mid-size business for Best Price for C Shape Roll Forming Machine - Shelf Rack roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: California, Munich, Guyana, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!

Send your message to us:

-

Factory made hot-sale Double Layer Roll Forming...

-

Renewable Design for Arch Roll Forming Machine ...

-

OEM China Door Making Machine - Highway Guardr...

-

Factory wholesale Rock Wool Panel Production Li...

-

18 Years Factory Stud And Track Frame Forming M...

-

China Wholesale Fully Automatic Roll Forming Ma...