Cheap price Glazed Tiles Roll Forming Machine - Gutter roll forming machine – Linbay Machinery Detail:

Description:

Gutter Roll Forming Machine normally work with 0.4-0.6mm thickness raw material to make gutters and drains. Normal working speed is aroun 10-20m/min. We adopt torri stand structure, it’s more beautiful and more table when the machine working.

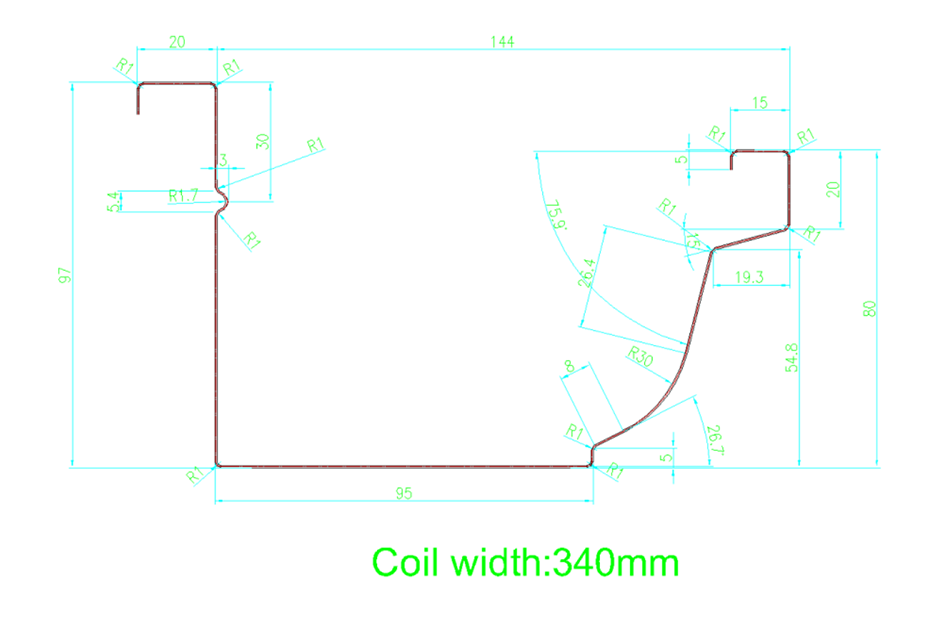

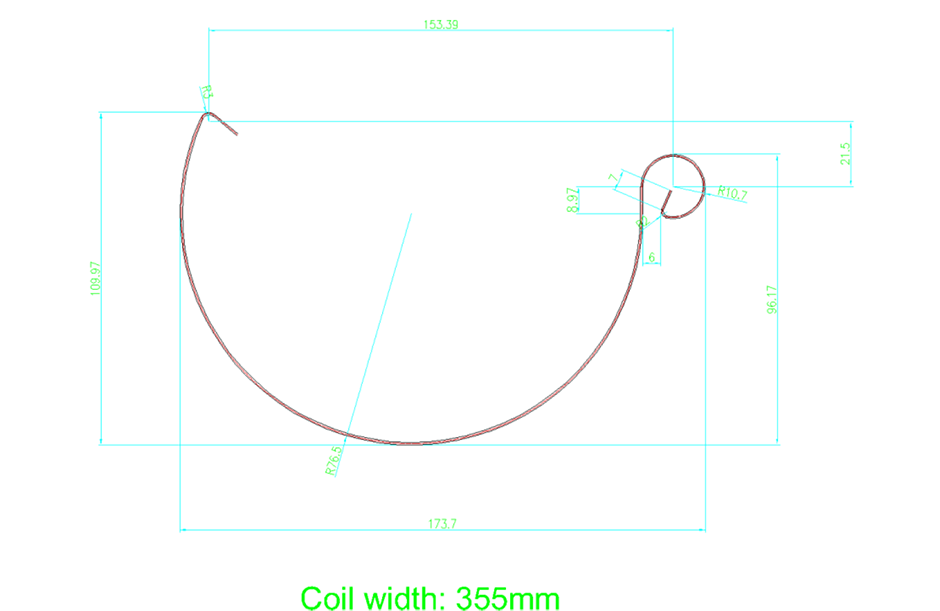

Profile:

Technical specification:

|

Gutter roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.4-0.6 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

19 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

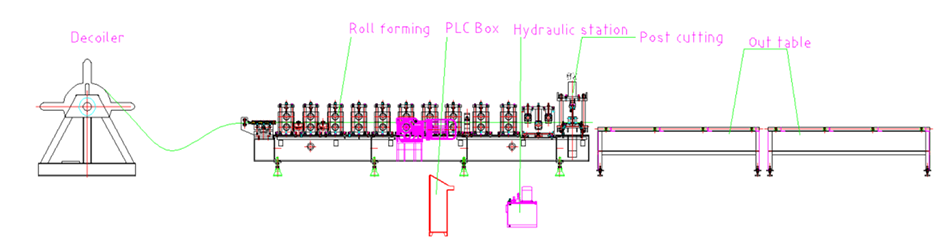

Flow Chart:

Product detail pictures:

Related Product Guide:

Roll Forming Machine Design Technology Introduction

Understanding Roll Forming Machines

All we do is always associated with our tenet " Customer first, Trust first, devoting on the food packaging and environmental protection for Cheap price Glazed Tiles Roll Forming Machine - Gutter roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Colombia, Kuwait, Canada, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We've been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!

Send your message to us:

Write your message here and send it to us

-

Factory Price Full Automatic Cable Tray Roll Fo...

-

Factory Price Full Automatic Cable Tray Roll Fo...

-

Factory For Automatic Steel Roll Forming Machin...

-

High Quality for Painting Curtain Wall Cleaning...

-

Well-designed Cold Tile Steel Sheet Roll Formin...

-

Best-Selling Fence Support Pipe Roll Forming Ma...