China Factory for Truss Profile Roll Forming Machine - Downspout Pipe roll forming machine – Linbay Machinery Detail:

Description:

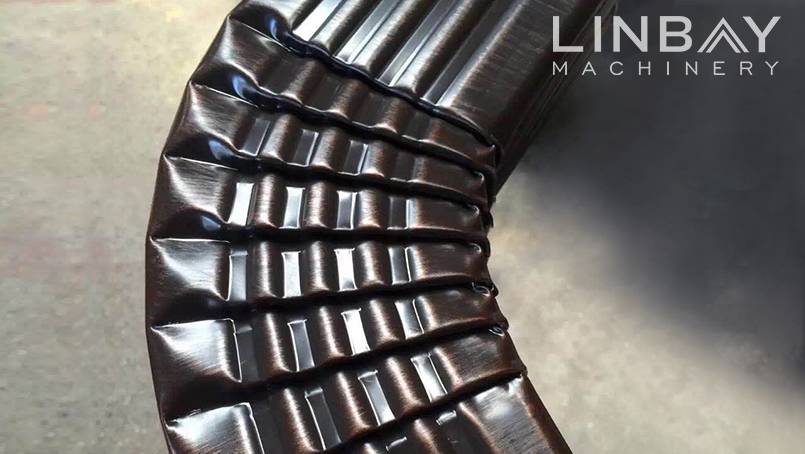

Downspout/Down Pipe Roll Forming Machine can produce the water pipes with perfect surface. It has two types: round pipe and square pipe.

This line include Uncoiler ,Rollforming unit and cutting unit also the Pipe bender unit.

The thickness can be formed Min. 0.3mm thin and Max.2.0mm thick.

The Pipe Bender can be bent the product as 90 degree and retracted for connecting pipe ends.

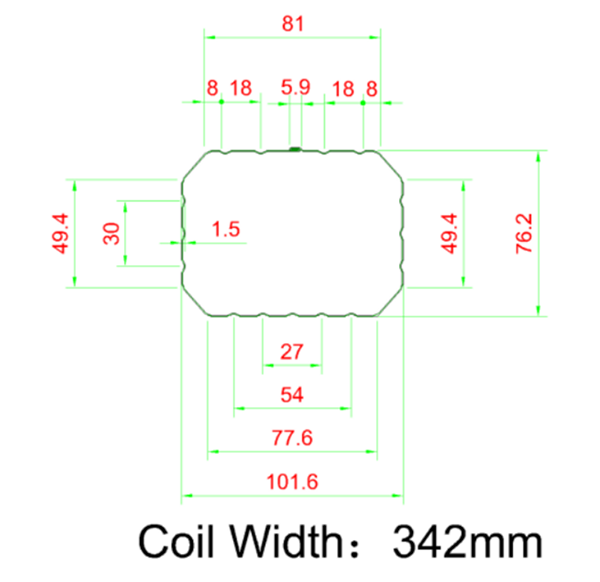

Profile:

Technical specification:

|

Downspout Pipe/Round pipe/ Square pipe roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-2 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

19 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

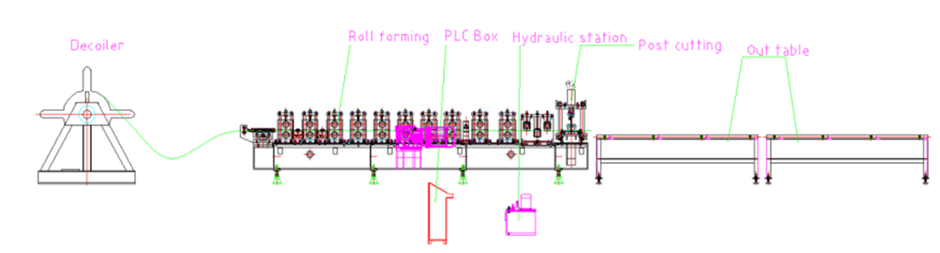

Flow Chart:

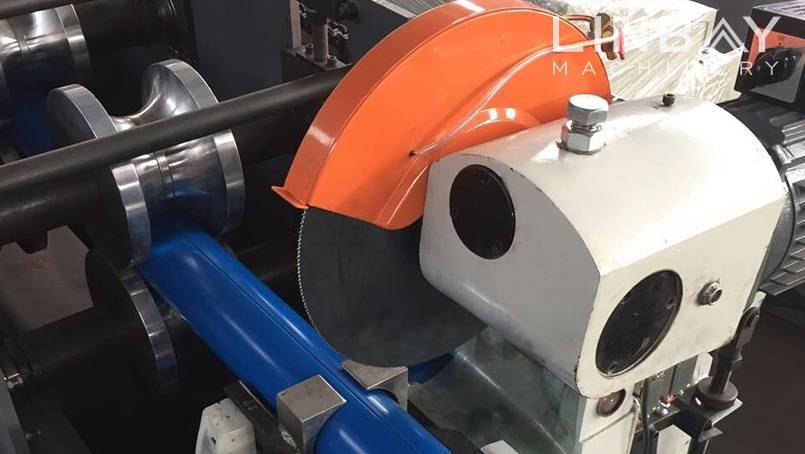

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Roll Forming Machine Design Technology Introduction

We also present product or service sourcing and flight consolidation products and services. We have our possess manufacturing facility and sourcing place of work. We can easily supply you with almost every type of product or service connected to our item variety for China Factory for Truss Profile Roll Forming Machine - Downspout Pipe roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Tajikistan, Pakistan, Libya, We have more than 10 years exported experience and our products have expored more than 30 countries around the word . We always hold the service tenet Client first,Quality first in our mind,and are strict with product quality. Welcome your visiting!

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!

Send your message to us:

-

Wholesale Dealers of T Roll Machine - Highway ...

-

Super Lowest Price Roof Tile Roll Forming Machi...

-

2018 High quality Solar Panel Machine - C Z Pu...

-

Reliable Supplier Roll Forming Machine Manufact...

-

Reliable Supplier C And Z Purlin Forming Machin...

-

Fast delivery Two Layers Roll Forming Machine -...