China New Product Roofing Sheet Machine - Shelf Rack roll forming machine – Linbay Machinery Detail:

Description:

Goods Shelf Roll Forming Machine including Shelf Roll Forming Machine, Pallet Rack Roll Forming Machine.Pallet rack can both store multi-veriety goods with small quantity and also unified goods with big quantity. Normally thickness can be formed at 2.5mm and the speed is about 20-30m/min.This machine is widely used in high warehouses.

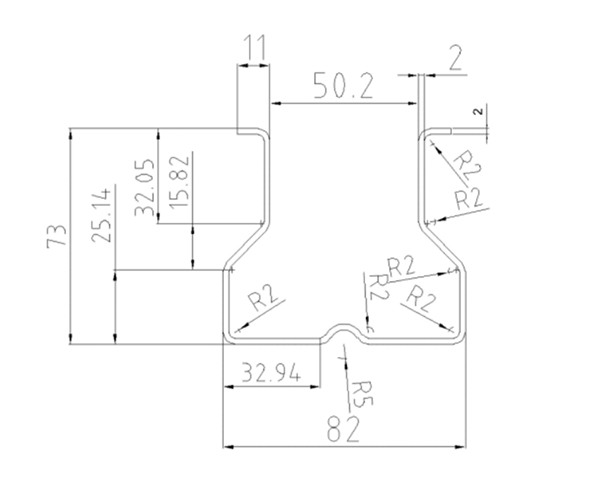

Profile:

Technical specification:

|

Warehouse Pallet Rack/Goods Shelf Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-2.5 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

20 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel station |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

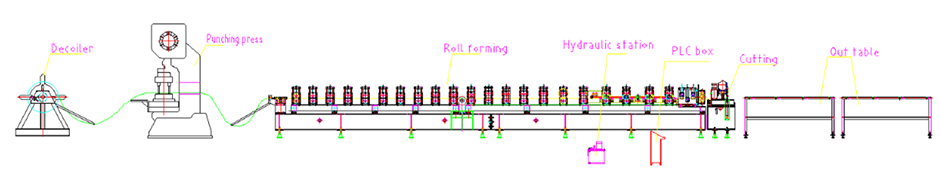

Flow Chart:

Product detail pictures:

Related Product Guide:

Understanding Roll Forming Machines

Cold Roll Forming Machines – New Army in Steel Construction Industry

We usually think and practice corresponding for the change of circumstance, and grow up. We aim at the achievement of a richer mind and body as well as the living for China New Product Roofing Sheet Machine - Shelf Rack roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Mauritius, Moscow, Saudi Arabia, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.

Send your message to us:

-

Cheap PriceList for Z Channel Roll Forming Mach...

-

Hot Selling for Zlp630 Steel Suspended Working ...

-

Discount Price Cnc Automatic Sheet Metal Bendin...

-

OEM China Wall And Roof Machine - PU Sandwich ...

-

High definition Steel Molding Machine - Cable ...

-

OEM/ODM Supplier Galvanized Floor Decking Roll ...