Chinese Professional Customize Supermarket Shelf Panel Machine - Corrugated Panel roll forming machine – Linbay Machinery Detail:

Description:

This Roof Panel/Wall Panel Roll Forming Machine can produce any kinds of thickness of corrugated sheets, trapezoidal sheets. Normal thickness is from 0.3-0.8mm. The Corrugated Steel Silo Roll Forming Machine can work with Max. thickness 4.0-5.0mm, its product is used as corrugated steel silo. In South Africa, the Trapezoidal Panel Roll Forming Machine also is known as IBR Roll Forming Machine.

There are different kinds of machine structures, such as Torri stands, Thick wall stands and cast iron stands.

Normal speed is 10-15m/min. Max. Working speed can reach at 25m/min.

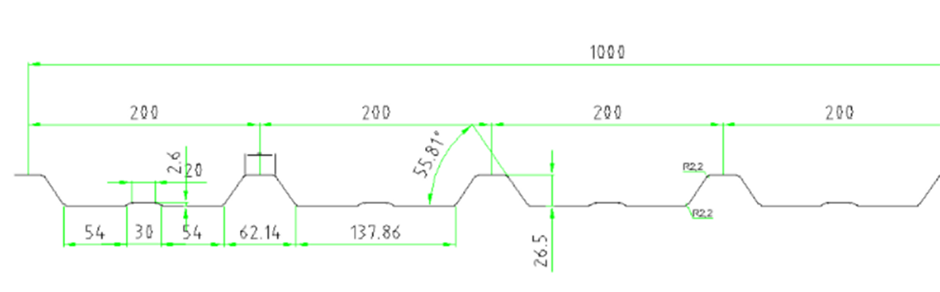

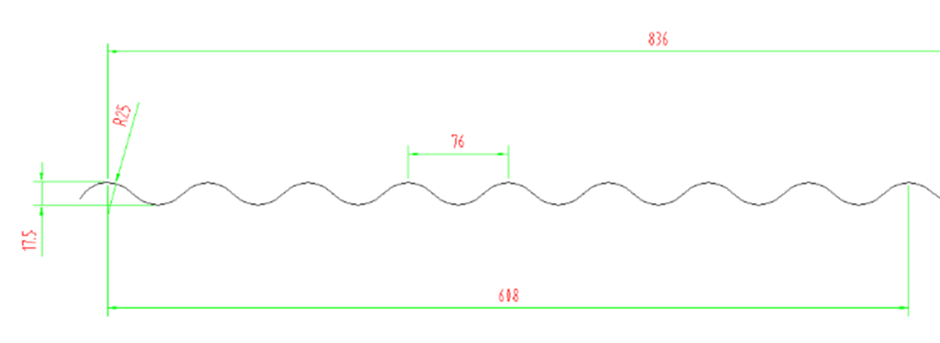

Profile:

Technical specification:

|

Roof panel/Wall panel roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.2-5 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-30 | Or according to your requirement |

|

3 |

Forming station |

18 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

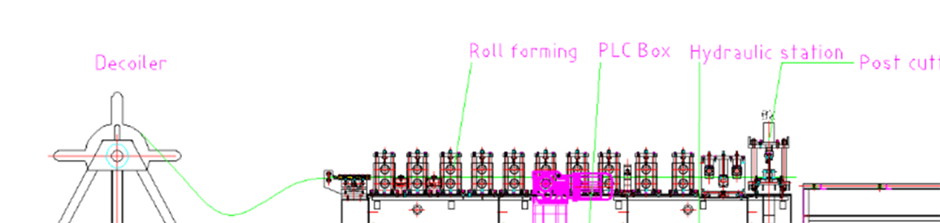

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Understanding Roll Forming Machines

We stick to our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We aim to create more value for our customers with our rich resources, advanced machinery, experienced workers and excellent services for Chinese Professional Customize Supermarket Shelf Panel Machine - Corrugated Panel roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Brasilia, Greenland, Sacramento, So that you can utilize the resource from the expanding info in international trade, we welcome shoppers from everywhere on-line and offline. In spite of the good quality solutions we provide, effective and satisfying consultation service is supplied by our professional after-sale service team. Product lists and detailed parameters and any other info weil be sent to you timely for your inquiries. So you should make contact with us by sending us emails or call us if you have any questions about our corporation. ou may also get our address info from our web page and come to our company to get a field survey of our merchandise. We've been confident that we have been going to share mutual achievement and create strong co-operation relations with our companions in this marketplace. We're searching forward for your inquiries.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.

Send your message to us:

-

Supply ODM Floor Tile Making Machine - Double ...

-

Professional China Pu Sandwich Panel Production...

-

factory low price U Channel Roller Shutter Roll...

-

China Gold Supplier for Sandwich Panel Making M...

-

ODM Supplier Sheet Metal Machine - Gutter roll...

-

Good Wholesale Vendors - Metal Deck roll formi...