Discount wholesale Color Steel Double Layer Machinery - Z Purlin roll forming machine – Linbay Machinery Detail:

Description:

Z Purlin Roll Forming Machine can produce from 100-400mm purlin width . Normally the thickness can be formed at 1.5-3.0 mm. The lips angles can be at 45 or 90 degrees.Regarding the cutting unit ,you can choose the pre-cut or post cut.The driving system we adopt the gimbal or chain drving according to your requirement.We can design the machine as Torri Stand structure or Metal wall structure.

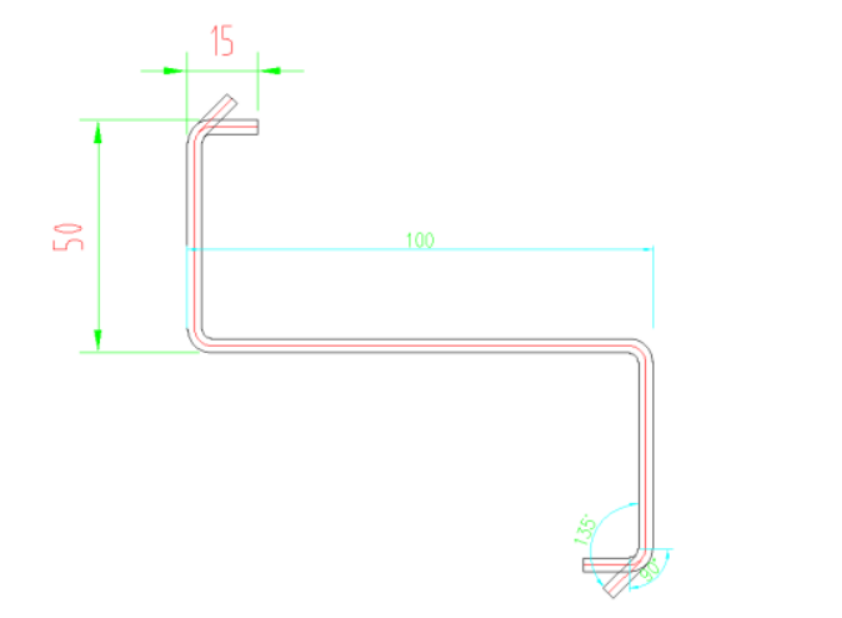

Profile:

Technical specification:

|

Z Purlin roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material | Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-3 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) | 10-25 | Or according to your requirement |

|

3 |

Forming station | 18 | According to your profile |

|

4 |

Decoiler | Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor | Sino-German Brand | Siemens |

|

6 |

PLC brand | Panasonic | Siemens |

|

7 |

Inverter brand | Yaskawa | |

|

8 |

Driving system | Chain drive | Gearbox drive |

|

9 |

Rollers’ materail | Steel #45 | GCr15 |

|

10 |

Station structure | Wall panel station | Forged Iron stationOr torri stand structure |

|

11 |

Punching system | No | Hydraulic punching station or Punching press |

|

12 |

Cutting system | Post-cutting | Pre-cutting |

|

13 |

Power supply requirement | 380V 60Hz | Or according to your requirement |

|

14 |

Machine color | Industrial blue | Or according to your requirement |

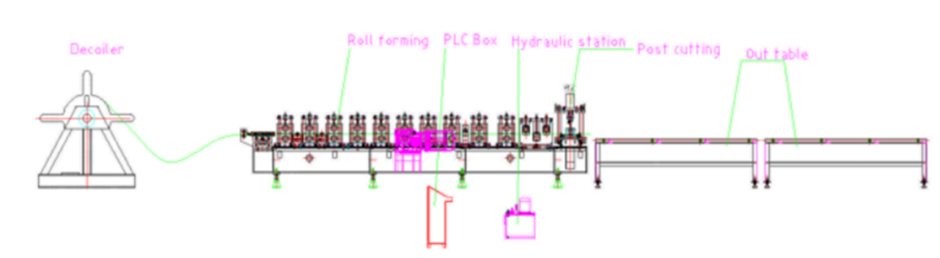

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Roll Forming Machine Design Technology Introduction

The key to our success is "Good Product Excellent, Reasonable Rate and Efficient Service" for Discount wholesale Color Steel Double Layer Machinery - Z Purlin roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Romania, Oman, Thailand, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products for our customers.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.

Send your message to us:

Write your message here and send it to us

-

ODM Supplier Gutter Roll Forming Machine - Doo...

-

Factory Cheap Hot Roofing Arch Sheet Roll Formi...

-

Manufacturer of Screw-joint Machine - Step Bea...

-

Low price for Joint Hidden Machine - Step Beam...

-

Wholesale OEM Double Layer Board Roll Forming M...

-

2018 Good Quality Door Frame Bending Machine Fo...