Discountable price Sheet Metal Bending Machines - Downspout Pipe roll forming machine – Linbay Machinery Detail:

Description:

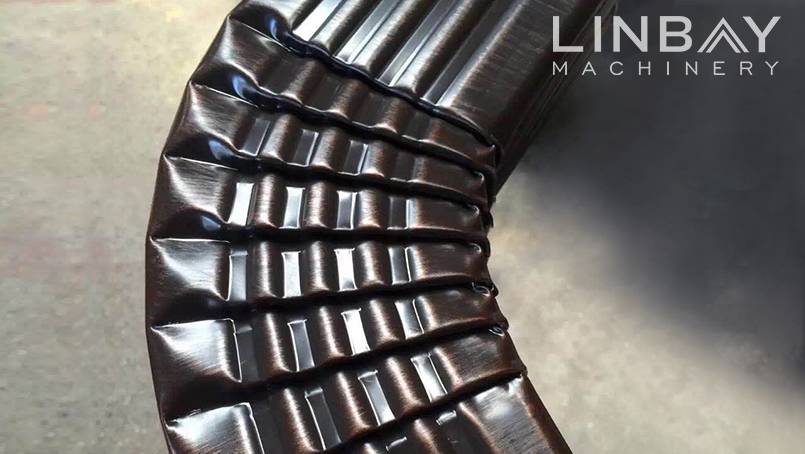

Downspout/Down Pipe Roll Forming Machine can produce the water pipes with perfect surface. It has two types: round pipe and square pipe.

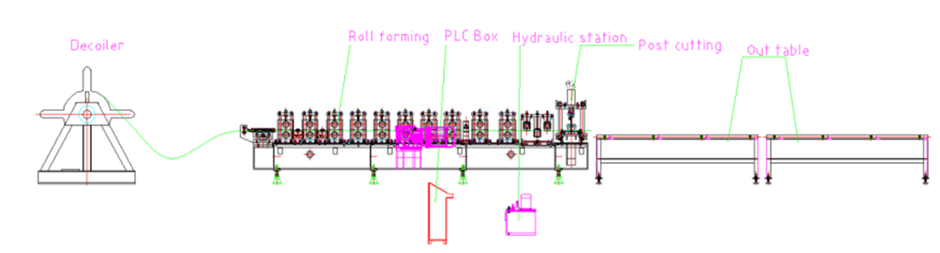

This line include Uncoiler ,Rollforming unit and cutting unit also the Pipe bender unit.

The thickness can be formed Min. 0.3mm thin and Max.2.0mm thick.

The Pipe Bender can be bent the product as 90 degree and retracted for connecting pipe ends.

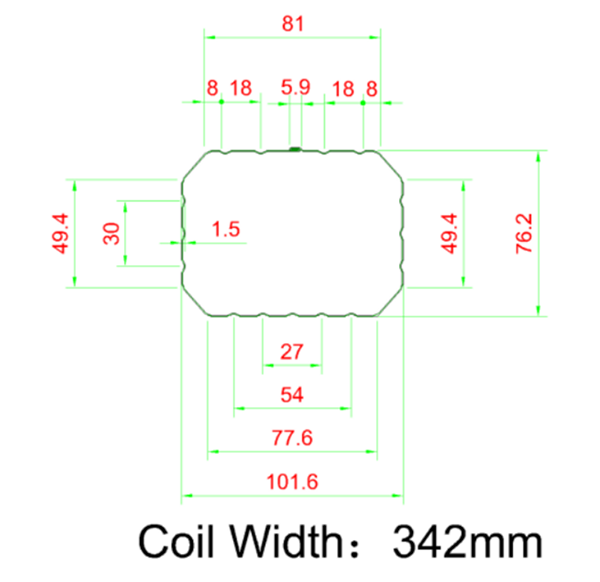

Profile:

Technical specification:

|

Downspout Pipe/Round pipe/ Square pipe roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-2 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

19 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

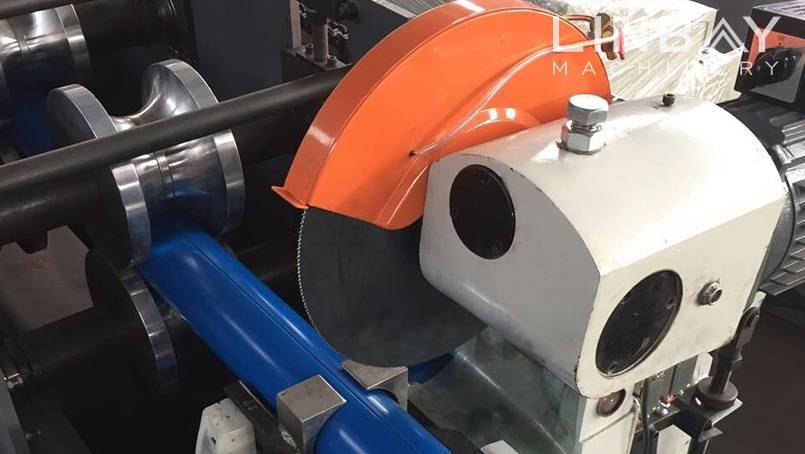

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

Flow Chart:

Product detail pictures:

Related Product Guide:

Roll Forming Machine Design Technology Introduction

Understanding Roll Forming Machines

While using the "Client-Oriented" organization philosophy, a rigorous top quality command process, highly developed production devices and a potent R&D workforce, we normally provide high quality products, outstanding solutions and aggressive charges for Discountable price Sheet Metal Bending Machines - Downspout Pipe roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: USA, Argentina, Palestine, With the enterprising spirit of" high efficiency, convenience, practicality and innovation", and in line with such serving guidance of "good quality but better price, " and "global credit", we are striving to cooperate with the automobile parts companies all over the world to make a win-win partnership.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

Send your message to us:

-

OEM China Door Making Machine - Highway Guardr...

-

Massive Selection for Steel Solar Stent Roll Fo...

-

Reasonable price for Steel Sheet Wall Panel Rol...

-

Good Wholesale Vendors C Z Shape Roll Forming M...

-

Good Quality Studtrack Roll Forming Machine - ...

-

Best Price for Corrugated Panel Roll Forming Ma...