Europe style for Roof Tile Sheet Rolling Forming Machine - Step Beam roll forming machine – Linbay Machinery Detail:

Description:

Square Pipe Roll Forming Machine include Step Beam Roll Formng Machine. Beam rack can both store multi-veriety goods with small quantity and also unified goods with big quantity. And square pipe can be used as down pipe also. Normally thickness can be formed at 1.5-3mm and the speed is about 10-20m/min.This machine is widely used in high warehouses.

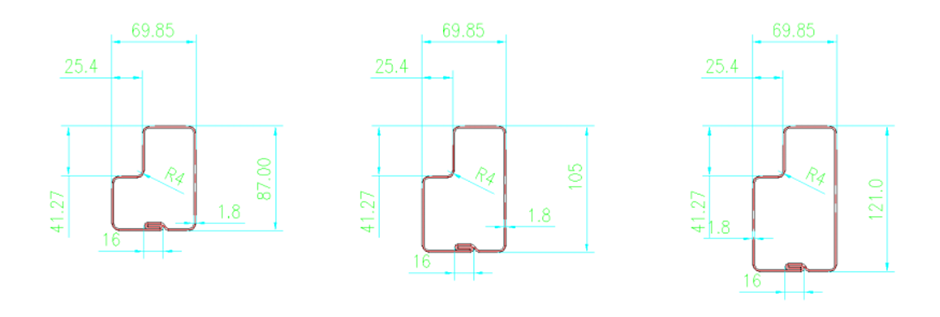

Profile:

Technical specification:

|

Warehouse Step Beam/Square Pipe Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-1.8,1.5-3 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

31 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel station |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

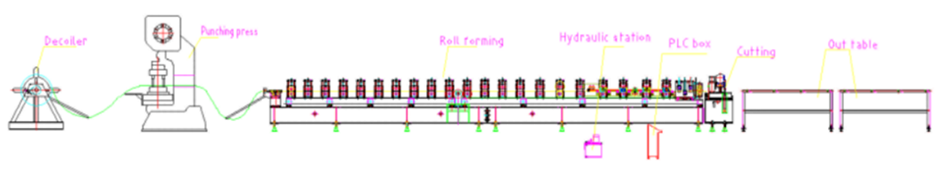

Flow Chart:

Product detail pictures:

Related Product Guide:

Starting and Growing Business With CNC Roll Forming Machine Financing and Leasing

Guide On How To Use a Roll Forming Machine

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs for Europe style for Roof Tile Sheet Rolling Forming Machine - Step Beam roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Wellington, Moscow, Vancouver, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Problems can be quickly and effectively resolved, it is worth to be trust and working together.

Send your message to us:

-

18 Years Factory Double Layer Roll Forming Mach...

-

2018 High quality Solar Panel Machine - Downsp...

-

Super Lowest Price Roof Cold Roll Forming Machi...

-

China Gold Supplier for Building Roll Forming M...

-

OEM Factory for Pu Sandwich Panel Machine - Me...

-

Discountable price Steel Ceiling T Gird Roll Fo...