Factory best selling Double Layer Roll Forming - Z Purlin roll forming machine – Linbay Machinery Detail:

Description:

Z Purlin Roll Forming Machine can produce from 100-400mm purlin width . Normally the thickness can be formed at 1.5-3.0 mm. The lips angles can be at 45 or 90 degrees.Regarding the cutting unit ,you can choose the pre-cut or post cut.The driving system we adopt the gimbal or chain drving according to your requirement.We can design the machine as Torri Stand structure or Metal wall structure.

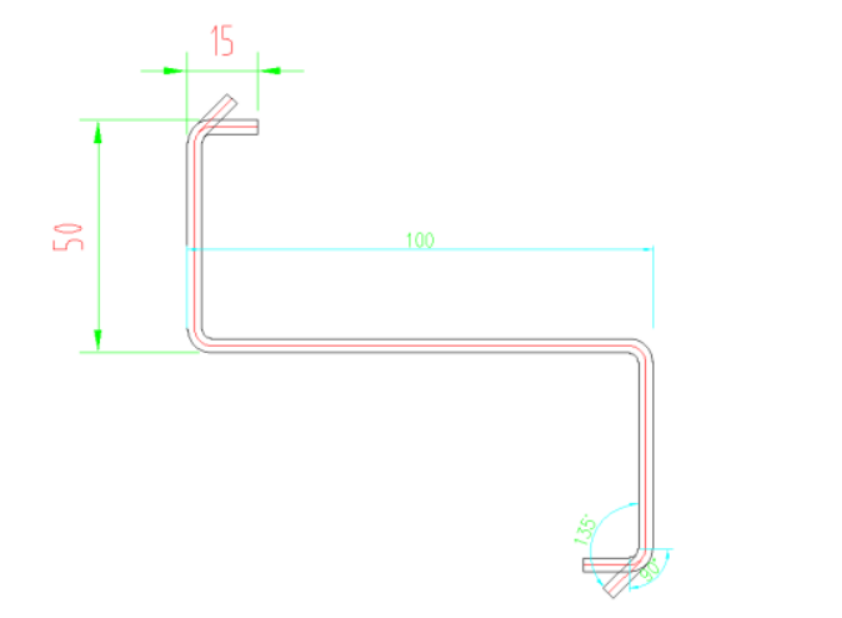

Profile:

Technical specification:

|

Z Purlin roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material | Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-3 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) | 10-25 | Or according to your requirement |

|

3 |

Forming station | 18 | According to your profile |

|

4 |

Decoiler | Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor | Sino-German Brand | Siemens |

|

6 |

PLC brand | Panasonic | Siemens |

|

7 |

Inverter brand | Yaskawa | |

|

8 |

Driving system | Chain drive | Gearbox drive |

|

9 |

Rollers’ materail | Steel #45 | GCr15 |

|

10 |

Station structure | Wall panel station | Forged Iron stationOr torri stand structure |

|

11 |

Punching system | No | Hydraulic punching station or Punching press |

|

12 |

Cutting system | Post-cutting | Pre-cutting |

|

13 |

Power supply requirement | 380V 60Hz | Or according to your requirement |

|

14 |

Machine color | Industrial blue | Or according to your requirement |

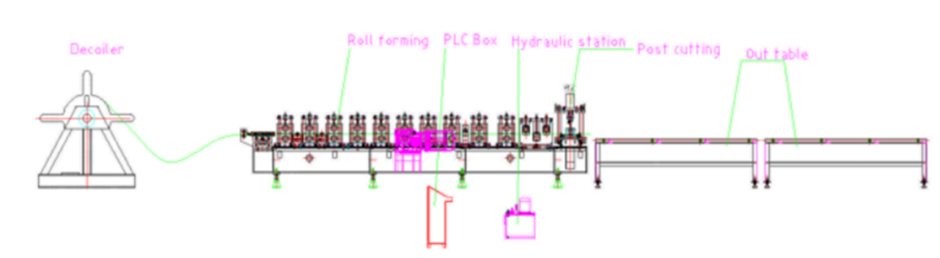

Flow Chart:

Product detail pictures:

Related Product Guide:

Roll Forming Machine Design Technology Introduction

Guide On How To Use a Roll Forming Machine

We've been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for Factory best selling Double Layer Roll Forming - Z Purlin roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: America, Hungary, Finland, We have constructed strong and long co-operation relationship with an enormous quantity of companies within this business in Kenya and overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Kenya for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.

Send your message to us:

Write your message here and send it to us

-

Quality Inspection for Roofing Forming Machine ...

-

Short Lead Time for Aluminium Roof Forming Mach...

-

Supply OEM/ODM Metal Sheet Forming Machine - P...

-

High reputation Automatic Roll Forming Machine ...

-

OEM Manufacturer Zinc Roofing Roll Forming Mach...

-

Popular Design for Steel Tile Forming - Highwa...