Factory For Changeable Z Purlin Roll Forming Machine - Ridge Cap roll forming machine – Linbay Machinery Detail:

Description:

This Ridge Cap roll forming machine is used in roofing sheet. The normal raw material is 0.3-0.8mm thickness. Normal working speed is 10-25m/min. It has many different shapes, we can make all kinds of machine if you can offer the profile to us. We are very profesional in OEM roll forming machine.

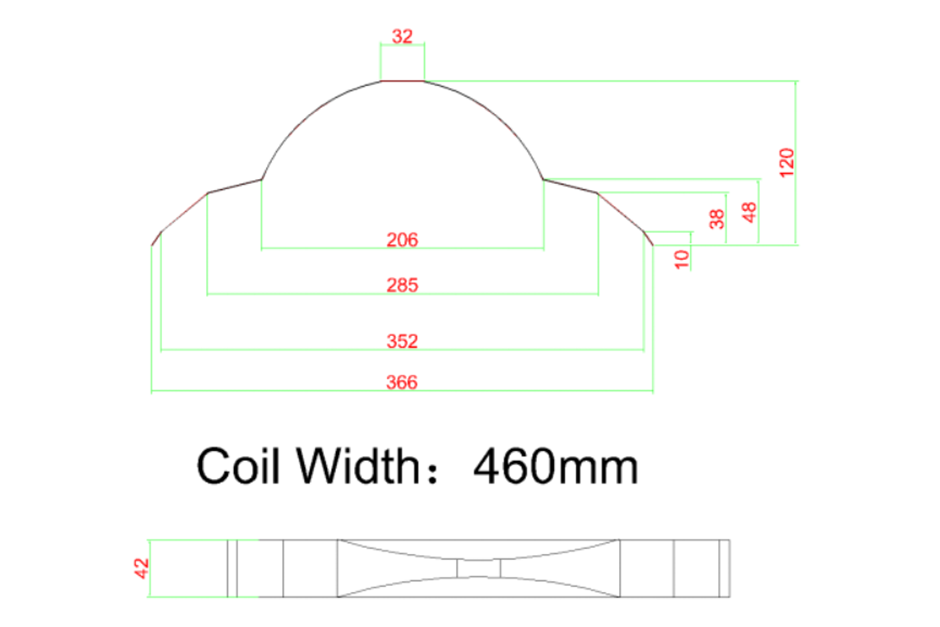

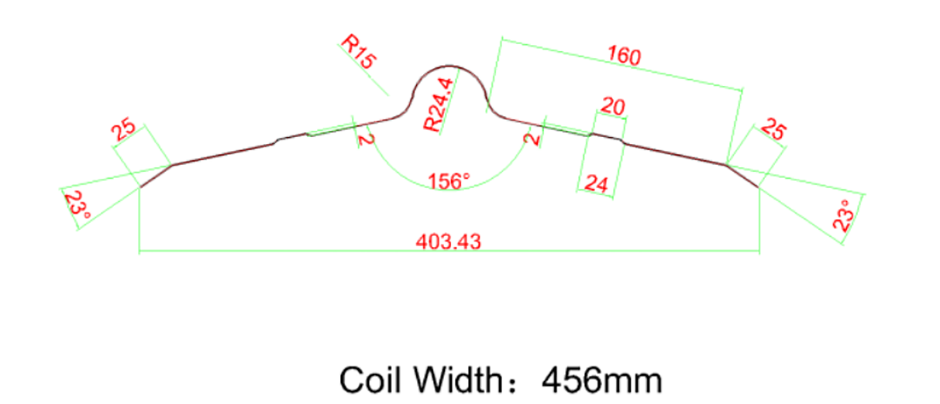

Profile:

Technical specification:

|

Ridge cap roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.3-0.8 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

14 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

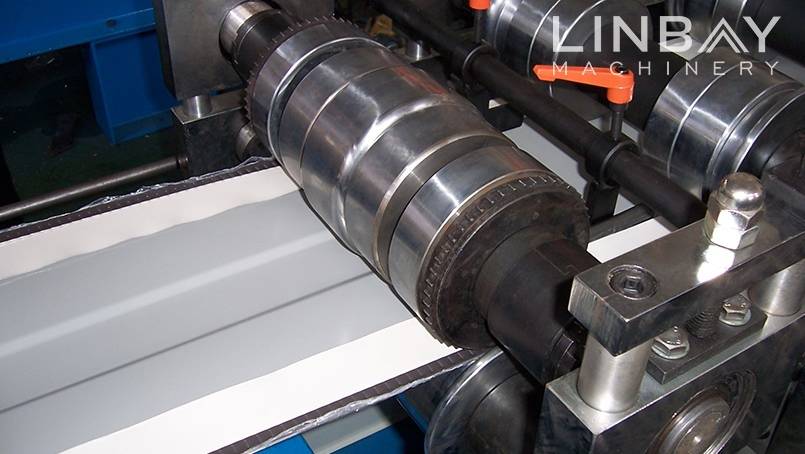

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

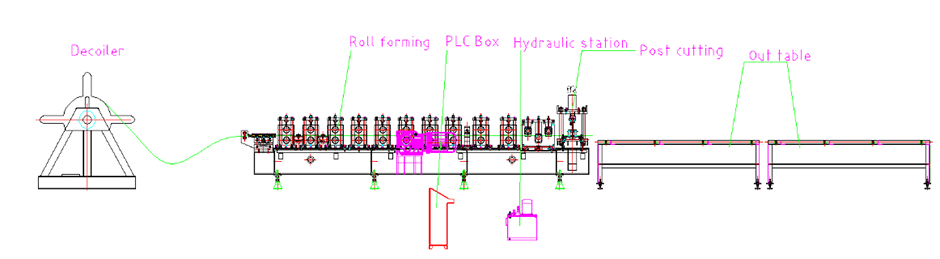

Flow Chart:

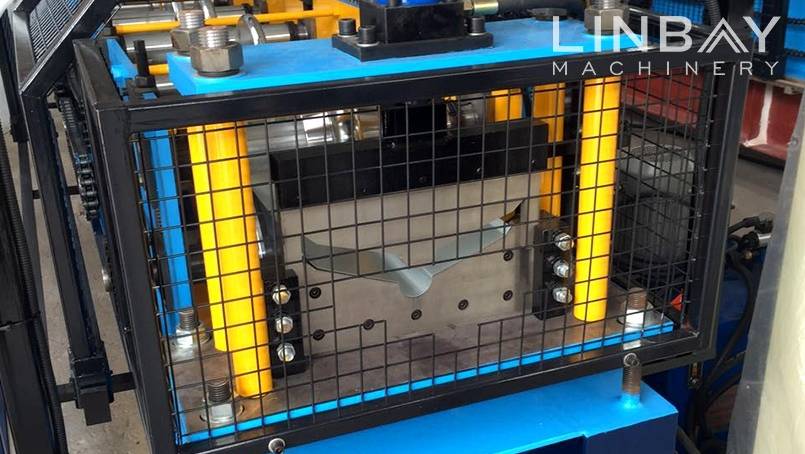

Product detail pictures:

Related Product Guide:

Understanding Roll Forming Machines

Guide On How To Use a Roll Forming Machine

We're commitment to offer you the aggressive cost ,superb products and solutions top quality, too as fast delivery for Factory For Changeable Z Purlin Roll Forming Machine - Ridge Cap roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Peru, Ghana, Amsterdam, Our advanced equipment, excellent quality management, research and development ability make our price down. The price we offering may not be the lowest, but we guarantee it is absolutely competitive! Welcome to contact us immediately for future business relationship and mutual success!

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!

Send your message to us:

-

Top Grade Metal Sheet Rolling Machine - Gutter...

-

Discountable price Corrugated Roofing - Suspen...

-

OEM/ODM Supplier Steel Roof Forming Machine - ...

-

Wholesale OEM/ODM Roofing Sheets Machine - Str...

-

factory Outlets for Used Steel Pipe Making Mach...

-

Massive Selection for Steel Solar Stent Roll Fo...