Factory For Changeable Z Purlin Roll Forming Machine - Strut and Rail roll forming machine – Linbay Machinery Detail:

Description:

Steel Strut&Rail Roll Fomring Machine includ Door Rail Roll Fomring Machine, Steel C Channel Roll Forming Machine, Solar Rack Roll Forming Machine etc. The working thickness can be 1.5-2.5mm. The Max. working speed can be 25m/min. We adopt gearbox driving system to keep our machine work with high speed and prolong the service life.

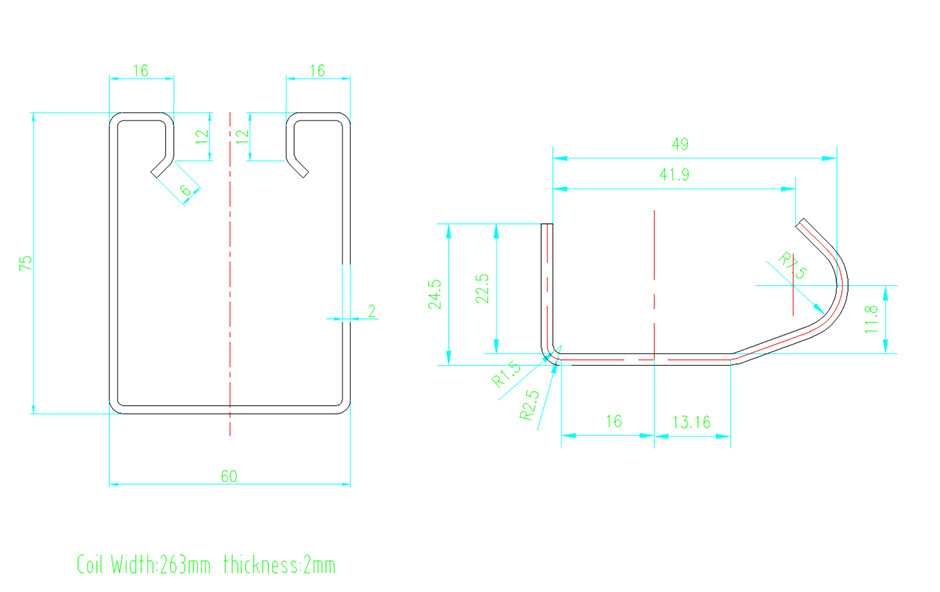

Profile:

Technical specification:

|

Steel Strut& Rail roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-2.5 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

17 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Gearbox drive | Chain drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

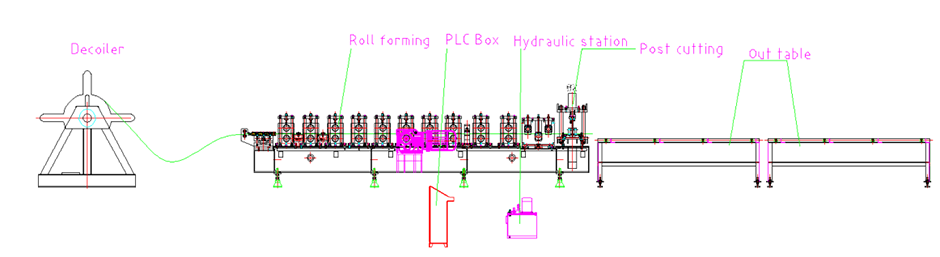

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Starting and Growing Business With CNC Roll Forming Machine Financing and Leasing

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for Factory For Changeable Z Purlin Roll Forming Machine - Strut and Rail roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Rome, Italy, United Arab emirates, With the development and enlargement of mass clients abroad, now we've set up cooperative relationships with many major brands. We've our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost items and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!

Send your message to us:

-

Short Lead Time for C Channel Roll Forming Mach...

-

Fixed Competitive Price Aluzinc Roof Forming Ma...

-

2018 wholesale price Roof T Forming Machine - ...

-

Factory Supply Galvanized Steel Sheet Metal Sta...

-

Wholesale Price China Tile Machine - C Z Purli...

-

Wholesale Price High Quality Roof Forming Machi...