Factory made hot-sale Double Layer Roll Forming Machine - Gutter roll forming machine – Linbay Machinery Detail:

Description:

Gutter Roll Forming Machine normally work with 0.4-0.6mm thickness raw material to make gutters and drains. Normal working speed is aroun 10-20m/min. We adopt torri stand structure, it’s more beautiful and more table when the machine working.

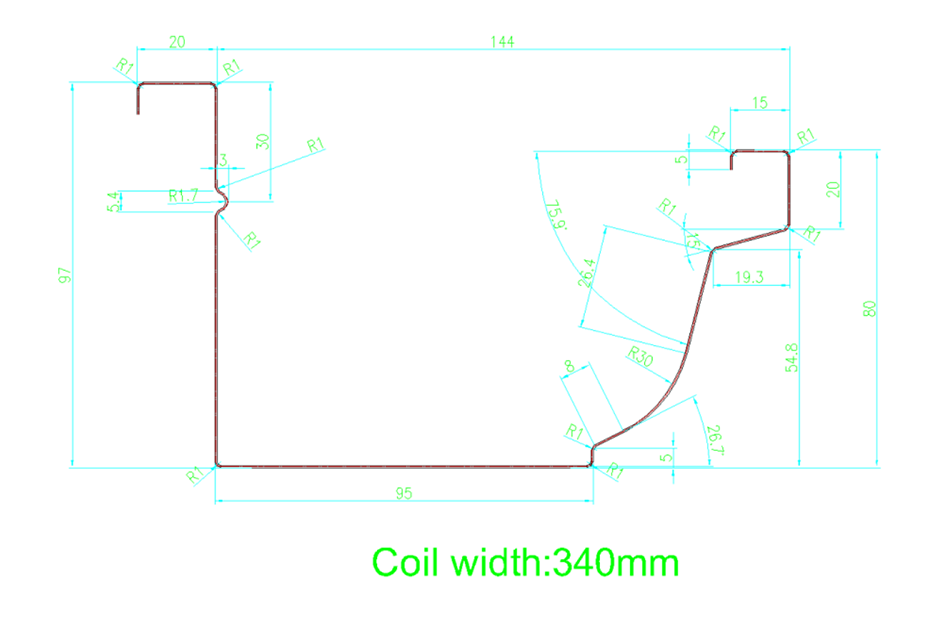

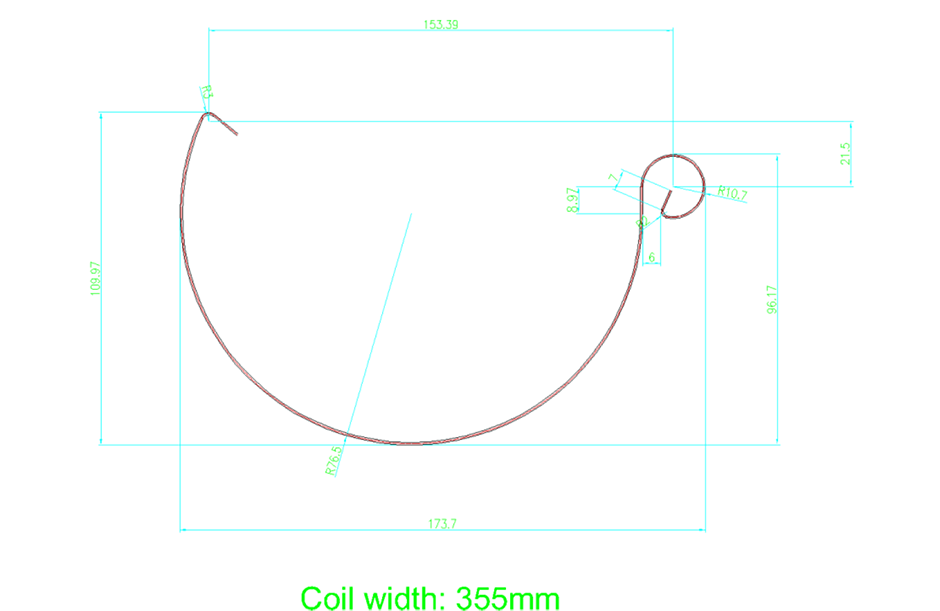

Profile:

Technical specification:

|

Gutter roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.4-0.6 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

19 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

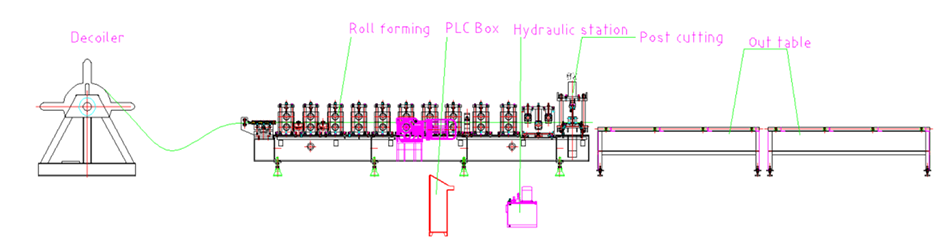

Flow Chart:

Product detail pictures:

Related Product Guide:

Roll Forming Machine Design Technology Introduction

Cold Roll Forming Machines – New Army in Steel Construction Industry

Good quality comes 1st; assistance is foremost; business enterprise is cooperation" is our business enterprise philosophy which is regularly observed and pursued by our company for Factory made hot-sale Double Layer Roll Forming Machine - Gutter roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Georgia, Philippines, Mauritius, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound solutions with good logistics service and economical cost. Depending on this, our solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!

Send your message to us:

Write your message here and send it to us

-

Professional Factory for Metal Sheet Roofing Ti...

-

OEM/ODM Manufacturer Z Purlin Roll Forming Mach...

-

Free sample for Corrugated Roof Roll Forming Ma...

-

China Supplier Steel Floor Decking Forming Mach...

-

Good Quality Steel Profile Roll Forming Machine...

-

Excellent quality Roller Shutters Slats Machine...