Factory Price For Corrugated Roofing Tile Roll Forming Machine - Gutter roll forming machine – Linbay Machinery Detail:

Description:

Gutter Roll Forming Machine normally work with 0.4-0.6mm thickness raw material to make gutters and drains. Normal working speed is aroun 10-20m/min. We adopt torri stand structure, it’s more beautiful and more table when the machine working.

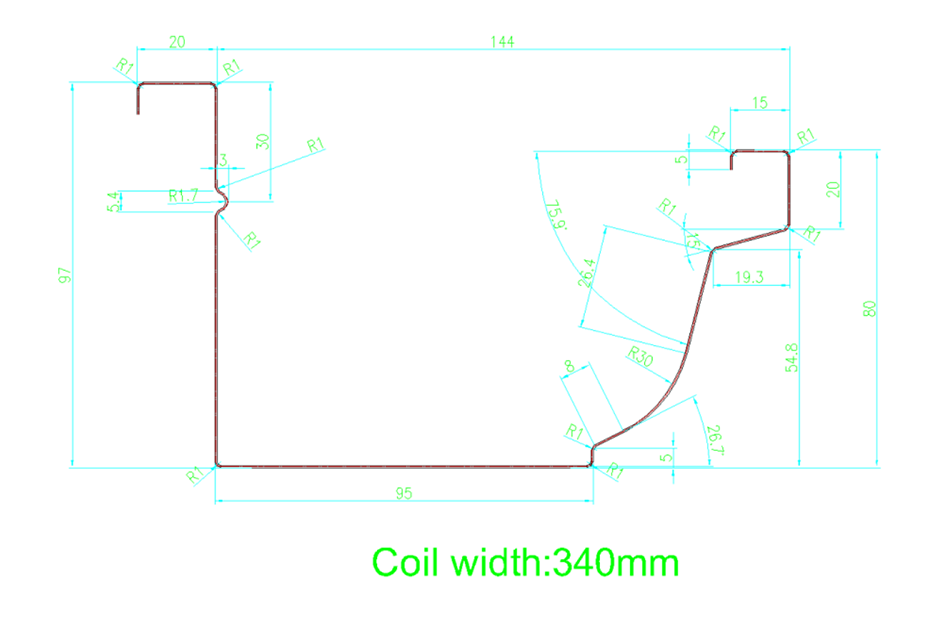

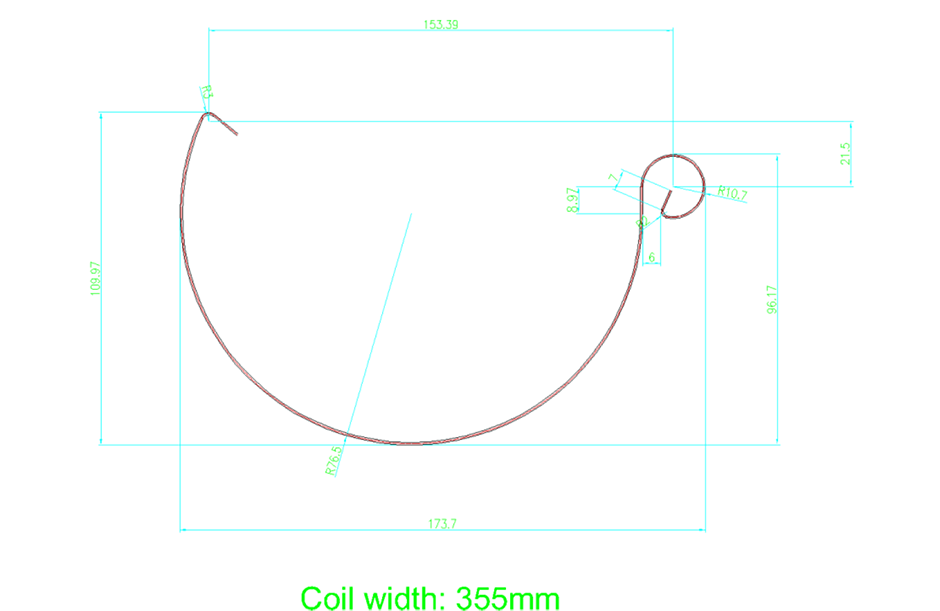

Profile:

Technical specification:

|

Gutter roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.4-0.6 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

19 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

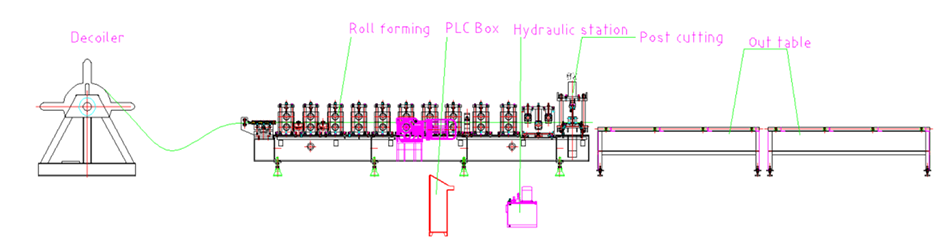

Flow Chart:

Product detail pictures:

Related Product Guide:

Starting and Growing Business With CNC Roll Forming Machine Financing and Leasing

Guide On How To Use a Roll Forming Machine

High quality Initial,and Buyer Supreme is our guideline to offer the ideal assistance to our shoppers.At present, we are striving our best to become amongst the ideal exporters inside our industry to satisfy shoppers more want for Factory Price For Corrugated Roofing Tile Roll Forming Machine - Gutter roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Zurich, Madras, Bahrain, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.

Send your message to us:

Write your message here and send it to us

-

Factory made hot-sale Automatic C Purlin Channe...

-

Wholesale Dealers of Steel Roofing Roll Forming...

-

Renewable Design for Glazed Tiles Roll Forming ...

-

Professional China Price Matel Roofing Sheet Ar...

-

OEM Customized Double Deck Metal Roofing Roll F...

-

2018 New Style C Channel Forming Machine - Dow...