Factory source Double Layer Forming Machine - Metal Deck roll forming machine – Linbay Machinery Detail:

Description:

Metal deck steel produced by this Metal Deck Roll Forming Machine, it has high strength with big wave length .It not only save steel mold plate but also reduce the weight of the storey.

We made Max. 153mm heigh profile drawings. Normally the material thickness is from 0.6-1.2mm.

This machine we also can design it as a Cassette Type.

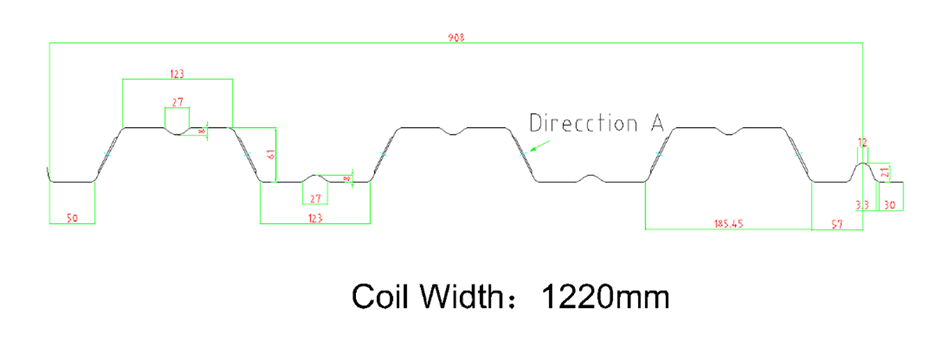

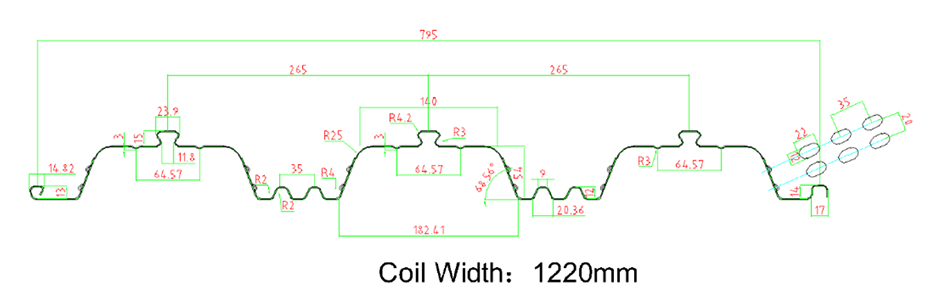

Profile:

Technical specification:

|

Metal deck roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.6-3 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

26 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

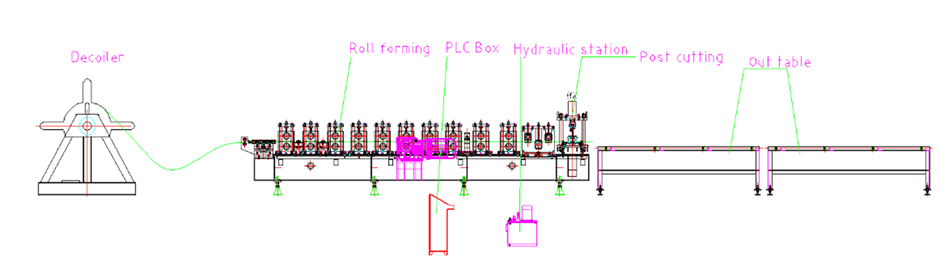

Flow Chart:

Product detail pictures:

Related Product Guide:

Cold Roll Forming Machines – New Army in Steel Construction Industry

Understanding Roll Forming Machines

Reliable quality and good credit standing are our principles, which will help us at a top-ranking position. Adhering to the tenet of "quality first, customer supreme" for Factory source Double Layer Forming Machine - Metal Deck roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Malta, Seychelles, Morocco, Why we can do these? Because: A, We are honest and reliable. Our products have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It will be highly appreciated.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

Send your message to us:

-

Europe style for Ceiling Battens Forming Machin...

-

ODM Manufacturer Aluminum Roll Forming Machine ...

-

Short Lead Time for Roof Tile Ridge Roll Formin...

-

China OEM Pu Sandwich Panel Production Line - ...

-

China Factory for Full Automatic Fast Change C/...

-

2018 New Style Roofing Sheet Roll Forming Machi...