Free sample for Cold Roll Former Machinery - Gutter roll forming machine – Linbay Machinery Detail:

Description:

Gutter Roll Forming Machine normally work with 0.4-0.6mm thickness raw material to make gutters and drains. Normal working speed is aroun 10-20m/min. We adopt torri stand structure, it’s more beautiful and more table when the machine working.

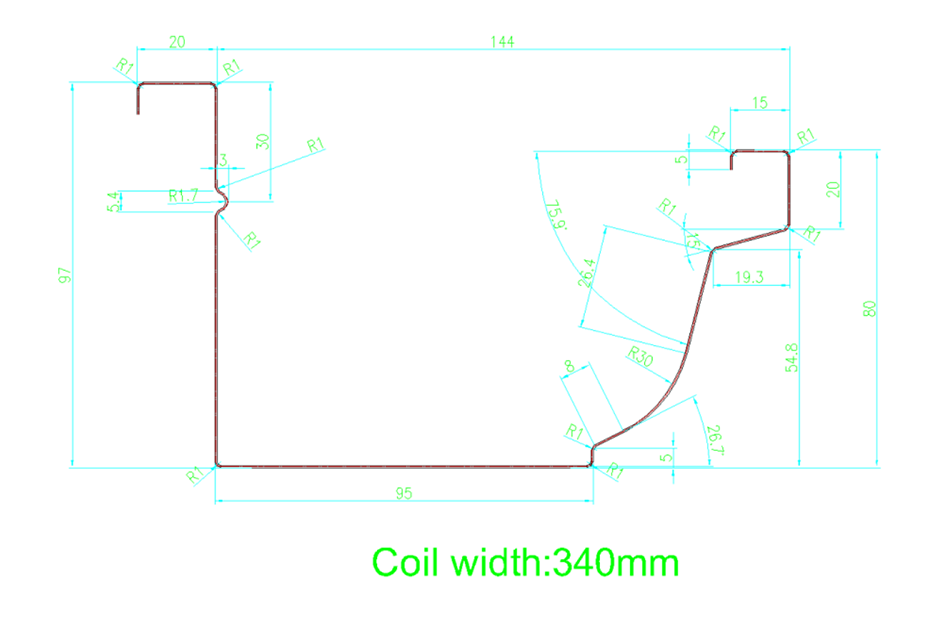

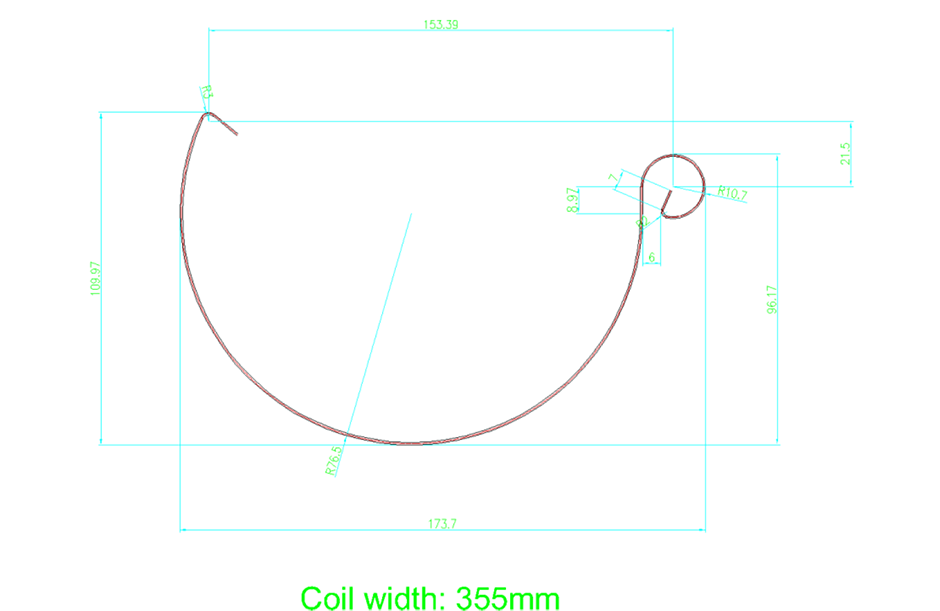

Profile:

Technical specification:

|

Gutter roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.4-0.6 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

19 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

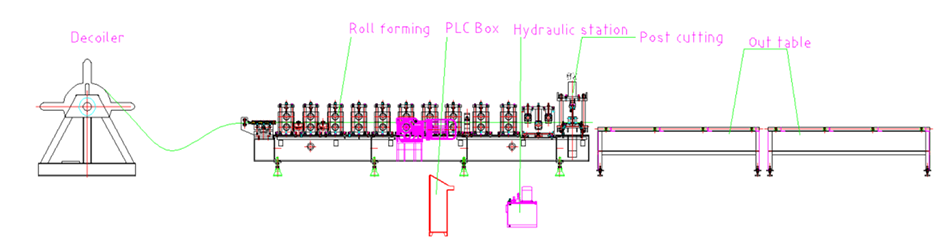

Flow Chart:

Product detail pictures:

Related Product Guide:

Understanding Roll Forming Machines

Cold Roll Forming Machines – New Army in Steel Construction Industry

With a positive and progressive attitude to customer's interest, our enterprise continually improves our products excellent to meet the wants of customers and further focuses on safety, reliability, environmental requirements, and innovation of Free sample for Cold Roll Former Machinery - Gutter roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Mexico, Portugal, Manchester, We have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we are looking forward to even greater cooperation with overseas customers based on mutual benefits. Please feel free to contact us for more details.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!

Send your message to us:

Write your message here and send it to us

-

China wholesale Corrugated Machine Price - Cab...

-

Cheapest Price Deck Floor Roll Forming Machine ...

-

2018 China New Design Shelf Rack Roll Forming M...

-

Excellent quality Sandwich Roof Tile Machine -...

-

China Gold Supplier for Cable Tray Forming Mach...

-

OEM Supply Roof Tile Panel Roll Forming Machine...