Good Quality Roll Forming Machine - Double Layer Panel roll forming machine – Linbay Machinery Detail:

Description:

Double Layer Roll Forming Machine can produce two different profile drawings in one machine, it can save more room and of course more economy compared with two different machines.

You can choose two different kind of profile drawings as well as corrugated sheet drawing, but one time only can produce one layer profile . There is one clutch as one side of the machine, and we just need simply to move one handle wheel to make other layer profile.

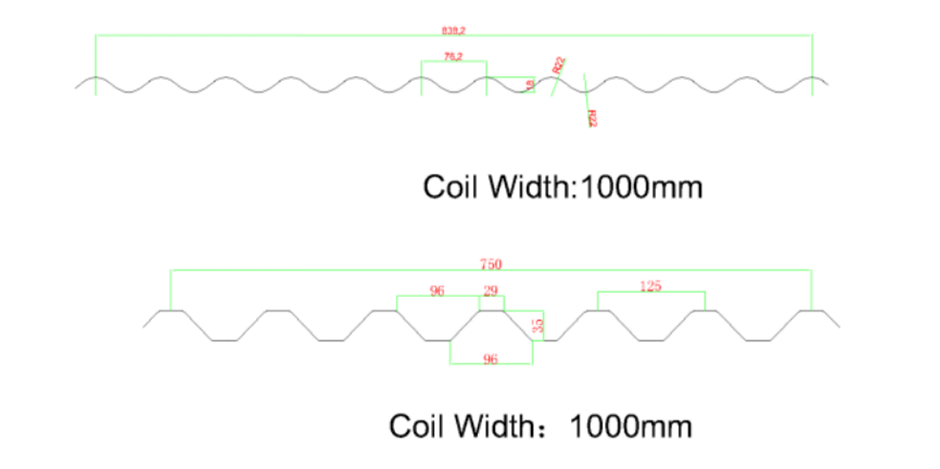

Profile:

Technical specification:

|

Double Layer Corrugated sheet roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.3-0.8 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

20-23 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

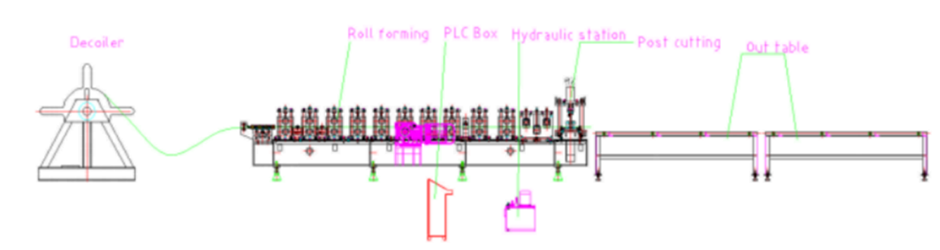

Flow Chart:

Product detail pictures:

Related Product Guide:

Roll Forming Machine Design Technology Introduction

Understanding Roll Forming Machines

Our business sticks for the basic principle of "Quality could be the life with the firm, and track record will be the soul of it" for Good Quality Roll Forming Machine - Double Layer Panel roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Nicaragua, Armenia, European, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, please feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our products, please feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.

Send your message to us:

-

Special Price for Keel Cold Roll Forming Machin...

-

Bottom price Wall/roof Panel Forming Machine -...

-

Factory best selling Downspout Roll Forming Mac...

-

Factory Cheap Aluminium Roofing Sheet Making Ma...

-

Professional Design Single Layer Roof Sheet Mac...

-

Best Price on Ridge Tile Forming Machine - Dow...