High definition Seam Lock Roofing Roll Forming Machine - Rolling Shutter Slat roll forming machine – Linbay Machinery Detail:

Description:

Roller Shutter Door Roll Forming Machine produce stainless steel rolling shutter doors and color steel rolling shutter doors. We use punching press to make different hollow-carved designs. If you ask, we can also produce PU Rolling Shutter Door Roll Forming Machine, which machine can make fire resistance and thermal insulation rolling shutter doors.

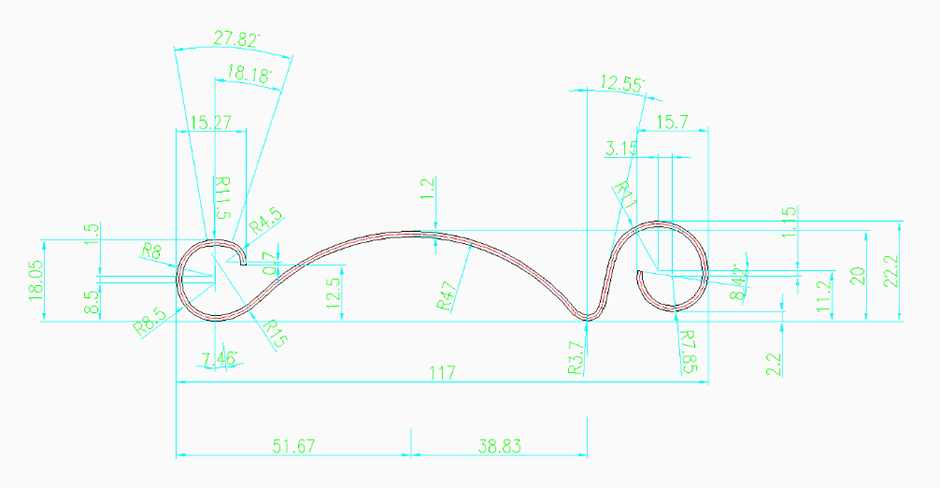

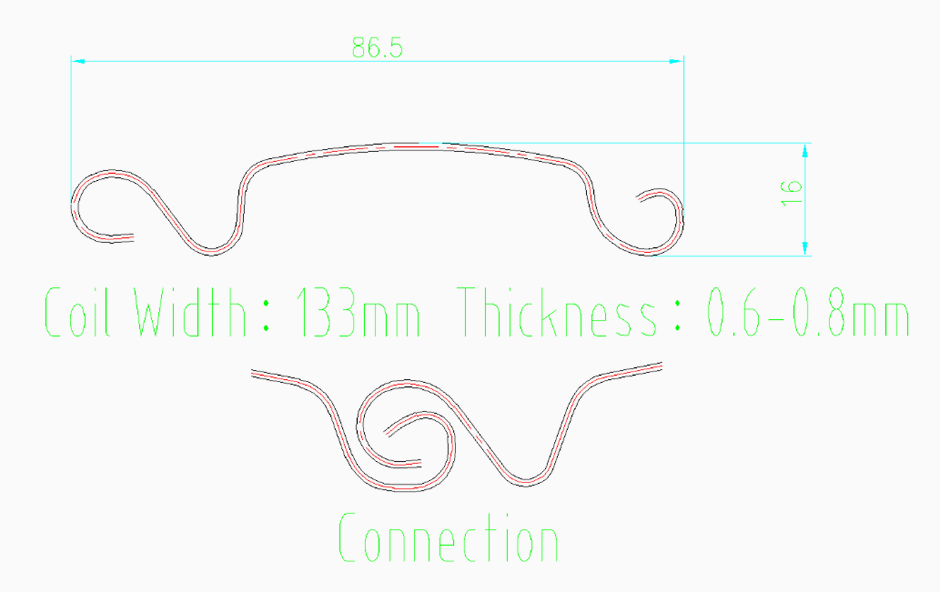

Profile:

Technical specification:

|

Roller Shutter Door roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.0-2.0 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

17 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

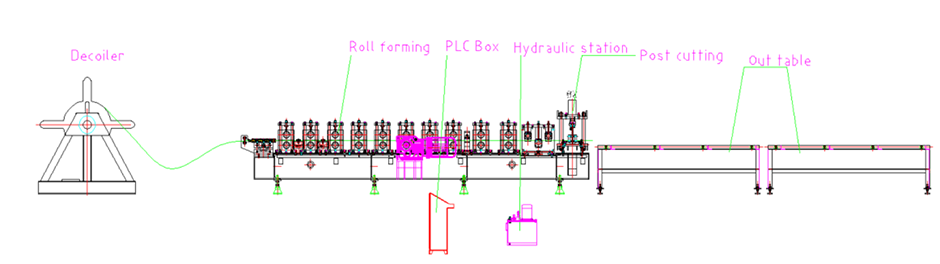

Flow Chart:

Product detail pictures:

Related Product Guide:

Understanding Roll Forming Machines

Cold Roll Forming Machines – New Army in Steel Construction Industry

Our target is always to satisfy our customers by offering golden support, superior value and high quality for High definition Seam Lock Roofing Roll Forming Machine - Rolling Shutter Slat roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: London, Yemen, Sevilla, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question items they do not understand. We break down people barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.

Send your message to us:

-

Factory wholesale Rock Wool Panel Production Li...

-

OEM Factory for Step Tile Roof Profile Roll For...

-

ODM Supplier Corrugating Sheet Making Machine -...

-

China wholesale Professional Roll Forming Machi...

-

China OEM Roll Form Machin - Stud and Track ro...

-

Discount wholesale Roofing Panel Machine - Rid...