High Quality for Roof Sheet Glazed Tiles Roll Forming Machine - Gutter roll forming machine – Linbay Machinery Detail:

Description:

Gutter Roll Forming Machine normally work with 0.4-0.6mm thickness raw material to make gutters and drains. Normal working speed is aroun 10-20m/min. We adopt torri stand structure, it’s more beautiful and more table when the machine working.

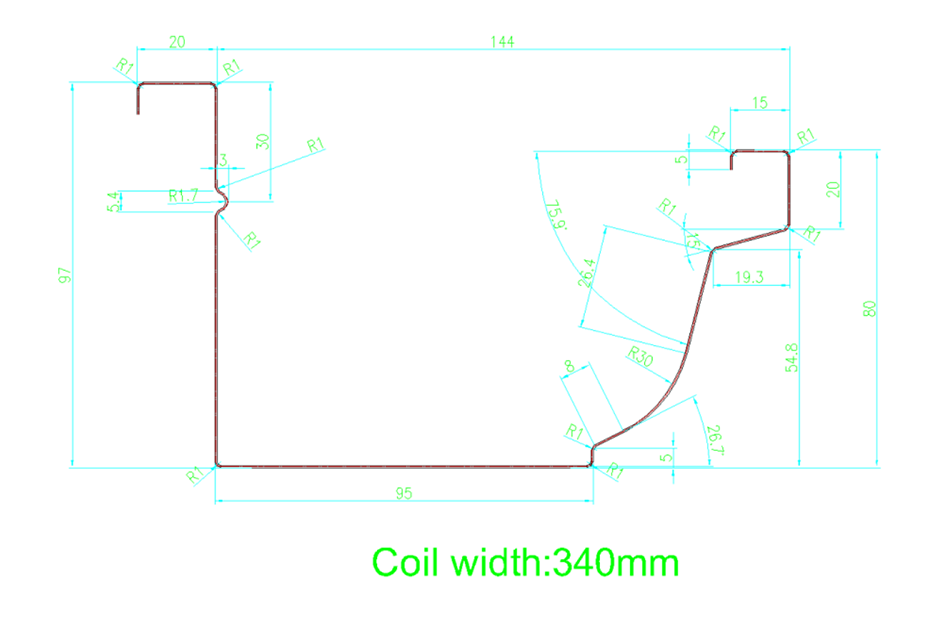

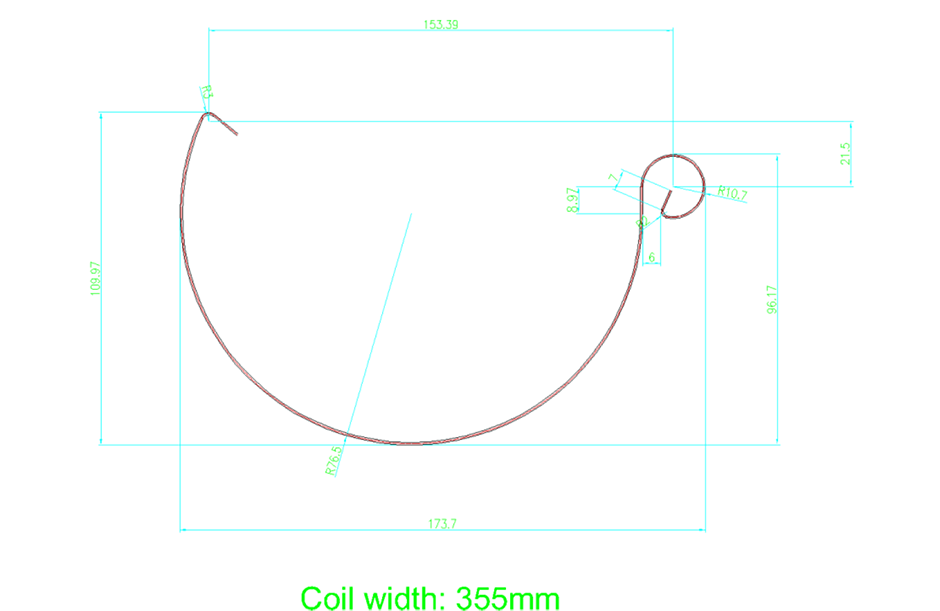

Profile:

Technical specification:

|

Gutter roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.4-0.6 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

19 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

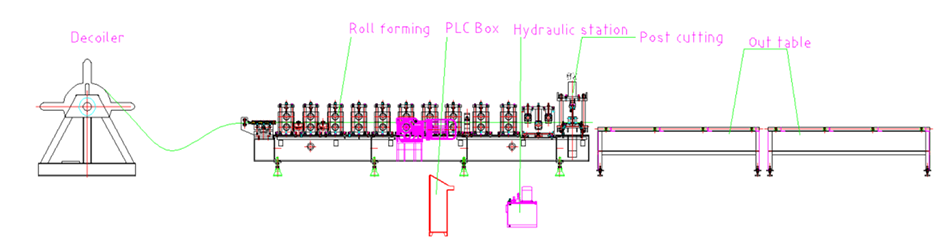

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Understanding Roll Forming Machines

It is actually our accountability to satisfy your needs and effectively serve you. Your pleasure is our best reward. We're on the lookout forward for your stop by for joint growth for High Quality for Roof Sheet Glazed Tiles Roll Forming Machine - Gutter roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Chile, Grenada, St. Petersburg, We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our products are favored by domestic and foreign customers. With your support, we will build a better tomorrow!

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!

Send your message to us:

Write your message here and send it to us

-

factory low price Roll Forming Machine Price -...

-

China OEM German Roof Tile Roll Forming Machine...

-

Hot Selling for Galvanized Ridge Cap Zinc Roofi...

-

Wholesale Dealers of T Roll Machine - Highway ...

-

2018 China New Design Rainwater Gutter Machine ...

-

New Arrival China Roof Forming Machine - Ridge...