High Quality Sandwich Wall Panel Insulation Pannel - Metal Deck roll forming machine – Linbay Machinery Detail:

Description:

Metal deck steel produced by this Metal Deck Roll Forming Machine, it has high strength with big wave length .It not only save steel mold plate but also reduce the weight of the storey.

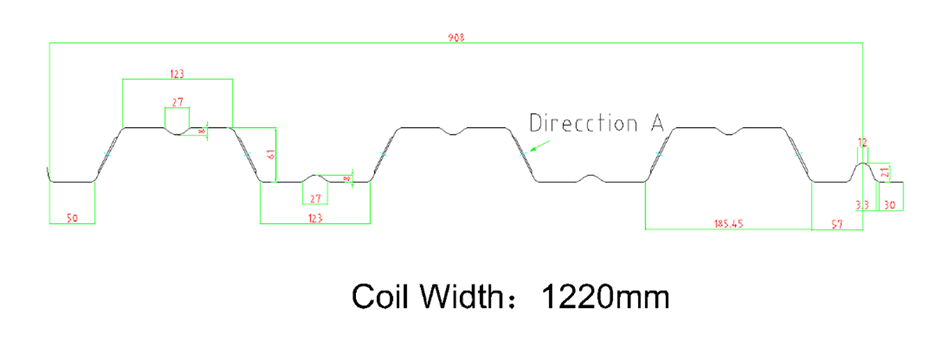

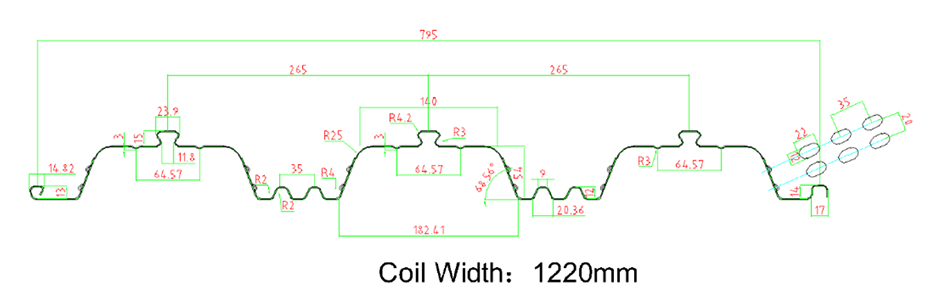

We made Max. 153mm heigh profile drawings. Normally the material thickness is from 0.6-1.2mm.

This machine we also can design it as a Cassette Type.

Profile:

Technical specification:

|

Metal deck roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.6-3 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

26 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

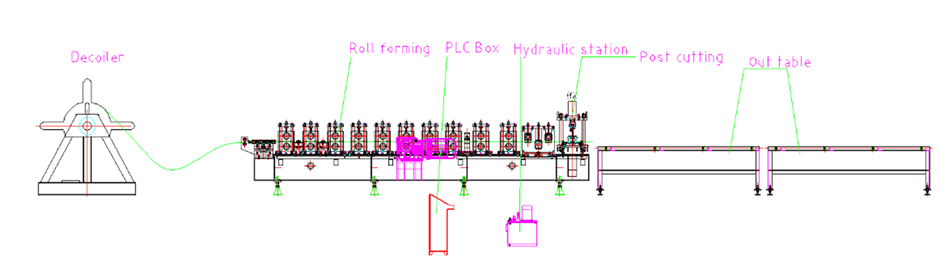

Flow Chart:

Product detail pictures:

Related Product Guide:

Understanding Roll Forming Machines

Roll Forming Machine Design Technology Introduction

We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for High Quality Sandwich Wall Panel Insulation Pannel - Metal Deck roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: United States, Ghana, Malaysia, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our items have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.

Send your message to us:

-

Hot Selling for Custom Steel Roll Former - Dow...

-

Best-Selling Shelf Roll Forming Machine - Roof...

-

Factory made hot-sale Automatic C Purlin Channe...

-

Supply ODM Floor Tile Making Machine - Ridge C...

-

Discountable price Sheet Metal Bending Machines...

-

Factory Cheap Track Roll Forming Machine - PU ...