High reputation Automatic Stud And Track Roll Forming Machine - Strut and Rail roll forming machine – Linbay Machinery Detail:

Description:

Steel Strut&Rail Roll Fomring Machine includ Door Rail Roll Fomring Machine, Steel C Channel Roll Forming Machine, Solar Rack Roll Forming Machine etc. The working thickness can be 1.5-2.5mm. The Max. working speed can be 25m/min. We adopt gearbox driving system to keep our machine work with high speed and prolong the service life.

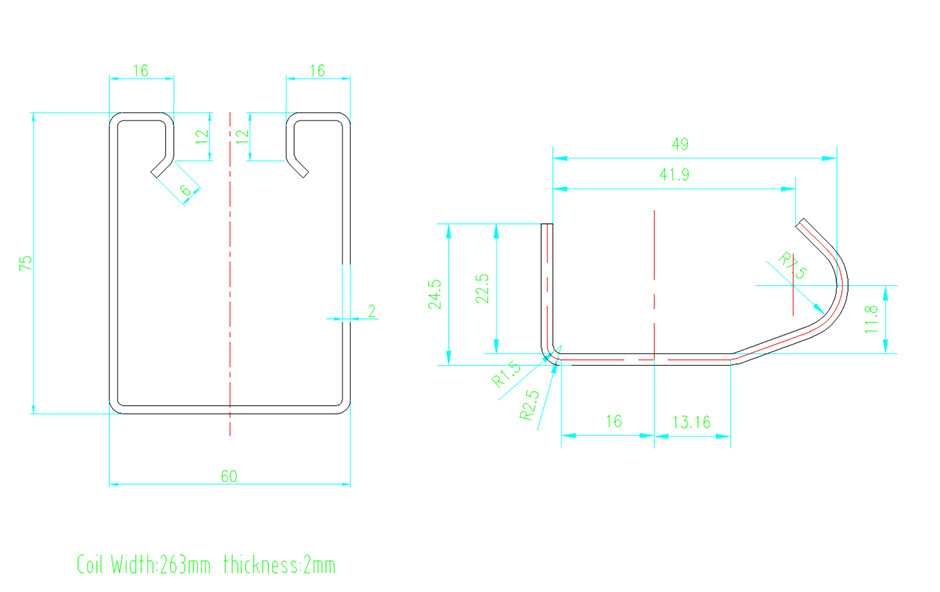

Profile:

Technical specification:

|

Steel Strut& Rail roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-2.5 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

17 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Gearbox drive | Chain drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

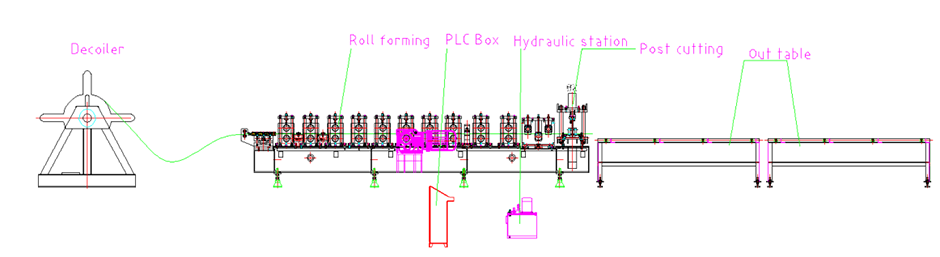

Flow Chart:

Product detail pictures:

Related Product Guide:

Roll Forming Machine Design Technology Introduction

Understanding Roll Forming Machines

Being supported by an highly developed and specialist IT team, we could give technical support on pre-sales & after-sales service for High reputation Automatic Stud And Track Roll Forming Machine - Strut and Rail roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Uganda, Romania, Saudi Arabia, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products and solutions for our customers.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

Send your message to us:

-

Massive Selection for Guard Rail Highway Guardr...

-

Factory For Roofing Corrugated Tile Forming Mac...

-

Quality Inspection for C And Z Shape Machine -...

-

Manufacturer of T Steel Keel Machine - C Purli...

-

Wholesale Glazed Double Layer Roll Forming Mach...

-

8 Years Exporter Scaffolding Roll Forming Machi...