Manufactur standard Customized Working Platform - C Purlin roll forming machine – Linbay Machinery Detail:

Description:

This C/U Purlin Roll Forming Machine, can produce C shape and U shape purlins from 100-400mm of width and easily to change spacers. Maximum thickness can be formed at 4.0-6.0mm.

Also we can design this machine to work with any width of the purlins and main channels, automatically adjustable by PLC control or adjust handle wheel to change the sheet width. This is much more easily than adjust the spacers and can save more time. Regarding the cutting unit ,you can choose the pre-cut or post cut.The driving system we adopt the gimbal system if the raw material is thicker than 2.5mm,this is much more strong driving power and more stable when forming the purlins.

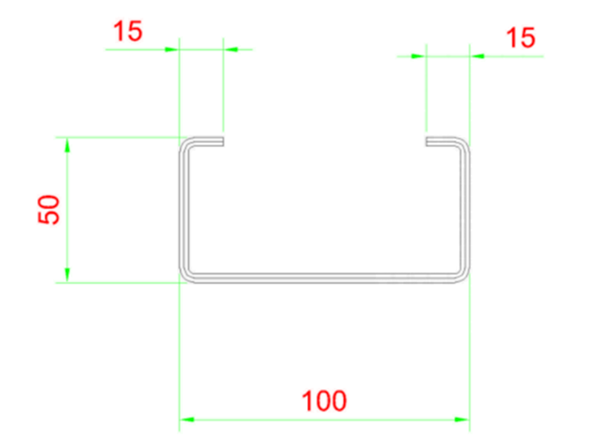

Profile:

Technical specification:

|

C/U Purlin roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.4-0.6, 1.5-3, 4-6 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

According to your profile | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron stationOr torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

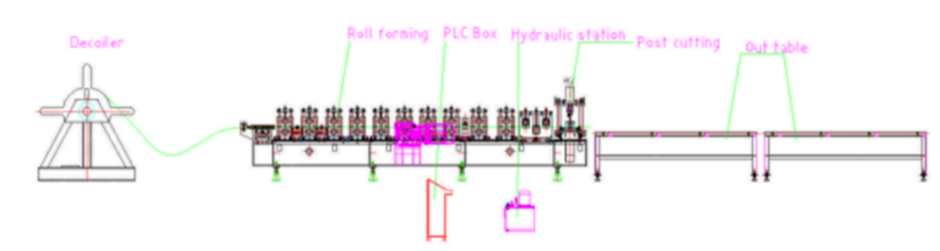

Flow Chart:

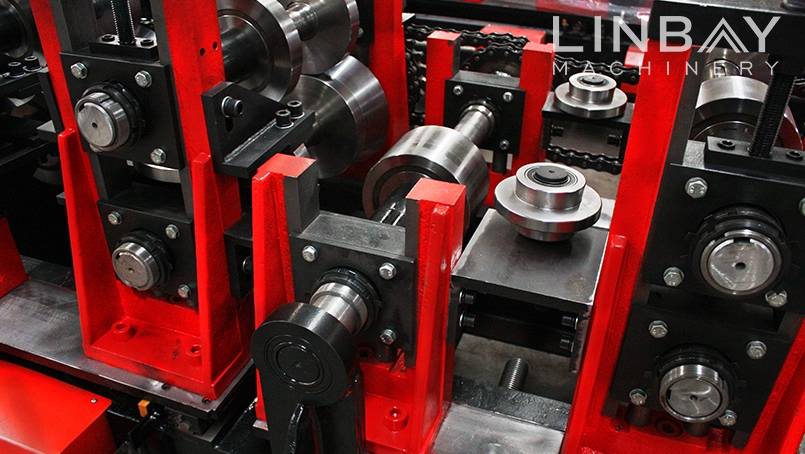

Product detail pictures:

Related Product Guide:

Roll Forming Machine Design Technology Introduction

Guide On How To Use a Roll Forming Machine

Every single member from our large efficiency profits team values customers' requirements and organization communication for Manufactur standard Customized Working Platform - C Purlin roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Libya, Uganda, Singapore, Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.

Send your message to us:

-

Factory source Light Weight Roll Foming Machine...

-

Fixed Competitive Price Panel Tile Roll Forming...

-

China Supplier Semi Circle Gutter Forming Machi...

-

Professional Design Single Layer Roof Sheet Mac...

-

Bottom price Square Pipe Roll Forming Machine -...

-

Big discounting C Shape Purlin Roll Forming Mac...