Manufactur standard Tiles Making Machinery - Corrugated Panel roll forming machine – Linbay Machinery Detail:

Description:

This Roof Panel/Wall Panel Roll Forming Machine can produce any kinds of thickness of corrugated sheets, trapezoidal sheets. Normal thickness is from 0.3-0.8mm. The Corrugated Steel Silo Roll Forming Machine can work with Max. thickness 4.0-5.0mm, its product is used as corrugated steel silo. In South Africa, the Trapezoidal Panel Roll Forming Machine also is known as IBR Roll Forming Machine.

There are different kinds of machine structures, such as Torri stands, Thick wall stands and cast iron stands.

Normal speed is 10-15m/min. Max. Working speed can reach at 25m/min.

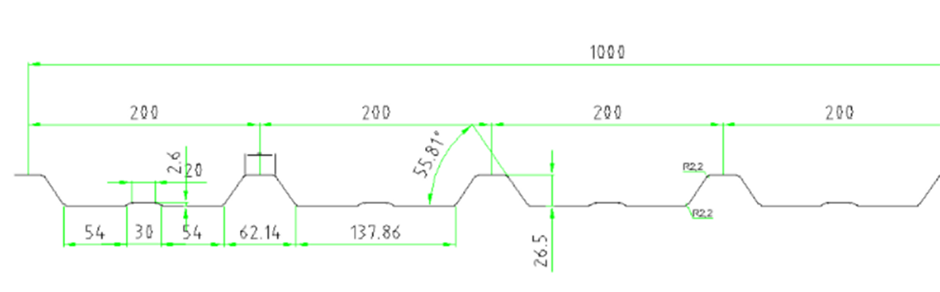

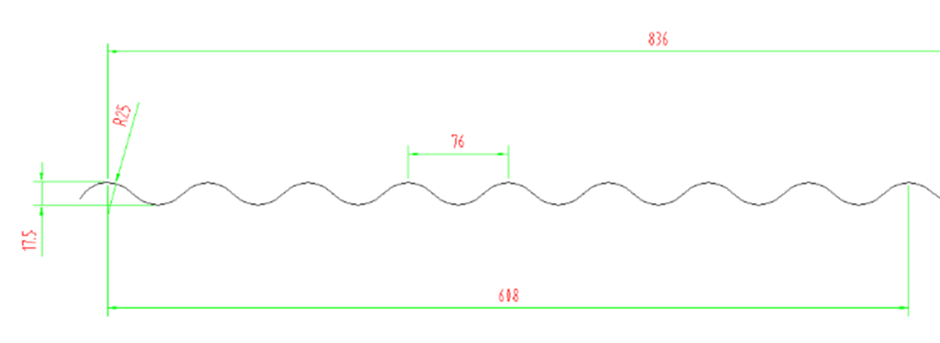

Profile:

Technical specification:

|

Roof panel/Wall panel roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.2-5 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-30 | Or according to your requirement |

|

3 |

Forming station |

18 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

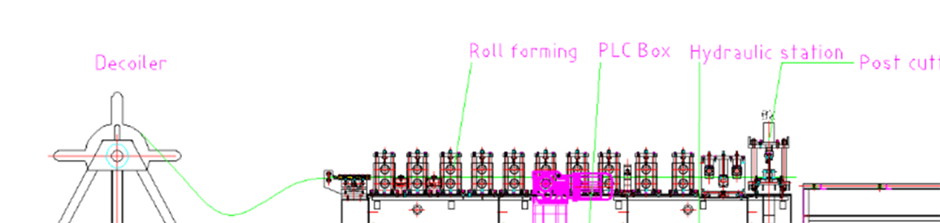

Flow Chart:

Product detail pictures:

Related Product Guide:

Understanding Roll Forming Machines

Roll Forming Machine Design Technology Introduction

We regularly perform our spirit of ''Innovation bringing progress, Highly-quality making certain subsistence, Administration marketing benefit, Credit score attracting customers for Manufactur standard Tiles Making Machinery - Corrugated Panel roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Singapore, South Africa, Casablanca, Corporate goal: Customers' satisfaction is our goal, and sincerely hope to establish long-terms stable cooperative relations with customers to jointly develop the market. Building brilliant tomorrow together!Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!

Send your message to us:

-

Best Price for Roll Forming Line - PU Sandwich...

-

New Delivery for Steel Profile Making Machine -...

-

Free sample for Corrugated Roof Roll Forming Ma...

-

CE Certificate Roof Panel Roll Forming Machiner...

-

Special Design for Corrugated Sheet Roll Formin...

-

Lowest Price for Iron Roll Forming Machine - C...