Manufacturing Companies for Metal Roofing Ridge Cap Roll Forming Machine - PU Sandwich Panel Production Line – Linbay Machinery Detail:

Description:

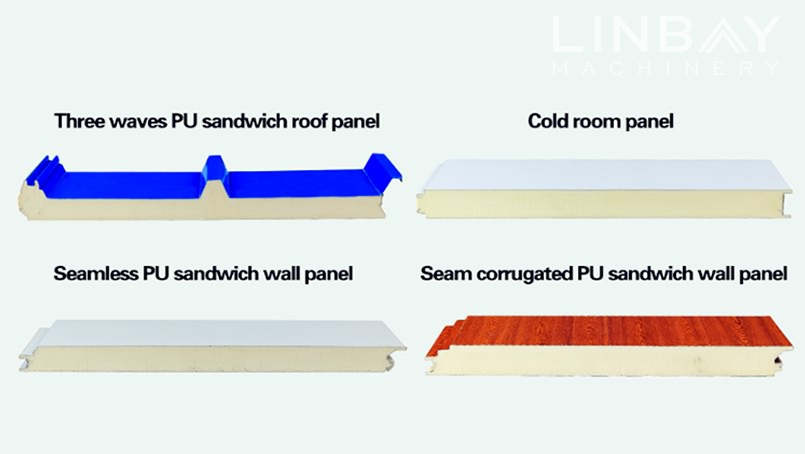

This PU Sandwich Panel Production Line is to manufacture polyurethane or phenol laminated sandwich panel with color steel facings.

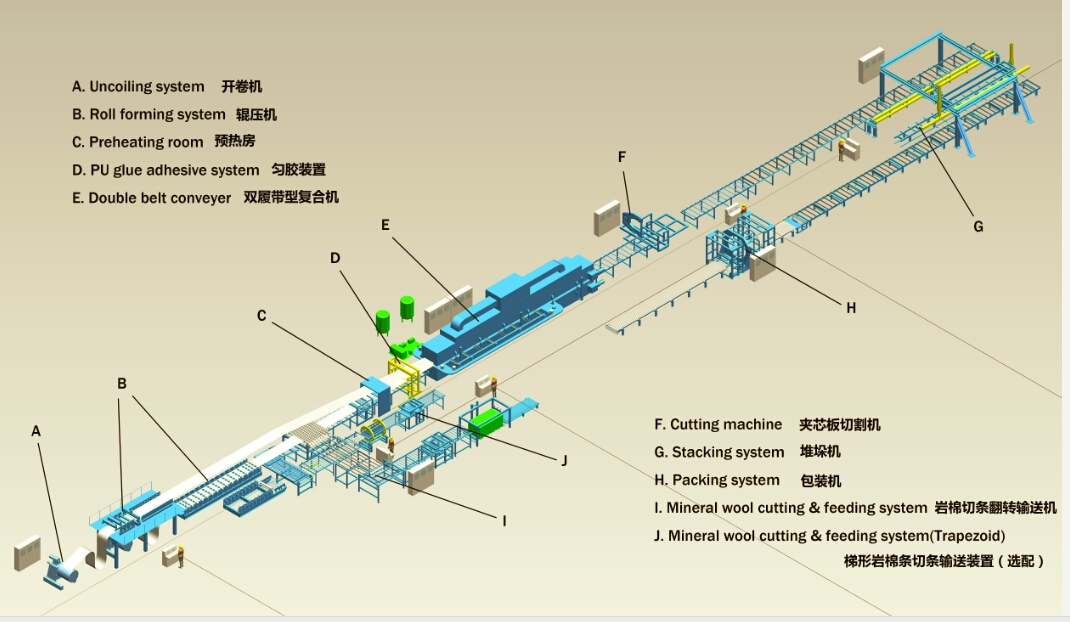

The continuous production line for rigid polyfoam laminated panel with color steel facings is a kind of specialized equipment used for producing color-steel sided sandwich panels with the middle layer of anti-combustion polyurethane, polyisocyanurate or phenolic foam plastic. The thickness of the produced sandwich panel ranges from 0 to 10 mm, the width between 750 to 1000 mm and the length on request. Also we offer Rock Wool Panel Production Line, Glass Wool Panel Production Line.

Profile:

Technical specification:

|

PU Sandwich Panel Production Line |

||

|

NO. |

Composing of product line: |

Amount |

|

1 |

Hydraulic Uncoilers with transporter car |

2 |

|

2 |

Steel sheet transverse cutting device, steel sheet |

2 |

| surface PVC film covering device | ||

|

3 |

Roll forming machine |

4 |

|

4 |

Conveyer |

1 |

|

5 |

Pre-heating room |

1 |

|

6 |

PUR/PIR two components Liquid mixing and |

1 |

| injecting section for foaming (high pressure pump, | ||

| made in China) | ||

|

7 |

Foaming and the PUR/PIR foam maturing |

1 |

| machine /double belt structure 18m length include | ||

| side nylon seal blocks to make 6 kinds thickness | ||

| panel, one set of blocks for supporting roof panel . | ||

|

8 |

Heating and heat insulation system |

1 |

|

9 |

Panel automatically cutting system |

1 |

|

10 |

Electric control system |

1 |

Flow Chart:

Product detail pictures:

Related Product Guide:

Understanding Roll Forming Machines

Cold Roll Forming Machines – New Army in Steel Construction Industry

Our company since its inception, constantly regards product or service high quality as business life, continually improve creation technology, make improvements to product high-quality and consistently strengthen business total high-quality management, in strict accordance together with the national standard ISO 9001:2000 for Manufacturing Companies for Metal Roofing Ridge Cap Roll Forming Machine - PU Sandwich Panel Production Line – Linbay Machinery, The product will supply to all over the world, such as: Buenos Aires, Paris, Boston, With a wide range, good quality, reasonable prices and stylish designs, our items are extensively used in this field and other industries. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success! We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!

Send your message to us:

-

Renewable Design for Container Roller Forming M...

-

High Quality for Rain Gutter Making Machine - ...

-

OEM Manufacturer Trusses Roll Forming Machine -...

-

Factory Directly supply Ibr Sheet Forming Machi...

-

Best-Selling Shelf Roll Forming Machine - Roof...

-

Big discounting Ceiling T Gird Light Keel Makin...