ODM Supplier Gutter Roll Forming Machine - Door frame roll forming machine – Linbay Machinery Detail:

Description:

The Door Frame Roll Forming Machine include Roman Column Door frame Roll Forming Machine, Lace Door Frame Roll Forming Machine, Curved Door Frame Roll Forming Machine, Straight Door Frame Roll Forming Machine, Door Plank Roll Forming Machine etc. We offer any kinds of door frame roll forming machines according to your profile drawing.

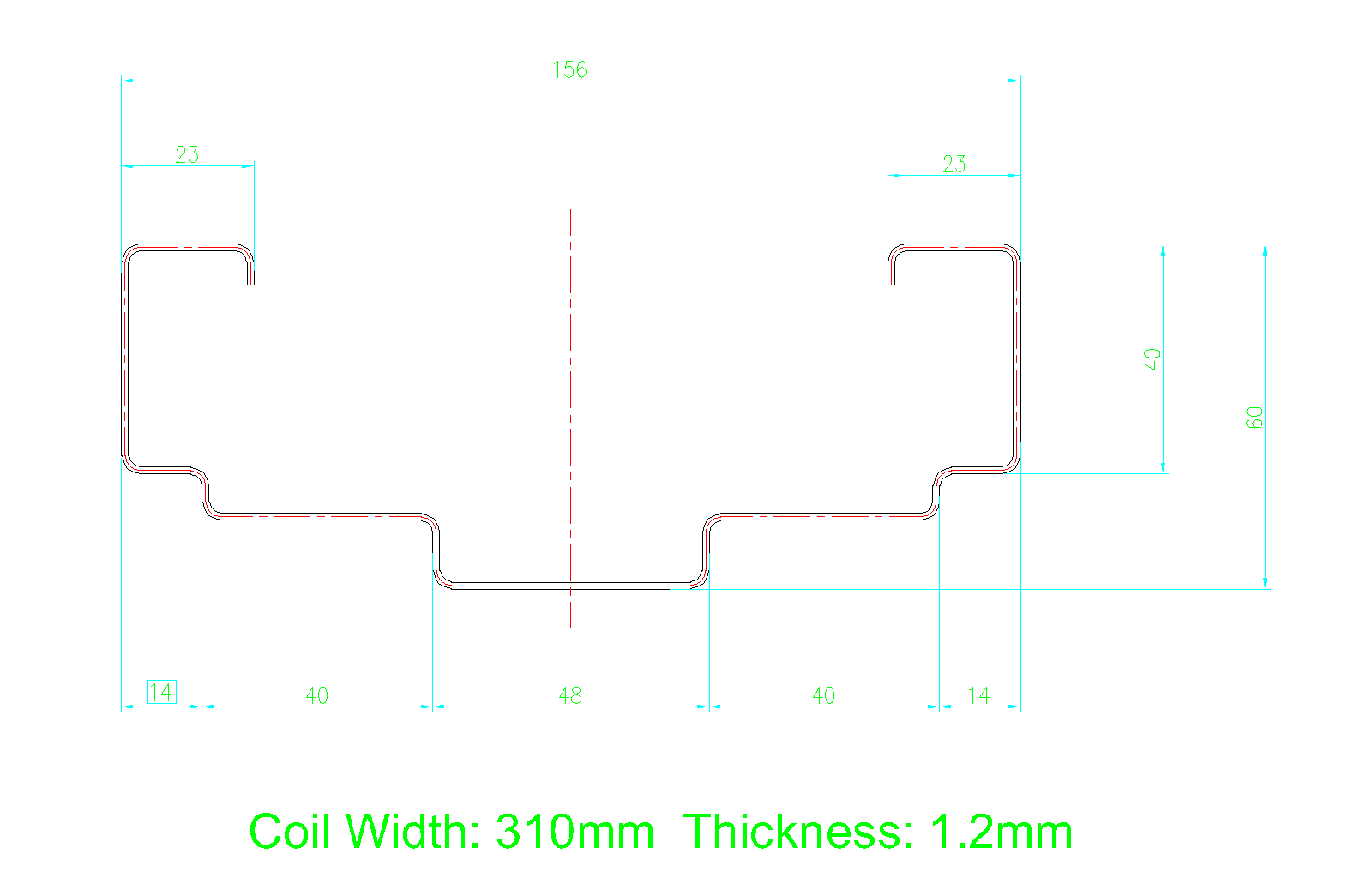

Profile:

Technical specification:

|

Door Frame roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.0-2.0 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

17 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron stationOr torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

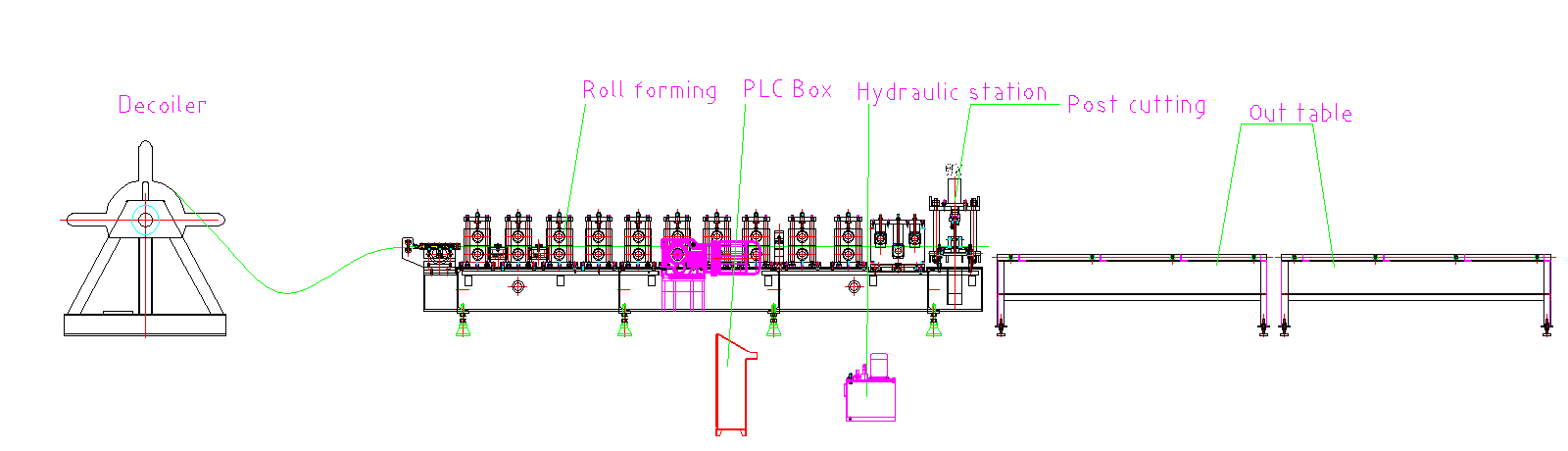

Flow Chart:

Product detail pictures:

Related Product Guide:

Starting and Growing Business With CNC Roll Forming Machine Financing and Leasing

Guide On How To Use a Roll Forming Machine

We're going to dedicate ourselves to offering our esteemed shoppers with the most enthusiastically considerate solutions for ODM Supplier Gutter Roll Forming Machine - Door frame roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: India, Pretoria, Sevilla, We have more than 200 staff including experienced managers, creative designers, sophisticated engineers and skilled workers. Through hard work of all employees for the past 20 years own company grew stronger and stronger. We always apply the "client first" principle. We also always fulfill all contracts to the point and therefore enjoy excellent reputation and trust among our customers. You are very welcome to personally visit our company.We hope to start a business partnership on the basis of mutual benefit and successful development . For more information please do no hesitate to contact us..

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.

Send your message to us:

-

100% Original Factory Solar Panel Bracket Roll ...

-

China Cheap price Temporary Access Equipment -...

-

Top Quality Stud And Track Frame Making Machine...

-

China Manufacturer for Galvanized Metal Studs A...

-

High reputation Roll Former Machine - Roofing ...

-

Low MOQ for Roof Roll Forming Machine - Step B...