OEM/ODM Factory Roll Forming Machinery - Downspout Pipe roll forming machine – Linbay Machinery Detail:

Description:

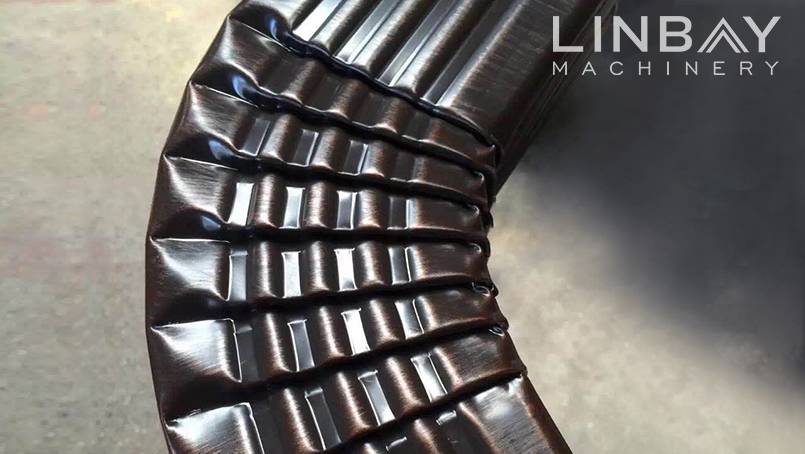

Downspout/Down Pipe Roll Forming Machine can produce the water pipes with perfect surface. It has two types: round pipe and square pipe.

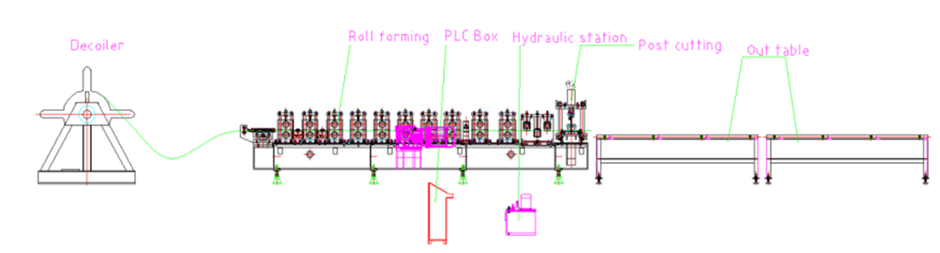

This line include Uncoiler ,Rollforming unit and cutting unit also the Pipe bender unit.

The thickness can be formed Min. 0.3mm thin and Max.2.0mm thick.

The Pipe Bender can be bent the product as 90 degree and retracted for connecting pipe ends.

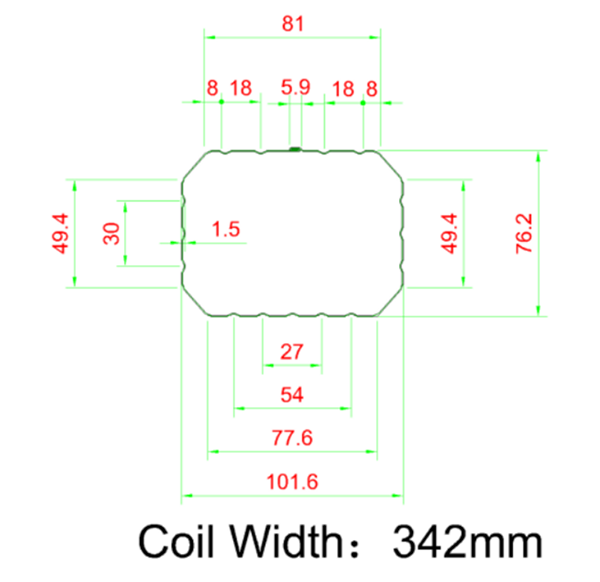

Profile:

Technical specification:

|

Downspout Pipe/Round pipe/ Square pipe roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-2 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

19 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

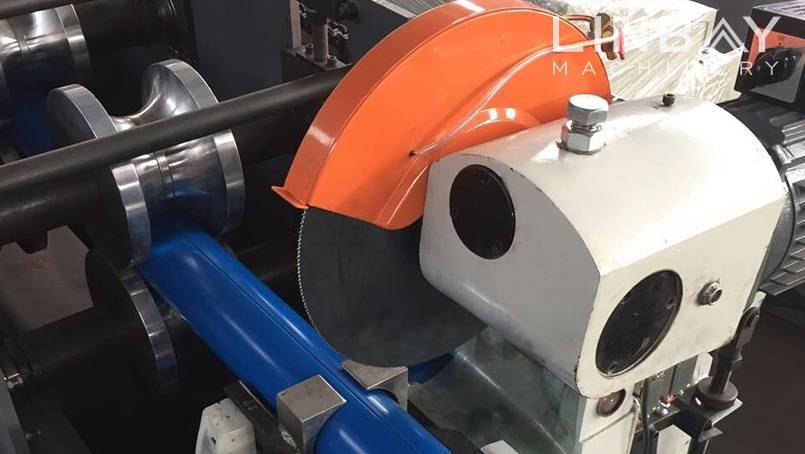

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

Flow Chart:

Product detail pictures:

Related Product Guide:

Roll Forming Machine Design Technology Introduction

Guide On How To Use a Roll Forming Machine

We have a professional, efficiency team to provide quality service for our customer. We always follow the tenet of customer-oriented, details-focused for OEM/ODM Factory Roll Forming Machinery - Downspout Pipe roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Rio de Janeiro, Jakarta, Hyderabad, Many years of work experience, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.

Send your message to us:

-

ODM Manufacturer Electrical Rolling Machine - ...

-

China wholesale Professional Roll Forming Machi...

-

Massive Selection for Rolling Machine Price - ...

-

China wholesale Corrugated Machine Price - Cab...

-

2018 New Style Double Layer Cold Tile Steel She...

-

Wholesale Dealers of Double Layer Color Steel T...