OEM/ODM Manufacturer Z Purlin Roll Forming Machine - Gutter roll forming machine – Linbay Machinery Detail:

Description:

Gutter Roll Forming Machine normally work with 0.4-0.6mm thickness raw material to make gutters and drains. Normal working speed is aroun 10-20m/min. We adopt torri stand structure, it’s more beautiful and more table when the machine working.

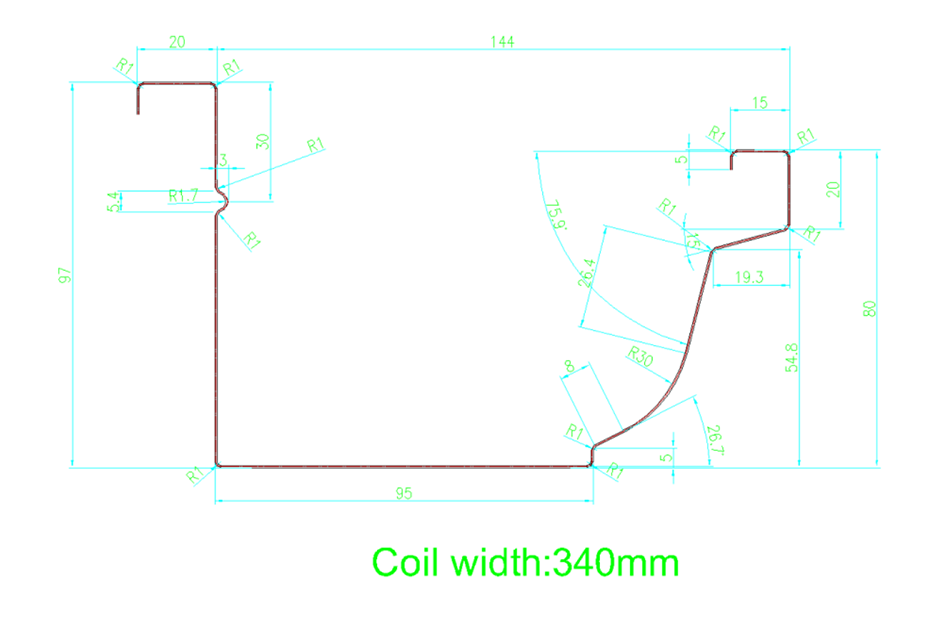

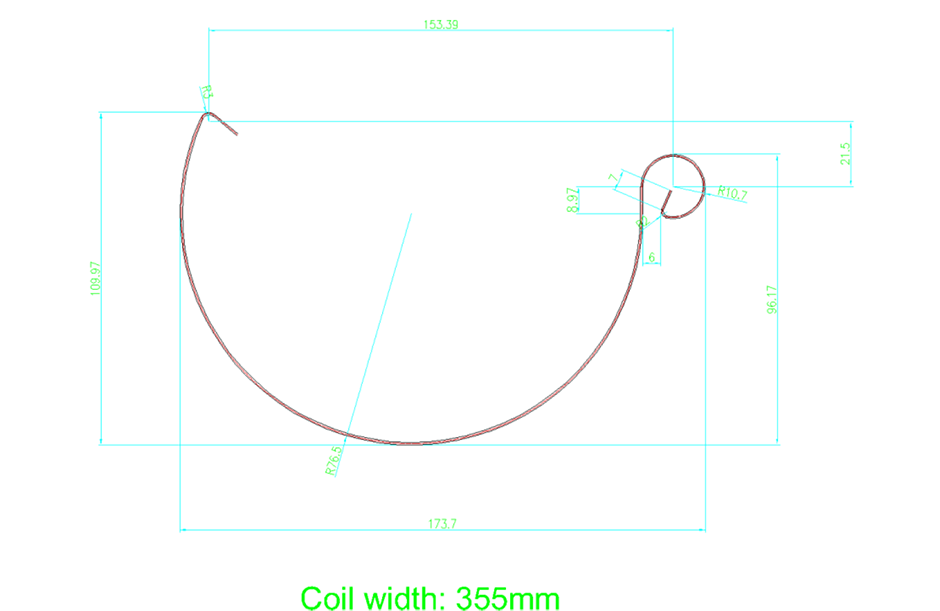

Profile:

Technical specification:

|

Gutter roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.4-0.6 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

19 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

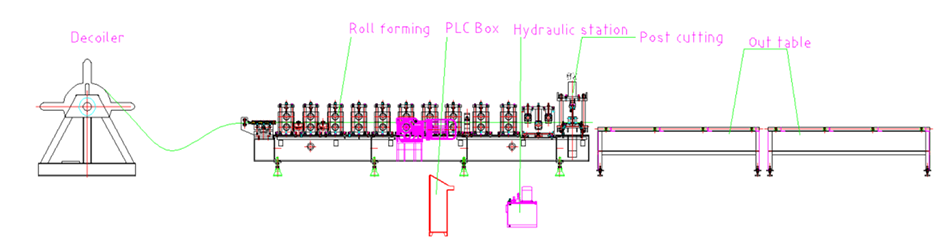

Flow Chart:

Product detail pictures:

Related Product Guide:

Roll Forming Machine Design Technology Introduction

Starting and Growing Business With CNC Roll Forming Machine Financing and Leasing

The customer satisfaction is our primary target. We uphold a consistent level of professionalism, quality, credibility and service for OEM/ODM Manufacturer Z Purlin Roll Forming Machine - Gutter roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Israel, Swiss, Costa Rica, With the enterprising spirit of" high efficiency, convenience, practicality and innovation", and in line with such serving guidance of "good quality but better price, " and "global credit", we are striving to cooperate with the automobile parts companies all over the world to make a win-win partnership.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!

Send your message to us:

Write your message here and send it to us

-

Factory source Aluzinc Roofing Sheet Roll Formi...

-

Popular Design for Steel Tile Forming - Metal ...

-

8 Years Exporter Double Roofing Sheet Machine -...

-

Cheap PriceList for Aluminium Gutter Roll Formi...

-

Factory For Light Keel Profiles Production Mach...

-

Hot sale Factory Hydraulic Arch Machine - Step...