PriceList for 836 Corrugated Machine - Gutter roll forming machine – Linbay Machinery Detail:

Description:

Gutter Roll Forming Machine normally work with 0.4-0.6mm thickness raw material to make gutters and drains. Normal working speed is aroun 10-20m/min. We adopt torri stand structure, it’s more beautiful and more table when the machine working.

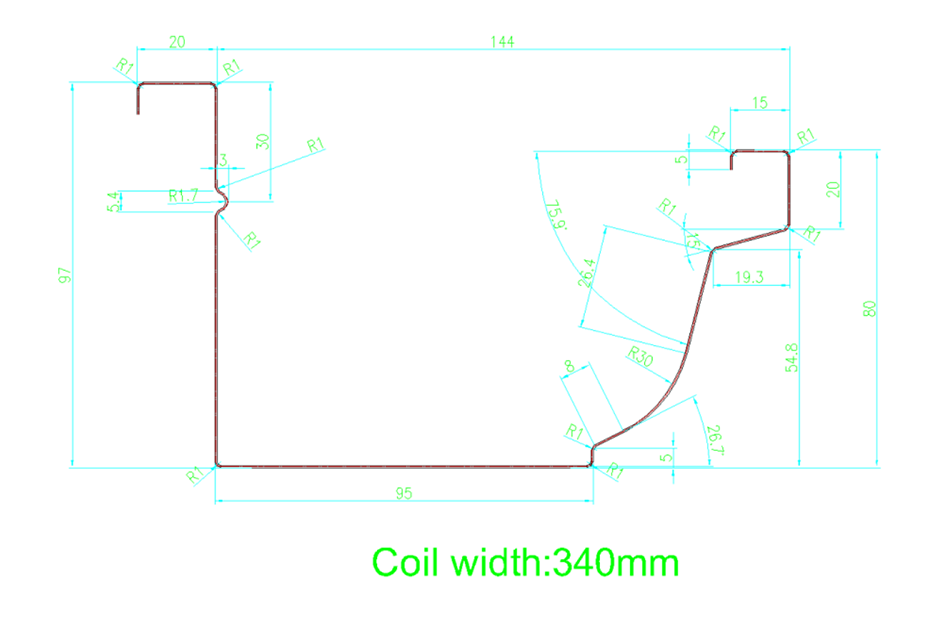

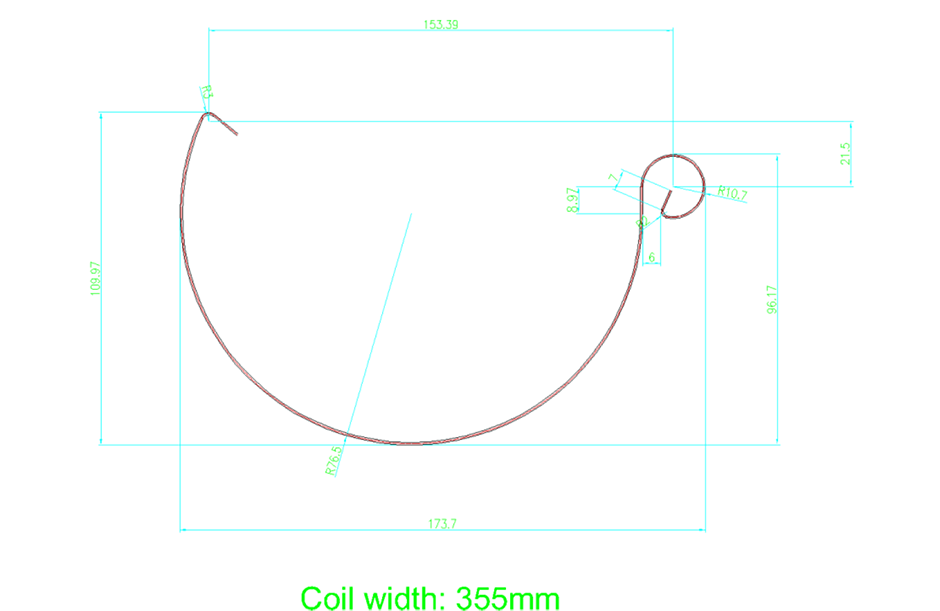

Profile:

Technical specification:

|

Gutter roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.4-0.6 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

19 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

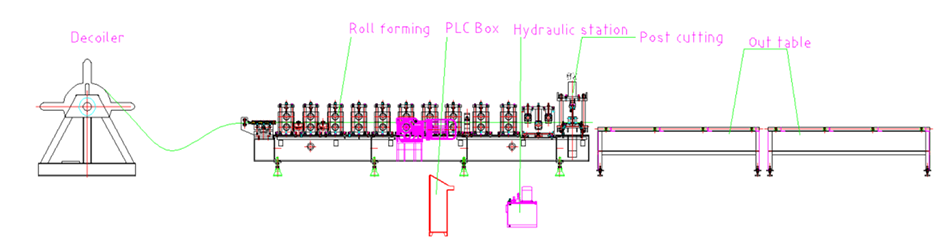

Flow Chart:

Product detail pictures:

Related Product Guide:

Roll Forming Machine Design Technology Introduction

Understanding Roll Forming Machines

With our loaded encounter and considerate services, we have now been recognized as a trustworthy supplier for lots of worldwide consumers for PriceList for 836 Corrugated Machine - Gutter roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Romania, Cannes, Eindhoven, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to offer our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We are ready to face the worries and make the improve to understand all the possibilities in international trade.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.

Send your message to us:

Write your message here and send it to us

-

Reliable Supplier Used Metal Roofing Panel Roll...

-

ODM Factory Tile Roof Machine - Ridge Cap roll...

-

ODM Supplier Purlin Roll Forming Machine - Doo...

-

Factory source Aluzinc Roofing Sheet Roll Formi...

-

Discount wholesale Roofing Panel Machine - Rid...

-

Popular Design for Steel Tile Forming - PU San...