PriceList for Metal Sheet Roll Former Sugo - Shelf Rack roll forming machine – Linbay Machinery Detail:

Description:

Goods Shelf Roll Forming Machine including Shelf Roll Forming Machine, Pallet Rack Roll Forming Machine.Pallet rack can both store multi-veriety goods with small quantity and also unified goods with big quantity. Normally thickness can be formed at 2.5mm and the speed is about 20-30m/min.This machine is widely used in high warehouses.

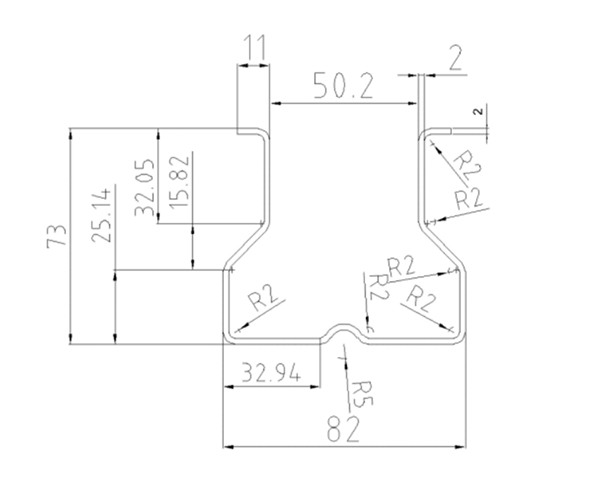

Profile:

Technical specification:

|

Warehouse Pallet Rack/Goods Shelf Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-2.5 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

20 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel station |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

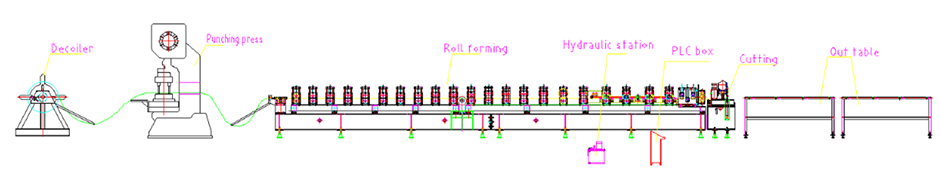

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Roll Forming Machine Design Technology Introduction

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for PriceList for Metal Sheet Roll Former Sugo - Shelf Rack roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Hamburg, European, Morocco, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will provide our best service to satisfy all your needs! You should contact us right away!

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.

Send your message to us:

-

Top Quality Floor Decking Machine - PU Sandwic...

-

Wholesale OEM Double Roll Forming Machine - C ...

-

Online Exporter Cold Rolling Steel Bar Making M...

-

Good User Reputation for Metal Roofing Machines...

-

Competitive Price for Sheet Roll Forming Machin...

-

Best Price for Glazed Roofing Tile Roll Forming...