Quoted price for Stud And Track Roll Formed Machine C Channel Machine - Corrugated Panel roll forming machine – Linbay Machinery Detail:

Description:

This Roof Panel/Wall Panel Roll Forming Machine can produce any kinds of thickness of corrugated sheets, trapezoidal sheets. Normal thickness is from 0.3-0.8mm. The Corrugated Steel Silo Roll Forming Machine can work with Max. thickness 4.0-5.0mm, its product is used as corrugated steel silo. In South Africa, the Trapezoidal Panel Roll Forming Machine also is known as IBR Roll Forming Machine.

There are different kinds of machine structures, such as Torri stands, Thick wall stands and cast iron stands.

Normal speed is 10-15m/min. Max. Working speed can reach at 25m/min.

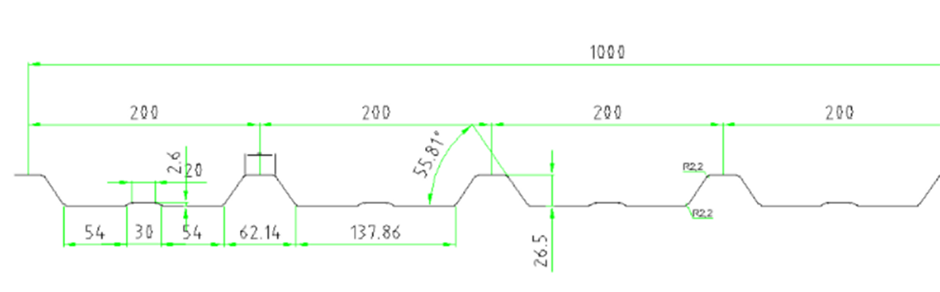

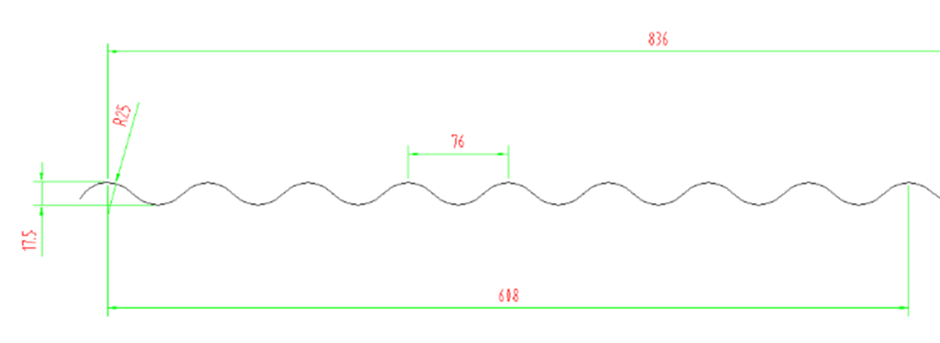

Profile:

Technical specification:

|

Roof panel/Wall panel roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.2-5 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-30 | Or according to your requirement |

|

3 |

Forming station |

18 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

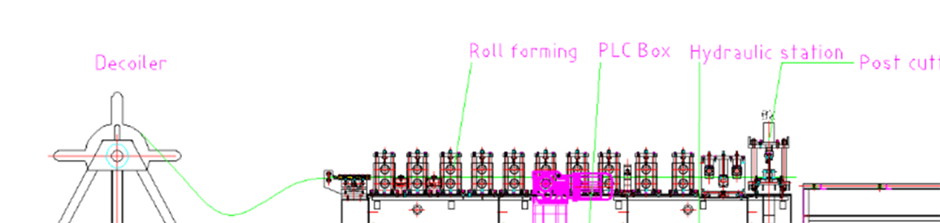

Flow Chart:

Product detail pictures:

Related Product Guide:

Roll Forming Machine Design Technology Introduction

Starting and Growing Business With CNC Roll Forming Machine Financing and Leasing

Our rewards are lower costs,dynamic profits team,specialised QC,potent factories,high-quality services for Quoted price for Stud And Track Roll Formed Machine C Channel Machine - Corrugated Panel roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Southampton, Boston, Colombia, We have a dedicated and aggressive sales team, and many branches, catering to our customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.

Send your message to us:

-

Wholesale OEM/ODM Steel Sheet Roll Forming Mach...

-

Big discounting Metal Badge Making Machine - S...

-

Europe style for Steel Glazed Tile Roll Forming...

-

Wholesale OEM/ODM Roofing Sheets Machine - Sus...

-

Rapid Delivery for Rolling Shutter Slats Roll F...

-

Newly Arrival Roofing Tile Forming Machine - C...