Rapid Delivery for Door Frame Forming Machines - Gutter roll forming machine – Linbay Machinery Detail:

Description:

Gutter Roll Forming Machine normally work with 0.4-0.6mm thickness raw material to make gutters and drains. Normal working speed is aroun 10-20m/min. We adopt torri stand structure, it’s more beautiful and more table when the machine working.

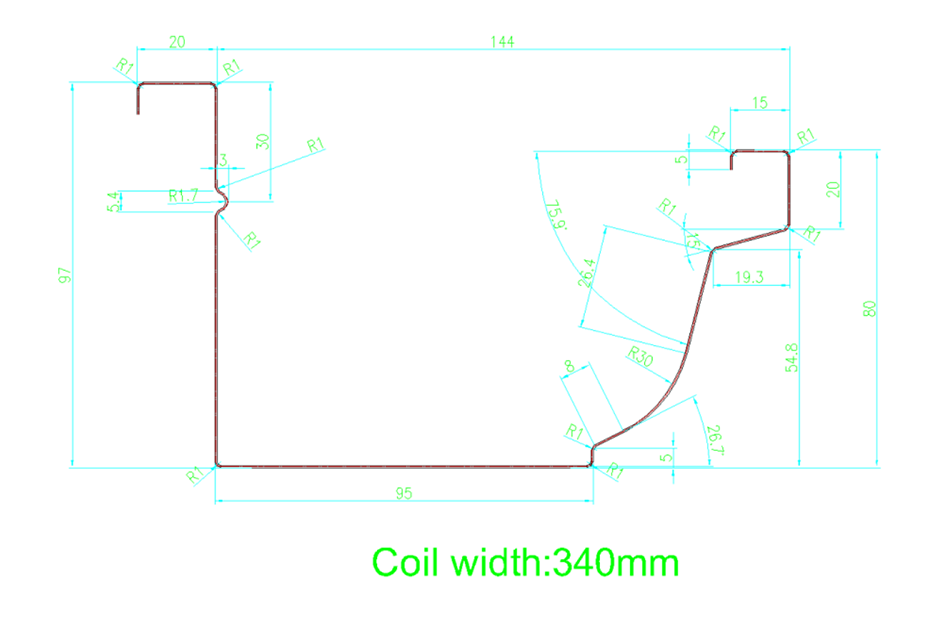

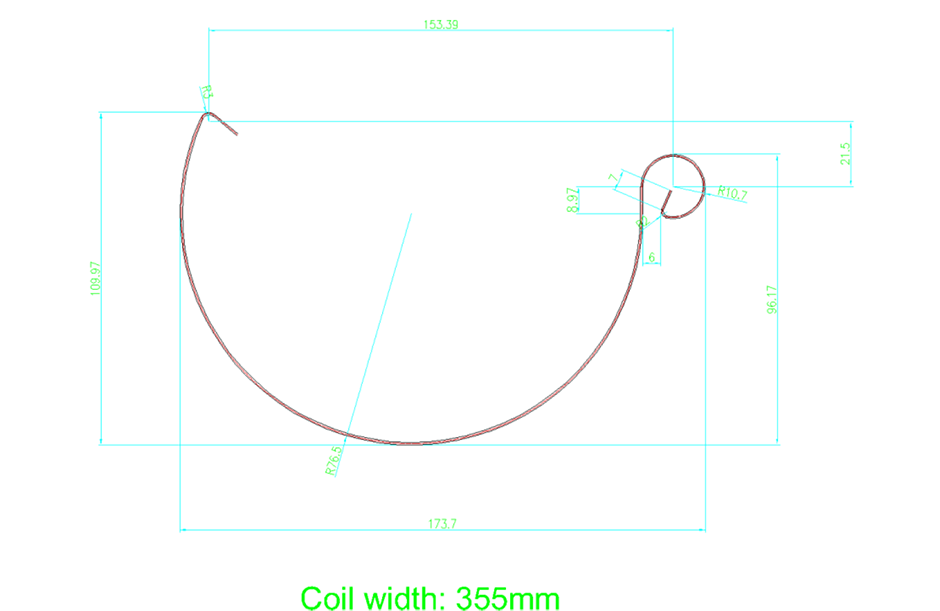

Profile:

Technical specification:

|

Gutter roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.4-0.6 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

19 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

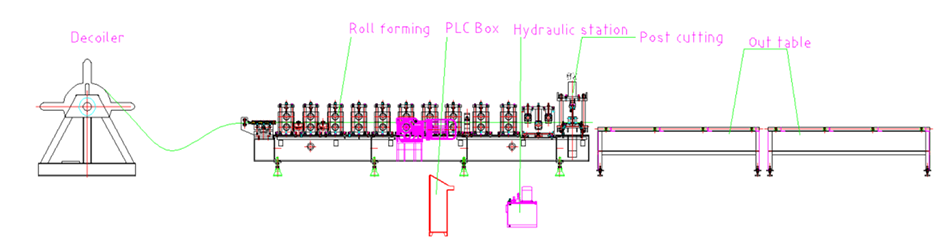

Flow Chart:

Product detail pictures:

Related Product Guide:

Cold Roll Forming Machines – New Army in Steel Construction Industry

Guide On How To Use a Roll Forming Machine

Every single member from our large efficiency profits team values customers' requirements and organization communication for Rapid Delivery for Door Frame Forming Machines - Gutter roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Niger, Norwegian, Denmark, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.

Send your message to us:

Write your message here and send it to us

-

Factory Cheap Hot Steel Silo Machine - Highway...

-

Discountable price Picture Frame Making Machine...

-

China Gold Supplier for Metal Stud Roll Forming...

-

OEM Manufacturer Steel Shutter Door Roll Formin...

-

OEM/ODM Supplier Galvanized Floor Decking Roll ...

-

China Manufacturer for C Shape Purlin Guide Rai...