Renewable Design for Container Roller Forming Machine - Corrugated Panel roll forming machine – Linbay Machinery Detail:

Description:

This Roof Panel/Wall Panel Roll Forming Machine can produce any kinds of thickness of corrugated sheets, trapezoidal sheets. Normal thickness is from 0.3-0.8mm. The Corrugated Steel Silo Roll Forming Machine can work with Max. thickness 4.0-5.0mm, its product is used as corrugated steel silo. In South Africa, the Trapezoidal Panel Roll Forming Machine also is known as IBR Roll Forming Machine.

There are different kinds of machine structures, such as Torri stands, Thick wall stands and cast iron stands.

Normal speed is 10-15m/min. Max. Working speed can reach at 25m/min.

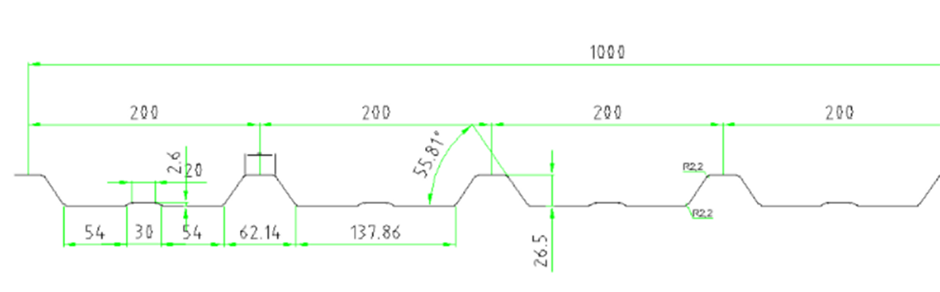

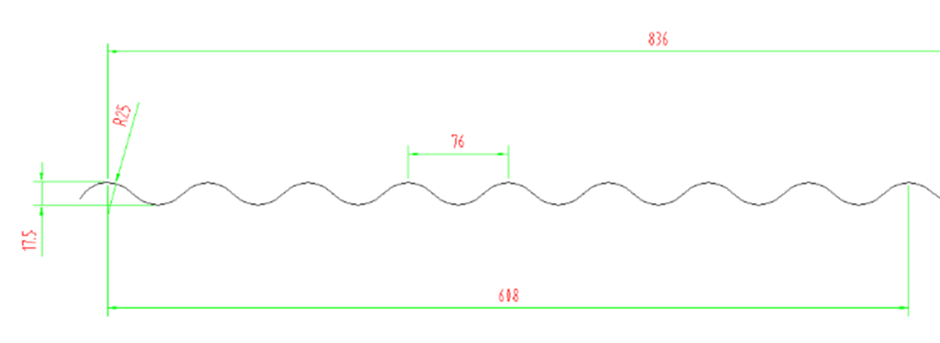

Profile:

Technical specification:

|

Roof panel/Wall panel roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.2-5 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-30 | Or according to your requirement |

|

3 |

Forming station |

18 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

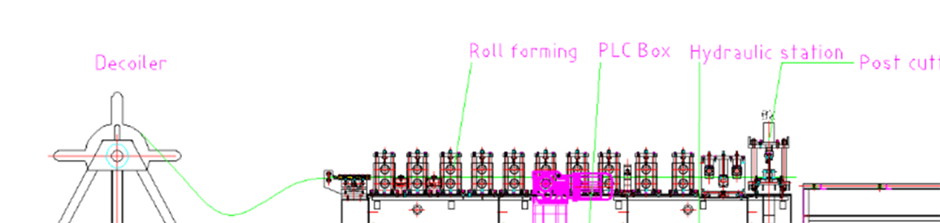

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Roll Forming Machine Design Technology Introduction

From the past few years, our firm absorbed and digested sophisticated technologies equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted into the growth of Renewable Design for Container Roller Forming Machine - Corrugated Panel roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Hyderabad, Mombasa, Malaysia, Our experience makes us important in our customer eyes. Our quality speaks itself the properties like it do not tangle, shed or breakdown, so that are our customers will always be confident while placing an order.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.

Send your message to us:

-

PriceList for Glass Wool Panel Production Line ...

-

Best Price for Corrugated Panel Roll Forming Ma...

-

Factory best selling Roofing Sheet Machine - C...

-

Special Price for Steel Purlin Roll Forming Mac...

-

Factory Free sample Cold Roll Former Machine -...

-

Well-designed Standing Seam Metal Roof Machine ...