Renewable Design for Ridge Cap Roll Forming Machine - Roofing Tile roll forming machine – Linbay Machinery Detail:

Description:

This Corrugated Tile/Roofing tile Roll Forming Machine produce more artistic and more popular corrugation sheets in many countries. It can be formed materail thickness as 0.3-0.8mm.

We have two types of cutting system, one is normal cut and other is 3D cut. From the pictures, you can see 3D cut maintains the profile shape more beautiful than normal horizontal cut. Besides all of the parts are controlled by PLC and automatically.

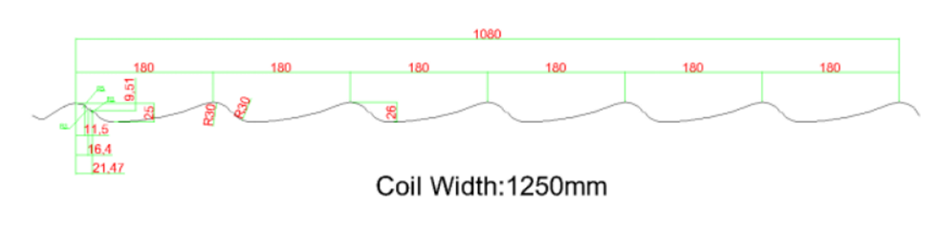

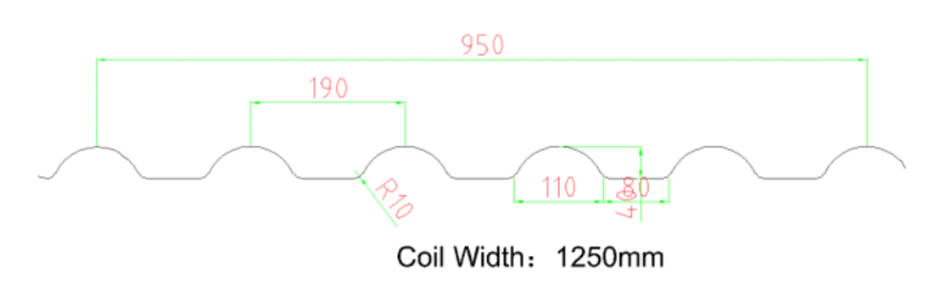

Profile:

Technical specification:

|

Corrugated Tile/Roofing tile Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.3-0.8 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-25 | Or according to your requirement |

|

3 |

Forming station |

According to your profile | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Wall panel station | Forged Iron station

Or torri stand structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

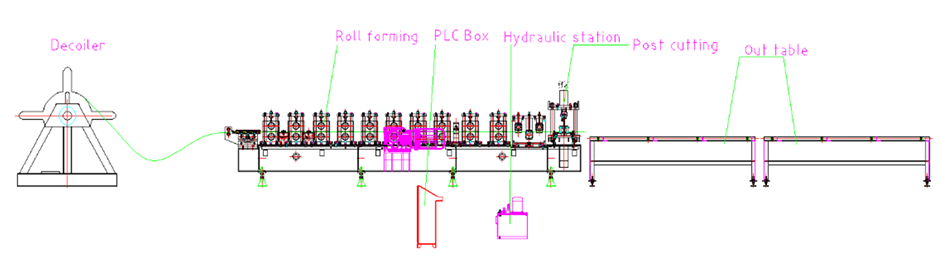

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Starting and Growing Business With CNC Roll Forming Machine Financing and Leasing

"Control the quality by the details, show the strength by quality". Our company has strived to establish a highly efficient and stable staff team and explored an effective quality control process for Renewable Design for Ridge Cap Roll Forming Machine - Roofing Tile roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Nepal, Ukraine, Namibia, We also have the strong ability of integration to supply our best service, and plan to build the warehouse in the different countries around the world, that will probably be more conveniently to service our customers.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,

Send your message to us:

-

Reasonable price for Roll Up Garage Door Opener...

-

Manufacturer of Screw-joint Machine - Cable Tr...

-

Newly Arrival Roll Forming Machine For Gutter -...

-

Popular Design for Racking Upright Cold Roll Fo...

-

Free sample for Pu Foam Shutter Machine - Roof...

-

Trending Products Aluminium Roof Roll Forming M...