Special Price for Aluminium Cold Roll Forming Machine - Gutter roll forming machine – Linbay Machinery Detail:

Description:

Gutter Roll Forming Machine normally work with 0.4-0.6mm thickness raw material to make gutters and drains. Normal working speed is aroun 10-20m/min. We adopt torri stand structure, it’s more beautiful and more table when the machine working.

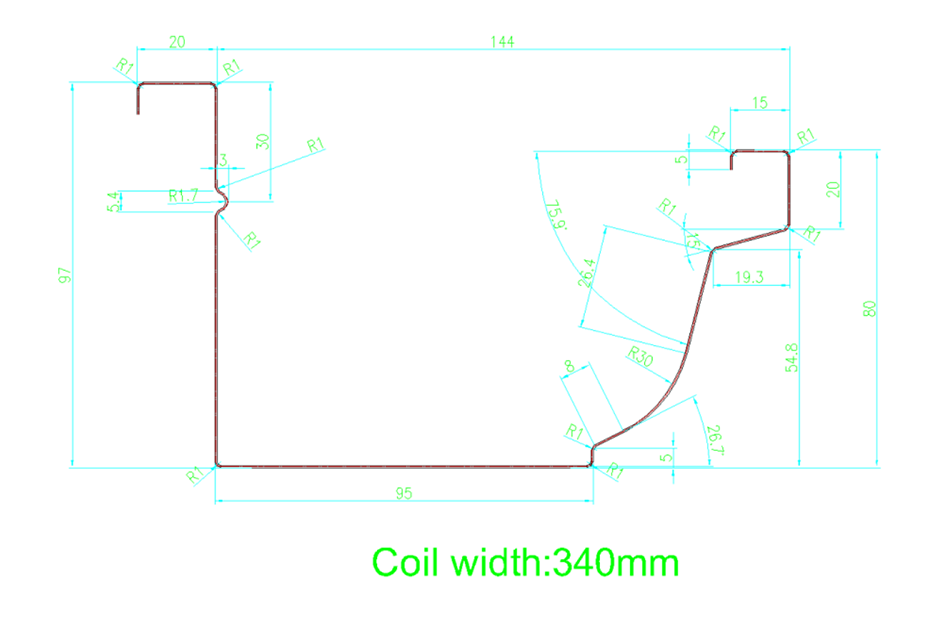

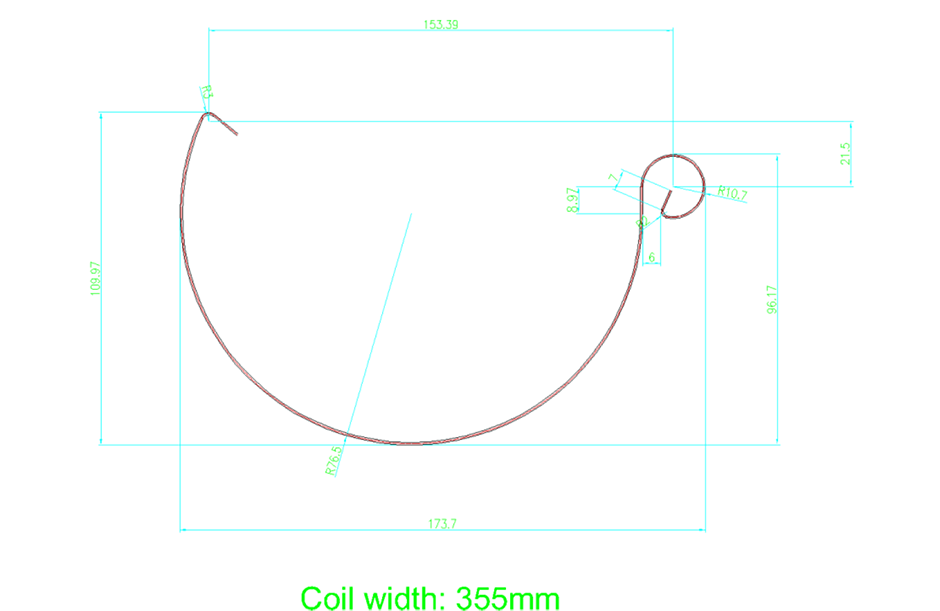

Profile:

Technical specification:

|

Gutter roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.4-0.6 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

19 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

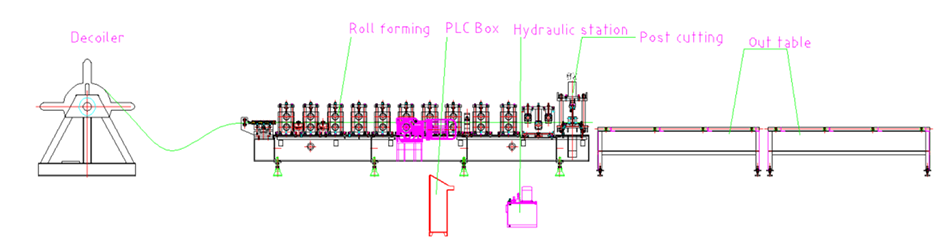

Flow Chart:

Product detail pictures:

Related Product Guide:

Cold Roll Forming Machines – New Army in Steel Construction Industry

Roll Forming Machine Design Technology Introduction

To be the stage of realizing dreams of our employees! To build a happier, far more united and far more specialist team! To reach a mutual profit of our customers, suppliers, the society and ourselves for Special Price for Aluminium Cold Roll Forming Machine - Gutter roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Salt Lake City, Armenia, Belgium, By integrating manufacturing with foreign trade sectors, we can offer total customer solutions by guaranteeing the delivery of right items to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.

Send your message to us:

Write your message here and send it to us

-

Manufactur standard Roof Panel Roll Forming - ...

-

Original Factory Changeable C Purlin Roll Formi...

-

New Arrival China Electric Scaffolding - Suspe...

-

Factory Supply Arch Steel Sheet Forming Machine...

-

OEM/ODM Manufacturer Z Purlin Roll Forming Mach...

-

Europe style for Ridge Cap Steel Framing Roll F...