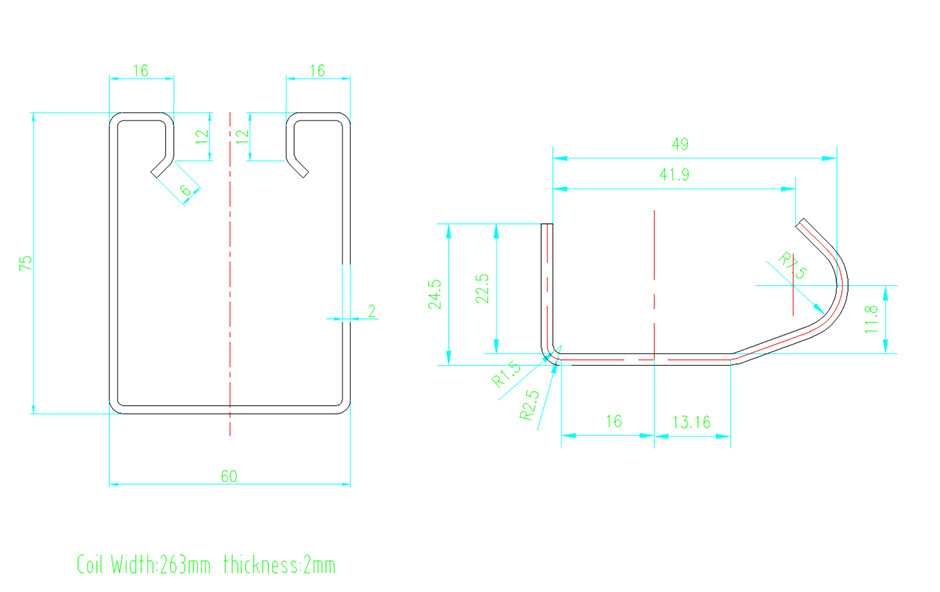

Super Lowest Price Powered Suspended Platform - Strut and Rail roll forming machine – Linbay Machinery Detail:

Description:

Steel Strut&Rail Roll Fomring Machine includ Door Rail Roll Fomring Machine, Steel C Channel Roll Forming Machine, Solar Rack Roll Forming Machine etc. The working thickness can be 1.5-2.5mm. The Max. working speed can be 25m/min. We adopt gearbox driving system to keep our machine work with high speed and prolong the service life.

Profile:

Technical specification:

|

Steel Strut& Rail roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-2.5 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

17 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Gearbox drive | Chain drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

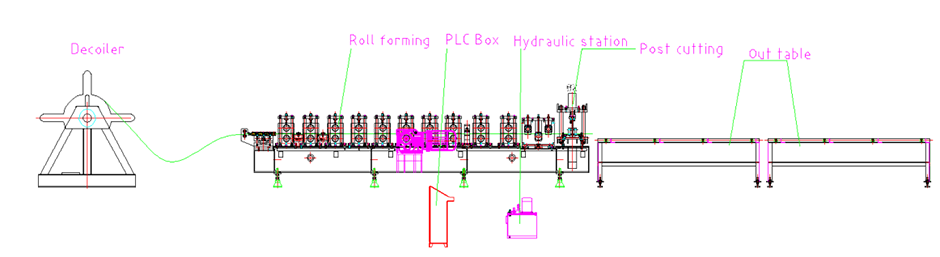

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Roll Forming Machine Design Technology Introduction

"Based on domestic market and expand overseas business" is our development strategy for Super Lowest Price Powered Suspended Platform - Strut and Rail roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: South Africa, Florence, Iceland, We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.

Send your message to us:

-

Popular Design for Light Gauge Steel Roll Formi...

-

OEM Factory for Manual Roof Tile Making Machine...

-

Reasonable price Scaffolding Powered Cradle - ...

-

Hot-selling Rroof Ridge Cap Roll Forming Machin...

-

Trending Products Roof Sheet Roll Forming Machi...

-

Wholesale Colored Steel Sheet Roll Form Machine...