Super Purchasing for Poster Rolling Machine - Gutter roll forming machine – Linbay Machinery Detail:

Description:

Gutter Roll Forming Machine normally work with 0.4-0.6mm thickness raw material to make gutters and drains. Normal working speed is aroun 10-20m/min. We adopt torri stand structure, it’s more beautiful and more table when the machine working.

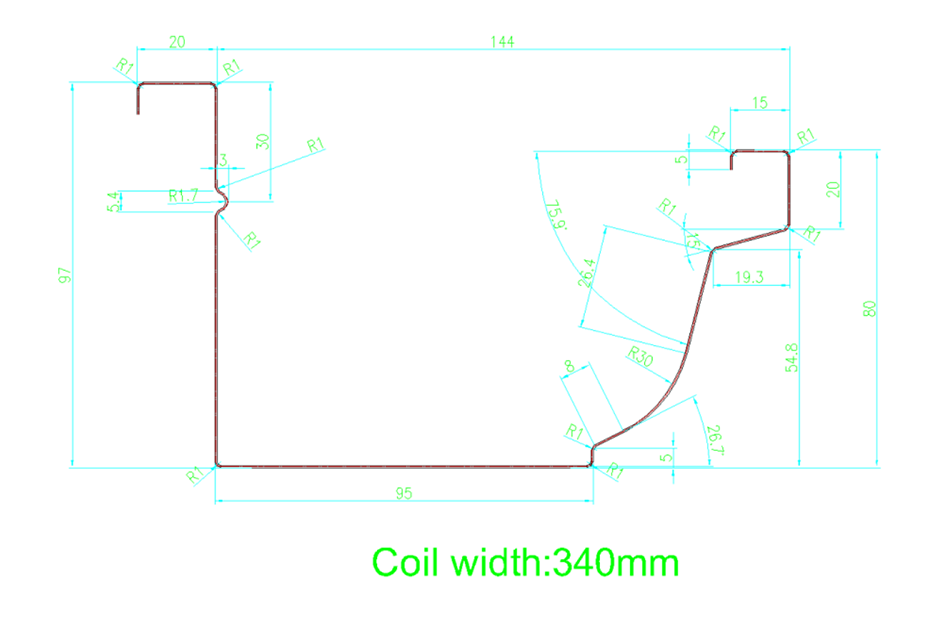

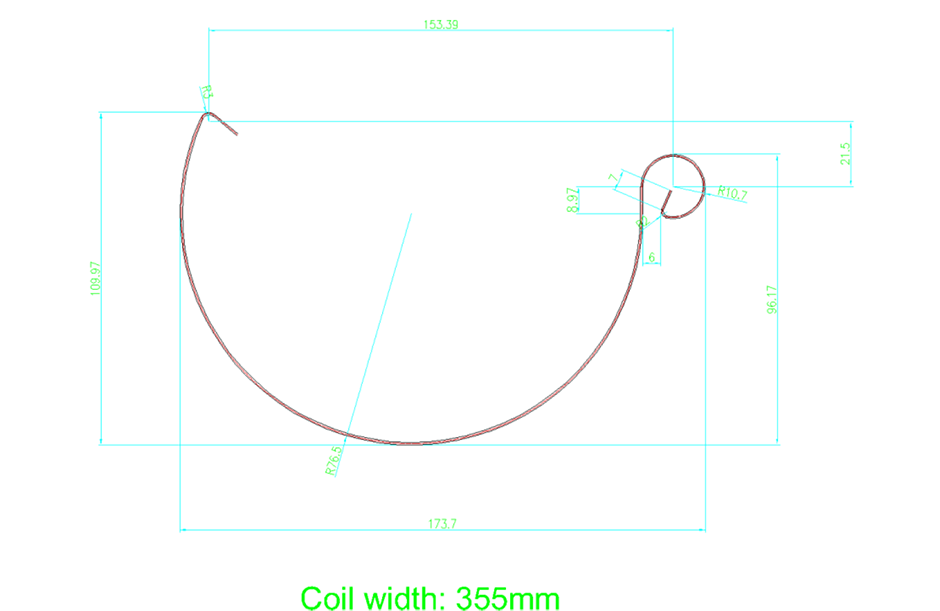

Profile:

Technical specification:

|

Gutter roll forming machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.4-0.6 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

19 | According to your profile |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel structure |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

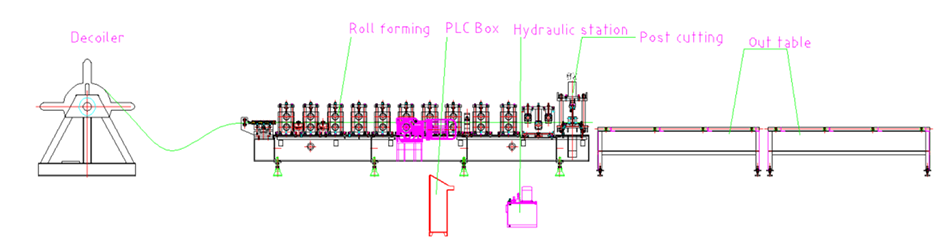

Flow Chart:

Product detail pictures:

Related Product Guide:

Roll Forming Machine Design Technology Introduction

Starting and Growing Business With CNC Roll Forming Machine Financing and Leasing

The company upholds the philosophy of "Be No.1 in quality, be rooted on credit and trustworthiness for growth", will continue to serve old and new customers from home and overseas whole-heatedly for Super Purchasing for Poster Rolling Machine - Gutter roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Tunisia, Netherlands, European, With many years good service and development, we have a qualified international trade sales team. Our goods have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. Looking forward to build up a good and long term cooperation with you in coming future!

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!

Send your message to us:

Write your message here and send it to us

-

Hot sale Factory Cladding Forming Machine - Z ...

-

Massive Selection for Omega Profile Roll Formin...

-

China Manufacturer for Parts Of Door Roll Shutt...

-

18 Years Factory Roof Sheet Making Machines - ...

-

Supply OEM/ODM Aluminum Roll Roofing - Downspo...

-

Competitive Price for Color Glazed Tile Roll Fo...