Supply OEM Aluminum Composite Panel Cutting Machine - Step Beam roll forming machine – Linbay Machinery Detail:

Description:

Square Pipe Roll Forming Machine include Step Beam Roll Formng Machine. Beam rack can both store multi-veriety goods with small quantity and also unified goods with big quantity. And square pipe can be used as down pipe also. Normally thickness can be formed at 1.5-3mm and the speed is about 10-20m/min.This machine is widely used in high warehouses.

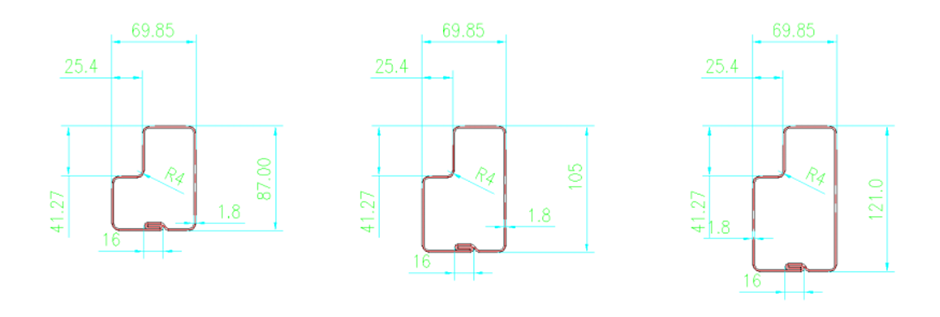

Profile:

Technical specification:

|

Warehouse Step Beam/Square Pipe Roll Forming Machine |

|||

|

No. |

Item |

Specification |

Optional |

|

1 |

Suitable material |

Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):1.5-1.8,1.5-3 | |||

| Yield strength: 250 – 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

|

2 |

Nominal forming speed(m/min) |

10-20 | Or according to your requirement |

|

3 |

Forming station |

31 | |

|

4 |

Decoiler |

Manual decoiler | Hydraulic decoiler or double head decoiler |

|

5 |

Main machine motor |

Sino-German Brand | Siemens |

|

6 |

PLC brand |

Panasonic | Siemens |

|

7 |

Inverter brand |

Yaskawa | |

|

8 |

Driving system |

Chain drive | Gearbox drive |

|

9 |

Rollers’ materail |

Steel #45 | GCr15 |

|

10 |

Station structure |

Torri stand structure | Forged Iron station

Or Wall panel station |

|

11 |

Punching system |

No | Hydraulic punching station or Punching press |

|

12 |

Cutting system |

Post-cutting | Pre-cutting |

|

13 |

Power supply requirement |

380V 60Hz | Or according to your requirement |

|

14 |

Machine color |

Industrial blue | Or according to your requirement |

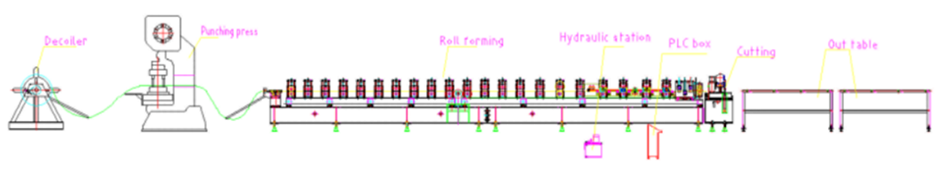

Flow Chart:

Product detail pictures:

Related Product Guide:

Guide On How To Use a Roll Forming Machine

Understanding Roll Forming Machines

We constantly believe that one's character decides products' high quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Supply OEM Aluminum Composite Panel Cutting Machine - Step Beam roll forming machine – Linbay Machinery, The product will supply to all over the world, such as: Surabaya, United States, Ecuador, We can meet the various needs of customers at home and abroad. We welcome new and old customers to come to consult & negotiate with us. Your satisfaction is our motivation! Allow us to work together to write a brilliant new chapter!

1. Decoiler

2. Feeding

3.Punching

4. Roll forming stands

5. Driving system

6. Cutting system

Others

Out table

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.

Send your message to us:

-

Big Discount C Shape Forming Machine - Roofing...

-

8 Years Exporter Roll Bending Machine - Roofin...

-

Factory For Roofing Corrugated Tile Forming Mac...

-

China wholesale Colored Steel Tile Roll Forming...

-

OEM China Wall And Roof Machine - Step Beam ro...

-

Chinese wholesale Aluminum Roller Shutter - Ri...